Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Surgical Dressing Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

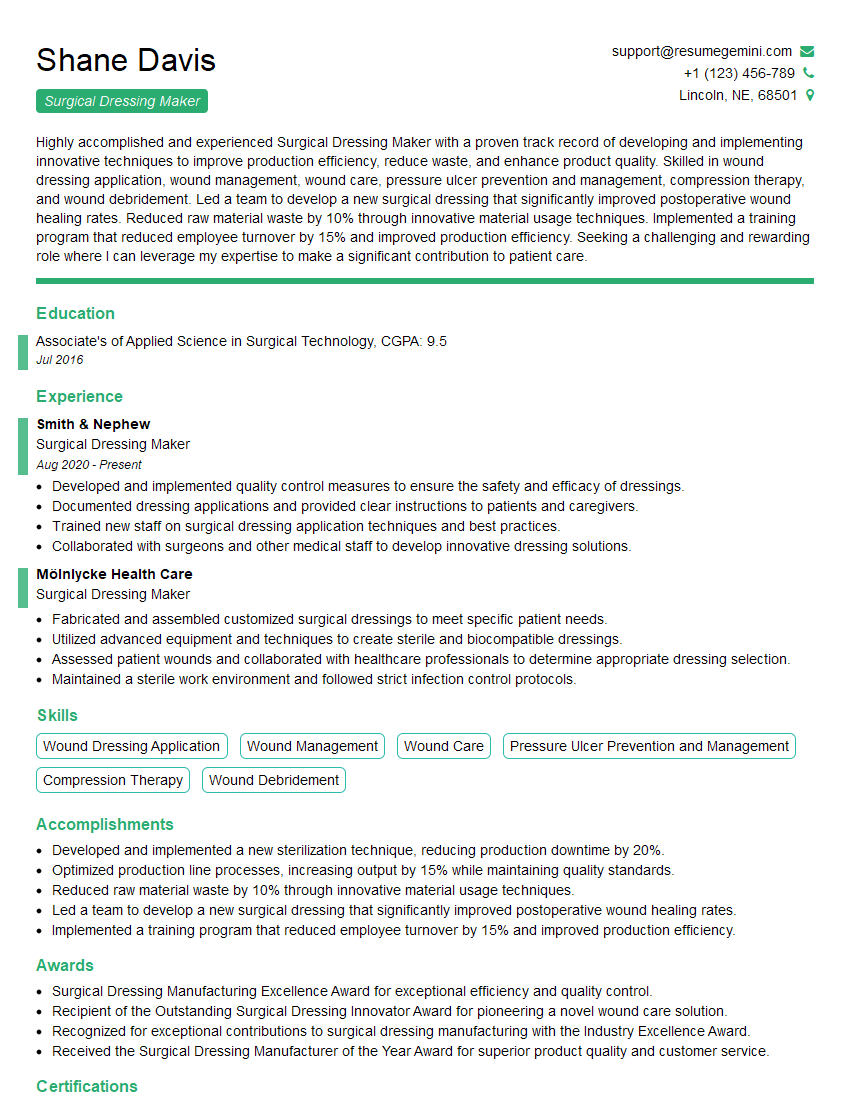

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Surgical Dressing Maker

1. How do you determine the appropriate material and thickness for a surgical dressing?

To determine the appropriate material and thickness for a surgical dressing, I consider several factors:

- Wound type and severity: Different wounds require specific materials and thicknesses to promote healing and prevent infection.

- Patient’s condition: The patient’s overall health, allergies, and sensitivity to certain materials must be taken into account.

- Dressing purpose: The intended purpose of the dressing, such as absorption, protection, or wound closure, influences the choice of material and thickness.

- Manufacturer’s guidelines: I carefully review product specifications and recommendations from manufacturers to ensure proper selection and application.

2. What are the key steps involved in the production of surgical dressings?

Sterilization:

- Surgical dressings undergo rigorous sterilization processes to eliminate harmful microorganisms.

- This ensures the safety and sterility of the dressings for patient use.

Material Selection:

- The appropriate material is chosen based on wound characteristics and the desired dressing properties.

- Materials may include cotton, non-woven fabrics, or specialized polymers.

Fabrication:

- Dressings are fabricated using specialized machinery and techniques.

- This may include cutting, shaping, and assembling the materials.

3. How do you ensure the quality and safety of surgical dressings?

I ensure the quality and safety of surgical dressings through several measures:

- Adherence to Standards: I strictly adhere to industry standards and regulatory requirements.

- Quality Control Inspections: Regular inspections are conducted to check for defects and contamination.

- Sterilization Validation: The effectiveness of sterilization processes is regularly validated through testing.

- Supplier Management: I work closely with suppliers to ensure the quality of raw materials used in dressing production.

4. What types of adhesives are used in surgical dressings and how do you choose the appropriate one?

Surgical dressings typically use different types of adhesives to secure them to the wound site:

- Acrylic Adhesives: These are commonly used due to their strong adhesion, hypoallergenic properties, and ability to conform to irregular surfaces.

- Silicone Adhesives: Known for their gentle and non-irritating nature, silicone adhesives are ideal for delicate skin and long-term applications.

- Hydrogel Adhesives: These adhesives absorb wound exudate, creating a moist environment that promotes healing.

- The choice of adhesive depends on:

- Wound type and location.

- Patient’s skin sensitivity.

- Required dressing duration.

