Feeling lost in a sea of interview questions? Landed that dream interview for Tube Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tube Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

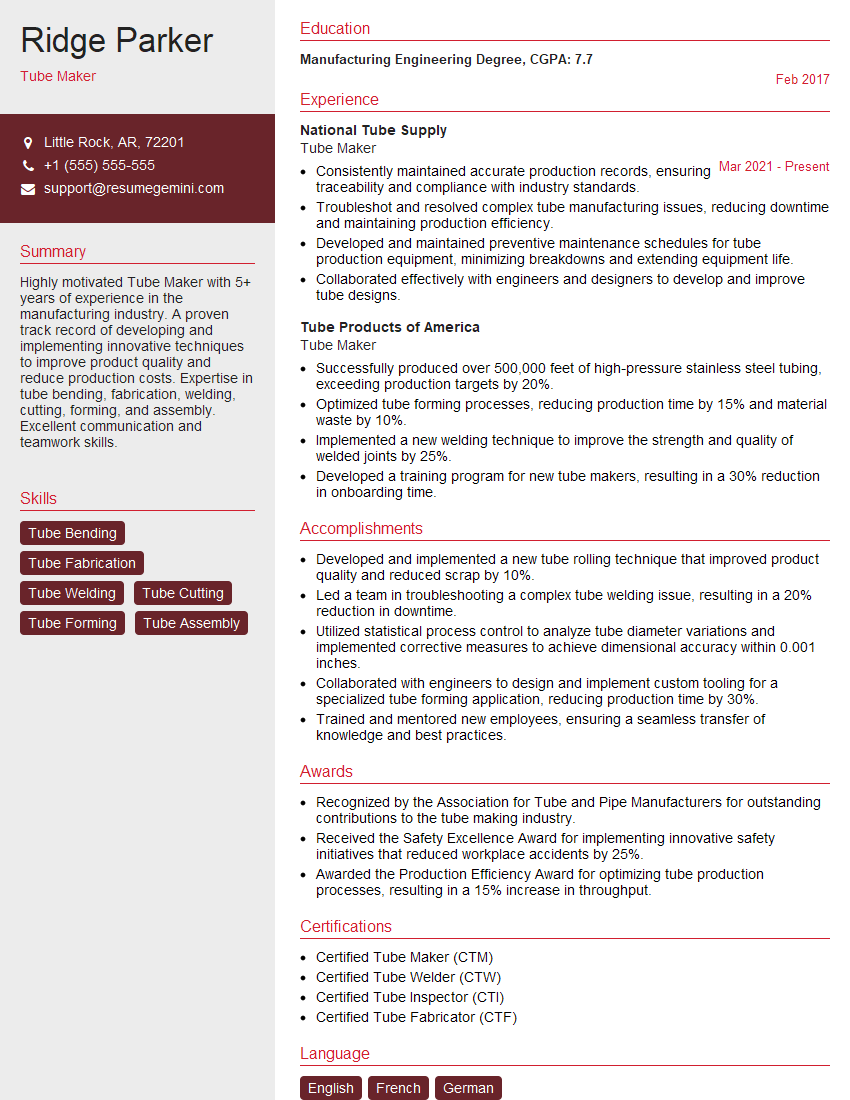

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Maker

1. What are the different tube materials used in manufacturing and their applications?

Tube materials vary in properties and applications. Here are some common types:

- Steel: Strong and durable, used in structural applications, automotive parts, and pressure vessels.

- Copper: Excellent electrical and thermal conductivity, commonly used in electrical wiring, plumbing, and heat exchangers.

- Aluminum: Lightweight and corrosion-resistant, employed in aerospace, automotive, and construction industries.

- Stainless Steel: Corrosion-resistant and heat-resistant, used in food processing, chemical processing, and medical equipment.

- Plastic: Lightweight, flexible, and chemically resistant, used in fluid transportation, packaging, and electrical insulation.

2. What is the process of tube manufacturing?

Raw Material Preparation

- Selecting and preparing raw materials (metal, plastic, etc.)

- Cutting and forming the raw material into desired shapes

Tube Forming

- Using various methods (e.g., extrusion, rolling, drawing) to create tubular shapes

- Controlling dimensions, tolerances, and surface finish

Finishing and Inspection

- Applying heat treatments, coatings, or surface treatments

- Performing quality control checks to ensure conformity

3. What are the key factors to consider when selecting tube materials?

- Application: Intended use and operating conditions

- Mechanical properties: Strength, hardness, ductility

- Corrosion resistance: Exposure to chemicals, moisture, or other corrosive environments

- Cost: Material cost and manufacturing expenses

- Availability: Ease of sourcing and lead times

4. Explain the different methods of tube bending and their suitability for various applications.

- Rotary Draw Bending: Precise and efficient for bending thin and medium-wall tubes, suitable for small radii.

- Mandrel Bending: Uses a mandrel to support the inside of the tube during bending, preventing collapse and maintaining cross-sectional shape.

- Roll Bending: Suitable for bending large-diameter tubes, provides a high level of accuracy and repeatability.

- Compression Bending: Used for bending thicker tubes, involves applying pressure to the outside of the tube.

5. How do you ensure the quality of tubes produced?

- Raw Material Inspection: Verifying material composition, dimensions, and surface quality.

- In-Process Inspection: Monitoring dimensions, tolerances, and surface finish during manufacturing.

- Non-Destructive Testing: Using techniques like ultrasonic or eddy current testing to detect internal defects or flaws.

- Final Inspection: Comprehensive examination of all aspects of the tube, including dimensional accuracy, surface quality, and performance.

6. Discuss the importance of lubrication in tube manufacturing and its impact on production efficiency.

- Reduces Friction: Lubrication minimizes friction between the tube and forming tools, preventing wear and tear on equipment.

- Improves Surface Finish: Lubrication helps achieve smoother and more consistent surface finishes on the tubes.

- Enhances Tool Life: Proper lubrication extends the lifespan of forming tools, reducing maintenance and replacement costs.

- Increases Production Efficiency: Reduced friction and improved tool life lead to faster production speeds and higher efficiency.

7. What is the role of annealing in tube manufacturing?

- Stress Relief: Annealing removes internal stresses induced during forming or cold working.

- Softening: It softens the tube material, improving its ductility and formability.

- Microstructure Refinement: Annealing alters the microstructure of the material, improving its mechanical properties.

- Enhanced Machinability: Annealed tubes are easier to machine, reducing tool wear and improving machining efficiency.

8. Explain the different types of tube welding processes and their advantages and disadvantages.

- TIG Welding: Uses a tungsten electrode and a shielding gas, providing high-quality welds with minimal distortion.

- MIG Welding: Employs a continuously fed wire electrode, offering high speed and deposition rates.

- Plasma Arc Welding: Utilizes a plasma arc to create concentrated heat, suitable for welding thin and non-ferrous materials.

- Laser Welding: Uses a focused laser beam to weld tubes with precision and high strength.

9. Describe the factors that affect the accuracy and repeatability of a tube cutting process.

- Equipment Precision: Accuracy of the cutting machinery and tooling.

- Material Properties: Hardness, thickness, and uniformity of the tube material.

- Cutting Parameters: Speed, feed, and depth of cut.

- Operator Skill: Experience and training of the operator.

- Environmental Factors: Temperature, humidity, and vibration.

10. How do you troubleshoot common defects encountered during tube manufacturing?

- Dimensional Errors: Adjust forming parameters, check tooling, and ensure proper temperature control.

- Surface Defects: Identify the cause (e.g., improper lubrication, tool wear), and implement corrective actions.

- Welding Defects: Inspect welding parameters, verify joint preparation, and ensure proper shielding gas use.

- Material Defects: Conduct material testing, trace the source of the defects, and implement quality control measures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tube Makers are responsible for overseeing the production of tubes, typically metallic, through various processes such as welding, bending, and shaping. They ensure the quality and specifications of the tubes meet the required standards.

1. Tube Production

Oversee the entire production process of tubes, ensuring the quality and efficiency of the operation.

- Plan and schedule production activities, optimizing resource utilization, including manpower, machinery, and materials.

- Monitor production lines, identifying and resolving bottlenecks and inefficiencies.

2. Quality Control

Implement and maintain quality control procedures to ensure the tubes meet specifications and standards.

- Conduct regular inspections of the tubes, using precision measuring instruments and gauges.

- Identify and rectify any deviations from the desired specifications, ensuring compliance with quality standards.

3. Machine Operation

Operate and maintain tube-making machinery, ensuring efficient and safe operation.

- Follow established operating procedures, adhering to safety guidelines and minimizing downtime.

- Troubleshoot and resolve machine malfunctions, performing necessary repairs and adjustments.

4. Continuous Improvement

Identify areas for improvement in production processes and implement solutions to enhance efficiency and quality.

- Analyze production data, identifying trends and areas for optimization.

- Collaborate with other departments to implement process improvements, such as lean manufacturing techniques.

Interview Tips

Preparing for a job interview can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and Position:

Demonstrate your interest in the role and the company by researching their website, industry news, and social media presence. This will help you understand their values, mission, and specific requirements for the Tube Maker position.

- Tailor your resume and cover letter to highlight your skills and experience relevant to the job responsibilities.

Practice Commonly Asked Questions:

Prepare for common interview questions related to your technical expertise, problem-solving abilities, and experience in the field. Practice answering these questions clearly and concisely, providing specific examples to showcase your skills.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing context and quantifiable results.

Highlight Your Technical Skills:

Emphasize your proficiency in tube-making techniques, machine operation, and quality control procedures. Quantify your experience with specific tools, equipment, and software.

- Be prepared to discuss your understanding of industry standards and certifications related to tube manufacturing.

Demonstrate Your Problem-Solving Abilities:

Share examples of how you have successfully identified and resolved production issues, implemented process improvements, or ensured compliance with quality standards.

- Highlight your analytical and critical thinking skills, as well as your ability to work independently and as part of a team.

Convey Your Passion for Continuous Improvement:

Express your commitment to continuous learning and improvement in the field of tube making. Discuss your willingness to adopt new technologies and methodologies to enhance production efficiency and quality.

- Share examples of how you have actively sought opportunities for professional development or taken initiatives to improve your knowledge and skills.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tube Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tube Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.