Feeling lost in a sea of interview questions? Landed that dream interview for Valving Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Valving Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

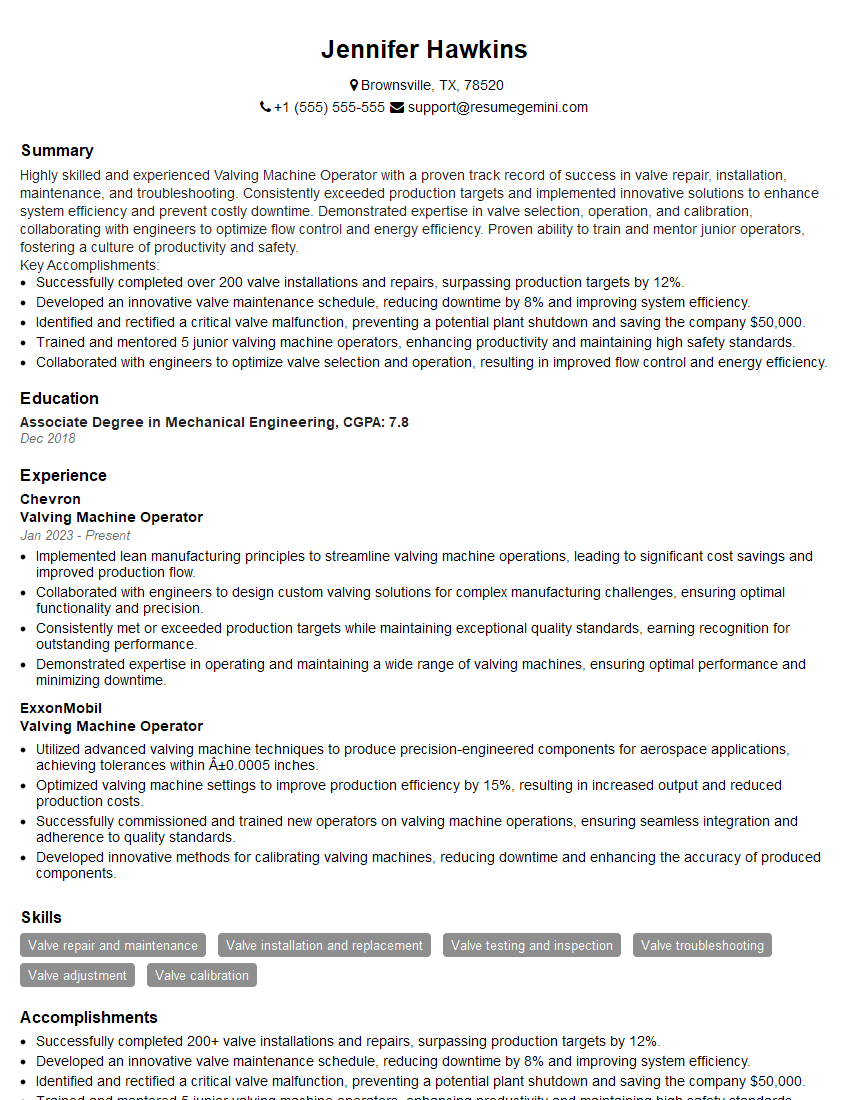

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Valving Machine Operator

1. Explain the process of setting up a valving machine?

- 1. Check the machine for any signs of damage or wear.

- 2. Mount the valve on the machine table.

- 3. Connect the air and electrical lines to the machine.

- 4. Set the machine parameters, including the speed, pressure, and cycle time.

- 5. Test the machine to ensure that it is operating properly.

2. What are the different types of valving machines?

subheading of the answer

- 1. Rotary valving machines

- 2. Linear valving machines

- 3. Progressive valving machines

subheading of the answer

- 1. Rotary valving machines are used for high-volume production of small parts.

- 2. Linear valving machines are used for low-volume production of large parts.

- 3. Progressive valving machines are used for medium-volume production of parts that require multiple operations.

