Feeling lost in a sea of interview questions? Landed that dream interview for Tumbler Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tumbler Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

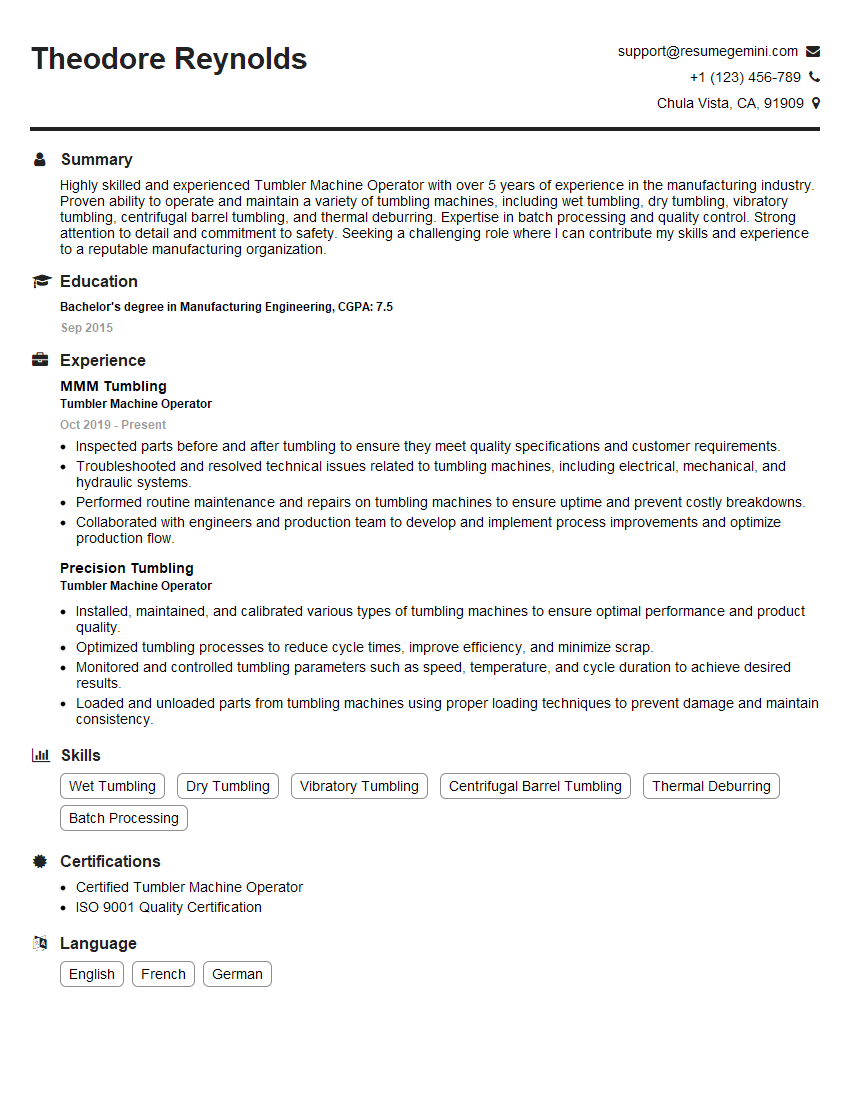

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tumbler Machine Operator

1. Describe the process of loading and unloading parts into a tumbler machine?

To load parts into a tumbler machine, I first inspect them to ensure they are free of any contaminants or damage. I then place the parts into the tumbler machine, making sure they are evenly distributed and not touching each other. I close the lid of the tumbler machine and secure it tightly. To unload the parts, I stop the machine and open the lid. I remove the parts from the machine and place them in a designated area.

2. What are the different types of tumbling media and their applications?

Abrasive Media

- Used for deburring, grinding, and polishing

- Examples: Ceramic, plastic, or metal beads

Non-Abrasive Media

- Used for burnishing, smoothing, and cleaning

- Examples: Wood chips, corn cob, or walnut shells

3. How do you determine the correct tumbling speed and time for a specific application?

- Consider the type of parts being tumbled

- Determine the desired finish

- Refer to manufacturer’s recommendations

- Experiment with different speeds and times to optimize results

4. What are the common troubleshooting steps for tumbler machine malfunctions?

- Check for power supply issues

- Inspect the tumbler barrel and media for damage or wear

- Verify the correct tumbling speed and time settings

- Clean the machine and media regularly

- Contact the manufacturer for technical support if necessary

5. Describe the safety precautions that should be taken when operating a tumbler machine?

- Wear appropriate personal protective equipment (PPE)

- Keep loose clothing and jewelry away from moving parts

- Never open the lid of the machine while it is running

- Ensure proper ventilation to avoid exposure to dust or fumes

- Follow manufacturer’s safety guidelines and instructions

6. How do you maintain and calibrate a tumbler machine?

- Inspect the machine regularly for any wear or damage

- Clean and lubricate moving parts as per the manufacturer’s instructions

- Calibrate the machine using a tachometer or other measuring device

- Keep a maintenance log to track inspections, repairs, and calibrations

7. What are the key quality control measures for tumbler machine operations?

- Inspect the parts before and after tumbling for any defects or damage

- Monitor the tumbling process to ensure the correct speed and time are being used

- Use quality control tools such as gauges or calipers to verify the desired finish

- Maintain documentation on all quality control checks and inspections

8. How do you handle situations where the desired finish is not achieved?

- Identify the cause of the problem (e.g., incorrect tumbling media, speed, or time)

- Make adjustments to the process parameters

- Experiment with different tumbling media or compounds

- Consult with the manufacturer or a technical expert for assistance

9. Describe your experience in using different types of tumbler machines?

- Horizontal barrel tumblers

- Vibratory tumblers

- Centrifugal barrel tumblers

10. How do you stay updated on the latest advancements in tumbler machine technology?

- Attend industry conferences and workshops

- Read technical journals and publications

- Consult with equipment manufacturers

- Network with other professionals in the field

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tumbler Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tumbler Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tumbler Machine Operator is accountable for operating a tumbling machine to clean or deburr various parts and components. They must ensure that the machine is functioning properly and that the work pieces are cleaned or deburred to the required specifications.

1. Machine Operation

Operate and monitor the tumbling machine. Load and unload work pieces. Set and adjust machine speed, duration, and temperature.

2. Quality Control

Inspect work pieces before and after processing to ensure proper cleaning or deburring. Identify and resolve any defects or issues with the machine or work pieces.

3. Maintenance

Perform routine maintenance on the tumbling machine. Clean and lubricate components. Repair minor issues or report major issues to maintenance personnel.

4. Material Handling

Handle and transport work pieces and other materials safely and efficiently. Use appropriate equipment and procedures to prevent accidents or damage.

Interview Tips

To prepare for an interview for a Tumbler Machine Operator position, consider the following tips and hacks.

1. Research the Company and Position

Familiarize yourself with the company’s website, industry news, and the specific role you are applying for. This will help you understand their business, culture, and the key responsibilities of the position.

2. Highlight Your Relevant Skills and Experience

Emphasize your skills in operating and maintaining tumbling machines, your attention to detail and quality control, and your ability to work independently and as part of a team.

3. Prepare Examples of Your Work

If possible, bring examples of your work, such as detailed descriptions or case studies, to demonstrate your abilities and experience with tumbling machines.

4. Practice Common Interview Questions

Anticipate common interview questions, such as “Tell me about your experience with tumbling machines” or “How do you ensure quality control in your work?” Practice your answers to these questions to present yourself confidently and clearly.

5. Dress Professionally and Arrive on Time

Make a good impression by dressing professionally and arriving at the interview on time. This demonstrates your respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tumbler Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!