Are you gearing up for a career in Varnishing Unit Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Varnishing Unit Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

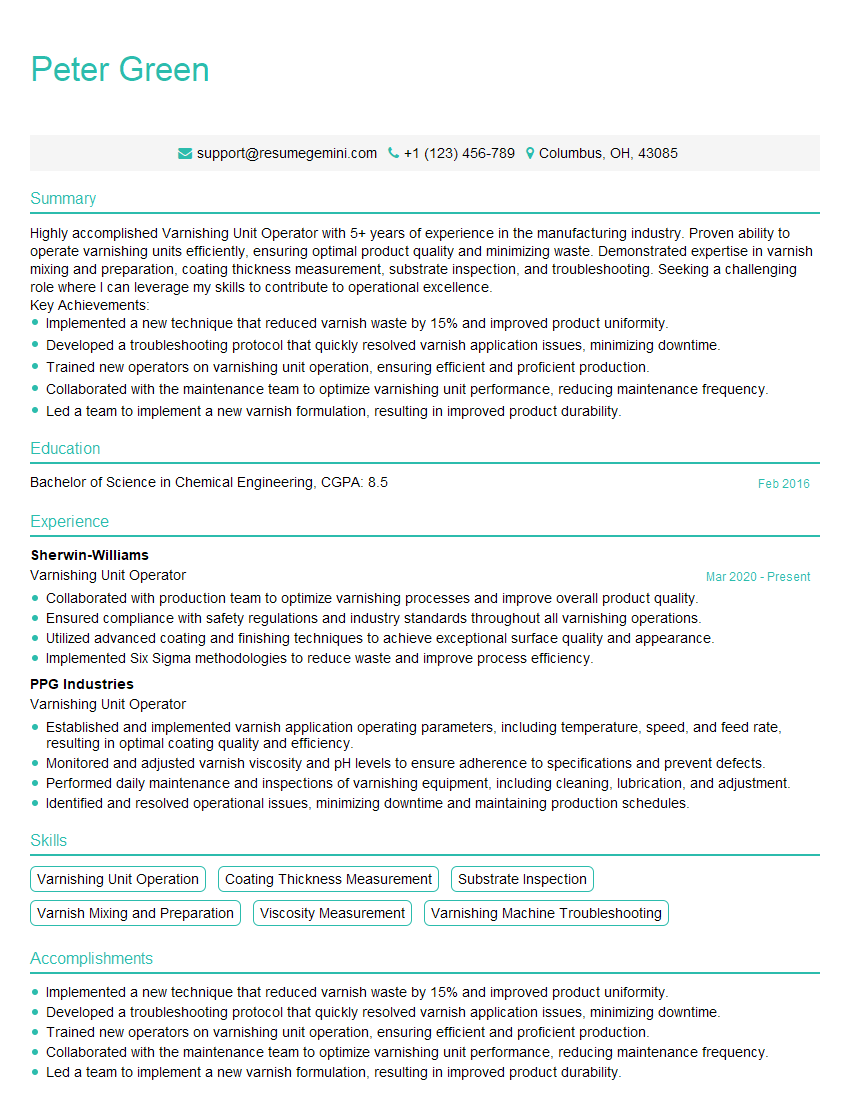

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Varnishing Unit Operator

1. Explain the process of operating a varnishing unit?

The process of operating a varnishing unit involves several key steps to ensure proper application and finishing of the varnish on the surface of the material:

- Preparation: Before operating the varnishing unit, it is essential to prepare the machine by setting up the required parameters such as roller speed, varnish viscosity, and temperature.

- Material loading: The material that needs to be varnished is loaded onto the conveyor system of the unit, ensuring proper alignment and positioning to achieve uniform varnish application.

- Application: The varnish is applied to the material as it passes through the varnishing unit. The application can be controlled by adjusting the roller speed, varnish viscosity, and temperature to achieve the desired thickness and finish.

- Drying: After the varnish is applied, the material enters the drying zone, where it is exposed to heat or UV light to facilitate the drying process. The drying time and temperature depend on the type of varnish and the desired level of dryness.

- Unloading: Once the material is dried, it is unloaded from the conveyor system, completing the varnishing process.

2. What are the different types of varnishes used in a varnishing unit?

Solvent-based varnishes

- These varnishes contain organic solvents that evaporate during the drying process, leaving behind a protective film on the surface.

- They are commonly used in industrial applications due to their fast drying time and durability.

Water-based varnishes

- These varnishes are formulated with water as the main solvent, making them more environmentally friendly.

- They offer good adhesion and leveling properties, but may require longer drying times compared to solvent-based varnishes.

UV-curable varnishes

- These varnishes are cured using ultraviolet light, providing instant drying and high scratch resistance.

- They are often used in high-speed applications and for specialized finishes.

3. How do you troubleshoot common problems that occur in a varnishing unit?

- Streaking or uneven varnish application: This can be caused by improper roller adjustment, incorrect varnish viscosity, or contamination of the varnish.

- Bubbles or pinholes in the varnish film: This can be caused by trapped air during application or insufficient drying time.

- Varnish drying too slowly: This can be caused by low drying temperature, poor ventilation, or incorrect varnish formulation.

- Varnish peeling or flaking: This can be caused by poor adhesion between the varnish and the substrate, or improper surface preparation.

4. What are the safety precautions that need to be taken when operating a varnishing unit?

- Wear appropriate personal protective equipment (PPE): This includes gloves, eye protection, and a respirator if necessary.

- Handle varnishes properly: Varnishes can be flammable or toxic, so proper storage, handling, and disposal procedures should be followed.

- Maintain a clean work area: Regularly clean the varnishing unit and surrounding area to prevent buildup of varnish or solvents.

- Be aware of potential hazards: Identify potential hazards such as moving machinery, electrical components, or hot surfaces, and take appropriate precautions to avoid accidents.

5. What maintenance tasks are required for a varnishing unit?

- Regular cleaning: Clean the rollers, tanks, and other components to prevent varnish buildup and contamination.

- Roller adjustment: Adjust the rollers to ensure proper varnish application and avoid streaking.

- Varnish viscosity checks: Monitor the varnish viscosity and adjust it as needed to achieve the desired application thickness.

- Preventive maintenance: Follow the manufacturer’s recommended maintenance schedule to prevent breakdowns and extend the lifespan of the unit.

6. How do you ensure the quality of the varnished surface?

- Visual inspection: Regularly inspect the varnished surface for defects such as streaks, bubbles, or unevenness.

- Gloss measurement: Use a gloss meter to measure the gloss level of the varnished surface and ensure it meets the desired specifications.

- Adhesion testing: Conduct adhesion tests to ensure that the varnish adheres properly to the substrate.

- Durability testing: Perform durability tests to evaluate the resistance of the varnished surface to factors such as abrasion, chemicals, and UV light.

7. What is the difference between roller coating and curtain coating?

Roller coating

- Involves transferring varnish onto the material using rollers.

- Suitable for applying thick, even coatings.

- Can be used with various types of varnishes.

Curtain coating

- Involves flowing varnish over the material like a curtain.

- Suitable for applying thin, uniform coatings.

- Typically used with water-based or low-viscosity varnishes.

8. What are the key factors that affect the varnish drying time?

- Varnish formulation: The type and composition of the varnish can influence its drying time.

- Varnish thickness: Thicker varnish layers generally take longer to dry.

- Drying temperature: Higher temperatures accelerate the drying process.

- Airflow and ventilation: Good ventilation helps remove solvents and promotes faster drying.

- Substrate material: The porosity and moisture content of the substrate can affect drying time.

9. How do you calculate the amount of varnish required for a specific job?

- Determine the surface area to be varnished: Measure the length and width of the material to calculate the surface area.

- Estimate the varnish coverage rate: Refer to the varnish manufacturer’s specifications for the coverage rate, which indicates the area that can be covered per unit volume of varnish.

- Calculate the varnish quantity: Multiply the surface area by the inverse of the coverage rate to determine the required volume of varnish.

10. What is your experience in working with different types of materials in a varnishing unit?

In my previous role as a Varnishing Unit Operator, I have had hands-on experience in applying varnishes to various types of materials, including:

- Wood: Varnished wood surfaces to enhance their appearance, durability, and resistance to moisture and wear.

- Metal: Applied varnishes to metal surfaces to protect them from corrosion and improve their aesthetic appeal.

- Plastic: Varnished plastic components to enhance their scratch resistance, UV stability, and overall durability.

- Paper and cardboard: Used varnishing techniques to improve the printability, moisture resistance, and appearance of paper and cardboard products.

- Textiles: Applied varnishes to textiles to enhance their colorfastness, water repellency, and resistance to fading.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Varnishing Unit Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Varnishing Unit Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Varnishing Unit Operator is responsible for flawlessly operating all machinery used in the varnishing process. The successful candidate will proactively maintain a clean and organized work area, adhere to all established safety procedures to prevent accidents or injuries, and efficiently complete all assigned tasks to meet production goals.

1. Operating Machinery

The Varnishing Unit Operator is required to have a complete understanding of the various machines used in the varnishing process, including the laminating machine, coater, and oven, to ensure accurate and efficient operation. They are responsible for meticulously monitoring all machine parameters, making timely adjustments as needed to ensure optimal performance and prevent defects or rejects.

- Operate varnishing machines, including laminators, coaters, and ovens, in accordance with established procedures.

- Monitor machine settings and make adjustments as necessary to maintain optimal performance and prevent defects.

2. Maintaining Equipment

The Operator is responsible for performing routine maintenance and cleaning of all varnishing equipment, including daily inspections, lubrication, and filter changes. They are also required to identify and report any issues or malfunctions to ensure that all equipment is operating at peak efficiency.

- Conduct regular maintenance and cleaning of varnishing equipment, including cleaning rollers, inspecting parts, and replacing filters.

- Identify and report any equipment malfunctions or issues to ensure timely repairs and prevent breakdowns.

3. Quality Control

The Varnishing Unit Operator plays a crucial role in maintaining product quality by thoroughly inspecting all finished products to identify and eliminate any defects. They are also responsible for following strict quality control procedures to ensure that all products meet established specifications and customer requirements.

- Inspect finished products for defects and ensure that they meet quality standards.

- Follow established quality control procedures to maintain product consistency and customer satisfaction.

4. Safety and Compliance

The Varnishing Unit Operator is responsible for maintaining a safe and compliant work environment by strictly adhering to all established safety protocols. They are required to wear appropriate personal protective equipment (PPE), follow lockout/tagout procedures, and report any potential hazards or unsafe conditions to prevent accidents or injuries.

- Wear appropriate personal protective equipment (PPE) and follow safety protocols to maintain a safe work environment.

- Follow lockout/tagout procedures to prevent accidents and injuries during maintenance or repairs.

Interview Tips

To successfully ace the interview for a Varnishing Unit Operator position, it is essential to:

1. Research the Company and Role

Before the interview, take the time to thoroughly research the company and the specific role. This demonstrates your genuine interest in the position and shows that you have taken the time to learn about their operations and values. Understanding the company’s industry, products, and mission will help you tailor your answers to the interviewer’s questions and highlight how your skills and experience align with their needs.

2. Highlight Relevant Skills and Experience

Carefully review the job description and identify the key responsibilities and skills required for the Varnishing Unit Operator role. In your responses, emphasize your relevant skills and experience, providing specific examples of how you have successfully performed similar tasks in previous positions. Quantify your accomplishments whenever possible to demonstrate the impact of your contributions.

3. Practice Answering Common Interview Questions

Anticipate common interview questions related to your technical habilidades, problem-solving abilities, and safety consciousness. Prepare thoughtful and concise responses that showcase your expertise and professionalism. Practice answering these questions aloud to build confidence and fluency.

4. Emphasize Safety and Attention to Detail

Highlight your commitment to safety and attention to detail in your responses. Explain how you consistently follow safety protocols and maintain a clean and organized work area. Emphasize your ability to identify and address potential hazards, ensuring the safety of yourself and your colleagues.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Demonstrate your passion for the varnishing process and your eagerness to contribute to the company’s success. Show that you are a team player and are willing to go the extra mile to meet production goals and ensure customer satisfaction.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Varnishing Unit Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.