5. How do you handle and store surgical dressings to maintain their sterility?

To maintain the sterility of surgical dressings, I follow strict protocols:

- Packaging Integrity: Dressings are stored in sealed, sterile packaging to prevent contamination.

- Designated Storage Area: Dressings are kept in a designated, temperature-controlled environment away from potential contaminants.

- First-In, First-Out (FIFO) Rotation: Dressings are used in the order they arrive to prevent expiration.

- Staff Training: Proper handling and storage techniques are communicated to all staff involved in dressing management.

6. What are the different types of surgical dressings and their specific uses?

There are various types of surgical dressings, each designed for specific purposes:

- Adhesive Dressings: Used to cover and protect wounds, they come in various sizes and shapes with different adhesives.

- Gauze Dressings: Highly absorbent, used for packing wounds or absorbing exudate.

- Foam Dressings: Provide cushioning and absorb exudate, often used for pressure ulcers or surgical incisions.

- Hydrocolloid Dressings: Form a gel-like substance that creates a moist wound environment, promoting healing.

- Alginate Dressings: Made from seaweed, highly absorbent and used for heavily exudating wounds.

7. How do you assess a wound to determine the most appropriate dressing choice?

Assessing a wound involves:

- Wound Size and Depth: Determining the extent of the wound helps guide dressing selection.

- Exudate Level: The amount of fluid produced by the wound indicates the absorbency required in the dressing.

- Wound Bed Appearance: Healthy granulation tissue or signs of infection influence dressing selection.

- Patient Factors: Allergies, skin sensitivity, and mobility can affect dressing choice.

8. What are the potential complications associated with surgical dressings and how can they be prevented?

Potential complications include:

- Infection: Ensuring sterility and proper wound care techniques can minimize infection risk.

- Allergic Reactions: Using hypoallergenic dressings and assessing patient allergies can prevent reactions.

- Maceration: Dressings should be changed regularly to avoid moisture buildup and skin breakdown.

- Pressure Ulcers: Proper dressing selection and application can prevent pressure points and skin damage.

9. How do you stay up-to-date with advancements in surgical dressing technology?

To stay current, I:

- Attend Industry Conferences: Participate in conferences and workshops to learn about new technologies and advancements.

- Read Professional Journals: Regularly review medical literature and research articles to stay informed.

- Collaborate with Healthcare Professionals: Engage with surgeons, nurses, and other healthcare professionals to gain insights into evolving needs and dressing performance.

- Product Demonstrations: Attend product demonstrations and trial new dressings to evaluate their effectiveness firsthand.

10. How do you prioritize tasks and manage multiple projects simultaneously in a busy production environment?

In a busy production environment, I prioritize tasks and manage multiple projects effectively through:

- Prioritization Matrix: I use a prioritization matrix to categorize tasks based on urgency and importance.

- Project Management Tools: I utilize project management software or tools to track progress, set deadlines, and allocate resources.

- Effective Communication: I communicate regularly with team members and supervisors to ensure clear expectations and avoid duplication of efforts.

- Time Management Techniques: I employ time management techniques such as time blocking and the Pomodoro Technique to maximize productivity and minimize distractions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Surgical Dressing Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Surgical Dressing Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Surgical Dressing Makers are responsible for manufacturing and maintaining surgical dressings, which are used to protect wounds and promote healing. They work in a clean and sterile environment, following strict quality control procedures.

1. Manufacturing Surgical Dressings

The primary responsibility of Surgical Dressing Makers is to manufacture surgical dressings. This involves:

- Selecting and cutting materials, such as gauze, cotton, and adhesive

- Assembling dressings according to prescribed specifications

- Packaging and labeling dressings for distribution

2. Maintaining Quality Control

Surgical Dressing Makers are responsible for maintaining quality control throughout the manufacturing process. This involves:

- Inspecting raw materials for defects

- Monitoring production processes to ensure compliance with standards

- Testing finished products to verify performance and safety

3. Research and Development

Surgical Dressing Makers may also be involved in research and development activities. This involves:

- Evaluating new materials and technologies

- Developing new or improved surgical dressings

- Conducting clinical trials to test the efficacy and safety of new products

4. Customer Service

Surgical Dressing Makers may also provide customer service. This involves:

- Answering customer inquiries about products and services

- Providing technical support to customers

- Resolving customer complaints

Interview Tips

Preparing for an interview for a Surgical Dressing Maker position requires a combination of technical knowledge and soft skills. Here are some tips to enhance your interview performance.

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and mission. Explore their website and social media pages to gain insights into their culture and values. Review the job description thoroughly to understand the specific requirements of the position.

2. Highlight Your Technical Skills

During the interview, emphasize your technical expertise in surgical dressing manufacturing. Describe your experience in selecting and cutting materials, assembling dressings, and maintaining quality control. Share examples of your involvement in research and development projects.

3. Showcase Your Attention to Detail

Surgical Dressing Makers must possess meticulous attention to detail. During the interview, provide examples of your ability to follow instructions, identify defects, and ensure that products meet specifications.

4. Demonstrate Your Problem-Solving Abilities

Surgical Dressing Makers often encounter unexpected challenges. In the interview, highlight your problem-solving skills by describing situations where you identified and resolved issues effectively.

5. Emphasize Your Commitment to Quality

Surgical dressings play a critical role in patient care. Express your passion for delivering high-quality products and maintaining rigorous quality standards throughout the manufacturing process.

6. Prepare Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare questions about the company’s growth plans, innovation initiatives, or anything that demonstrates your genuine curiosity and enthusiasm.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Surgical Dressing Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Surgical Dressing Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.