3. What are the key factors to consider when selecting a valving machine?

- 1. The type of parts that will be produced.

- 2. The production volume.

- 3. The budget.

- 4. The available space.

- 5. The machine’s features.

4. What are the most common valving machine problems?

- 1. Valve clogs

- 2. Air leaks

- 3. Electrical problems

- 4. Mechanical problems

5. How do you troubleshoot a valving machine problem?

- 1. Identify the symptoms of the problem.

- 2. Check the machine for any signs of damage or wear.

- 3. Check the air and electrical connections.

- 4. Check the machine parameters.

- 5. Test the machine to confirm the problem.

6. What are the safety precautions that must be taken when operating a valving machine?

- 1. Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- 2. Keep the machine area clean and free of debris.

- 3. Do not operate the machine if it is damaged or not functioning properly.

- 4. Be aware of the machine’s moving parts and keep your hands and body out of the way.

- 5. Follow all safety instructions provided by the machine manufacturer.

7. What are the maintenance procedures that must be performed on a valving machine?

- 1. Clean the machine regularly.

- 2. Lubricate the machine’s moving parts.

- 3. Inspect the machine for any signs of damage or wear.

- 4. Calibrate the machine regularly.

- 5. Follow all maintenance instructions provided by the machine manufacturer.

8. What are the benefits of using a valving machine?

- 1. Increased production speed

- 2. Improved product quality

- 3. Reduced labor costs

- 4. Increased safety

- 5. Reduced environmental impact

9. What are the challenges of using a valving machine?

- 1. High cost

- 2. Complex setup

- 3. Requires skilled operators

- 4. Potential for downtime

- 5. Safety concerns

10. What are the future trends in valving machine technology?

- 1. Increased automation

- 2. Improved precision

- 3. Reduced cost

- 4. Increased safety

- 5. Increased environmental sustainability

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Valving Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Valving Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Valving Machine Operator is responsible for the operation and maintenance of valving machines in a manufacturing environment. The primary objective of this role is to ensure the efficient and safe production of valves, adhering to established quality standards and specifications.

1. Machine Operation

Setting up and operating valving machines, ensuring precision and accuracy in valve production.

- Loading and unloading raw materials and finished products from the machine.

- Monitoring machine performance, making necessary adjustments to optimize production.

2. Quality Control

Inspecting valves for defects and adhering to established quality standards.

- Conducting dimensional checks, visual inspections, and pressure testing.

- Maintaining accurate records of quality control data.

3. Maintenance and Troubleshooting

Performing routine maintenance and troubleshooting on valving machines.

- Cleaning and lubricating machine parts.

- Identifying and resolving machine malfunctions.

4. Safety Compliance

Observing safety procedures and regulations in the work environment.

- Wearing appropriate personal protective equipment (PPE).

- Following established safety protocols for machine operation and maintenance.

Interview Tips

Preparing for an interview as a Valving Machine Operator requires a combination of technical knowledge and presentation skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company, its products, and the specific position you are applying for. This will demonstrate your interest and enthusiasm for the opportunity.

- Visit the company website and social media pages.

- Read industry news and articles related to valving technology.

2. Highlight Your Technical Skills

Emphasize your proficiency in valving machine operation, quality control, and maintenance. Quantify your accomplishments with specific examples.

- Provide details about the types of valving machines you have operated.

- Describe your experience in quality control procedures and troubleshooting.

3. Demonstrate Your Safety Awareness

Highlight your commitment to safety in the workplace. Explain your understanding of safety protocols and your experience in adhering to them.

- Discuss your knowledge of OSHA regulations and industry best practices.

- Share examples of how you have promoted safety in previous work environments.

4. Prepare for Common Interview Questions

Review common interview questions related to the role and prepare thoughtful answers. Practice your responses to questions about your experience, skills, and motivation.

- Describe your experience in operating and maintaining valving machines.

- How do you ensure the quality of valves produced on the machine?

Next Step:

Now that you’re armed with the knowledge of Valving Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Valving Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini