Are you gearing up for an interview for a Wad Blanking Press Adjuster position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wad Blanking Press Adjuster and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

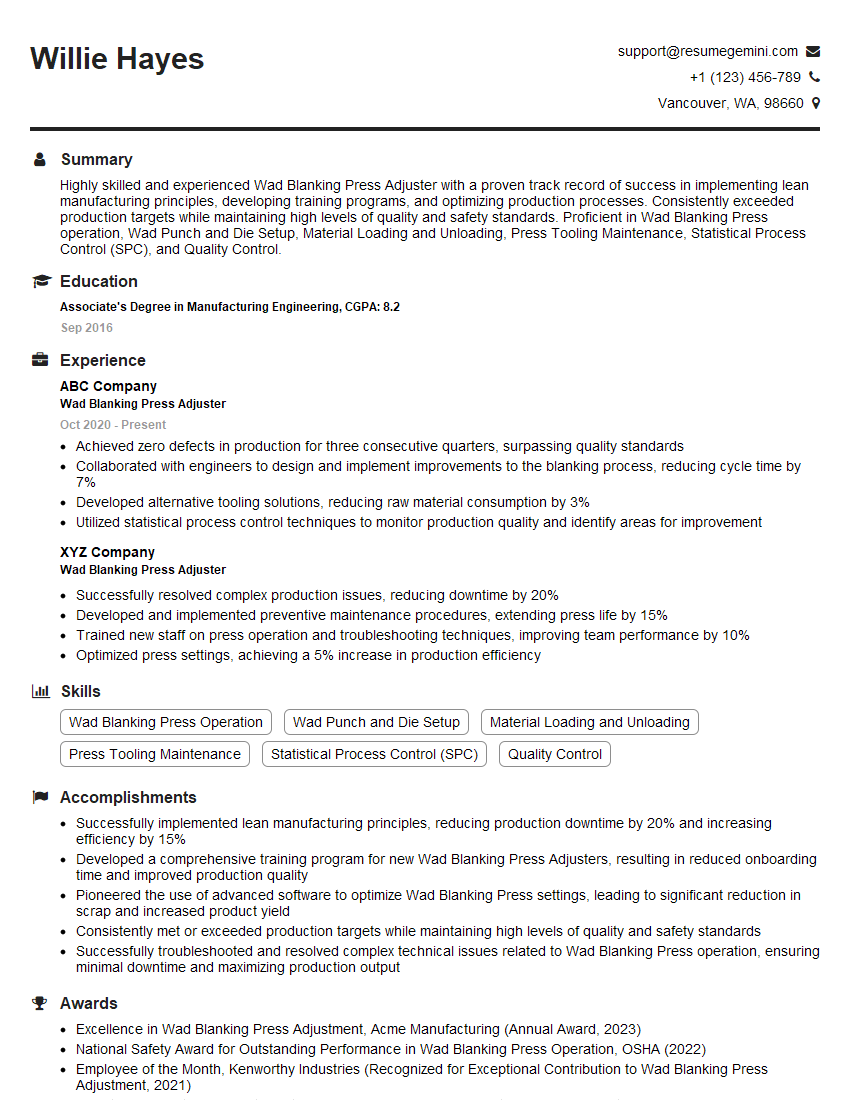

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wad Blanking Press Adjuster

1. Describe the key responsibilities of a Wad Blanking Press Adjuster?

- Set up and operate Wad Blanking Press to produce high-quality Wads.

- Adjust and maintain the press to ensure optimal performance and efficiency.

- Monitor the press during operation and make necessary adjustments to maintain production standards.

- Troubleshoot and resolve any issues or malfunctions that occur with the press

- Ensure that the press meets safety regulations and operates in a safe manner.

- Maintain a clean and organized work area, following established safety protocols.

- Work effectively as part of a team to achieve production goals.

2. How do you maintain the accuracy and precision of the Wad Blanking Press?

subheading of the answer

- Regularly calibrate and inspect the press and its components to ensure accuracy and precision.

- Use precision measuring tools and gauges to verify the dimensions and tolerances of the Wads produced.

- Monitor the press’s performance and make adjustments as needed to maintain consistent quality.

subheading of the answer

- Follow established maintenance schedules and procedures to keep the press in optimal condition.

- Identify and address potential issues before they impact production.

- Collaborate with maintenance personnel to ensure the press is properly serviced and repaired.

3. What safety precautions do you take when operating a Wad Blanking Press?

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Ensure that the press is properly grounded and all guards are in place before operating.

- Never place hands or fingers near the die area while the press is in operation.

- Be aware of potential hazards and take precautions to avoid accidents.

- Follow established safety procedures and protocols.

- Report any unsafe conditions or practices immediately.

4. What actions do you take if you encounter a problem with the Wad Blanking Press?

- Stop the press immediately and isolate the problem.

- Identify the root cause of the issue through troubleshooting.

- Make necessary adjustments or repairs to resolve the problem.

- If the issue cannot be resolved, contact maintenance personnel for assistance.

- Document the problem and the steps taken to resolve it.

5. How do you ensure the quality of the Wads produced by the Wad Blanking Press?

- Set up and operate the press according to established quality standards.

- Inspect the Wads produced at regular intervals to verify their dimensions, tolerances, and surface finish.

- Monitor the press’s performance and make adjustments as needed to maintain consistent quality.

- Identify and address any potential quality issues promptly.

6. Describe the different types of Wads that can be produced using a Wad Blanking Press?

- Fiber Wads

- Plastic Wads

- Cork Wads

- Felt Wads

- Paper Wads

7. What materials are typically used in the production of Wads?

- Paper

- Cardboard

- Plastic

- Cork

- Felt

- Rubber

8. What are the key factors that affect the quality of the Wads produced by a Wad Blanking Press?

- The condition and accuracy of the press

- The quality of the raw materials used

- The skill and experience of the operator

- The maintenance and calibration of the press

- The environmental conditions in which the press is operating

9. How do you troubleshoot common problems that can occur with a Wad Blanking Press?

- The press is not producing Wads to the correct dimensions.

- The press is not producing Wads at the desired rate.

- The press is making excessive noise or vibration.

- The press is leaking oil or other fluids.

- The press is not responding to controls.

10. What are your strengths and weaknesses as a Wad Blanking Press Adjuster?

- Strengths:

- I have a strong understanding of the principles of Wad Blanking Press operation.

- I am proficient in setting up, operating, and maintaining Wad Blanking Presses.

- I have a proven track record of producing high-quality Wads.

- I am a team player and I am always willing to help others.

- I am a quick learner and I am always looking for ways to improve my skills.

- Weaknesses:

- I am sometimes too detail-oriented, which can slow down my work.

- I am not always the most patient person, which can be a challenge when working with complex machinery.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wad Blanking Press Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wad Blanking Press Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wad Blanking Press Adjusters are entrusted with the responsibility of setting up, operating, and adjusting wad blanking presses to cut out wads from raw materials. These wads are subsequently used for a variety of purposes, including insulation, packaging, and cushioning.

1. Press Setup and Operation

Setting up the wad blanking press precisely is paramount. This involves installing the appropriate tooling and materials, adjusting press settings, and ensuring the press operates smoothly and efficiently.

- Install and adjust dies, punches, and other tooling

- Set up and calibrate press parameters, such as pressure, speed, and dwell time

- Operate the press safely and efficiently, monitoring its performance and making adjustments as needed

2. Material Handling

Proper handling of raw materials is crucial to minimize waste and ensure quality. Wad Blanking Press Adjusters must be able to load and unload materials, as well as inspect them for defects.

- Load raw materials into the press

- Unload finished wads and inspect them for quality

- Maintain proper inventory levels of raw materials and finished products

3. Maintenance and Troubleshooting

Maintaining the press in optimal condition is essential to minimize downtime and ensure productivity. Wad Blanking Press Adjusters must be able to perform basic maintenance, identify potential issues, and troubleshoot problems.

- Perform routine maintenance and cleaning

- Identify and diagnose press malfunctions

- Resolve mechanical and electrical issues

- Coordinate with maintenance personnel for major repairs

4. Quality Control

Ensuring the quality of the wads produced is a top priority. Wad Blanking Press Adjusters inspect wads for defects, such as tears, holes, or incorrect dimensions. They also conduct quality control tests to ensure the wads meet specifications.

- Inspect wads for defects and ensure they meet quality standards

- Conduct quality control tests, such as dimension checks and material testing

- Document and report quality control results

Interview Preparation Tips

A well-prepared interview can significantly increase your chances of making a positive impression and landing the job. Here are some tips to help you ace your Wad Blanking Press Adjuster interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the key responsibilities and qualifications required for the job.

- Visit the company’s website and social media pages

- Read industry publications and news articles

- Network with people who work at the company or in the industry

2. Practice Your Answers

Prepare for common interview questions by rehearsing your answers in advance. This will help you feel more confident and articulate during the interview.

- Prepare for questions about your experience, skills, and qualifications

- Practice answering behavioral questions using the STAR method (Situation, Task, Action, Result)

- Consider potential technical questions about wad blanking press operation and troubleshooting

3. Dress Professionally

First impressions matter, so dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for an office setting.

- Consider wearing a suit or business casual attire

- Choose clothes that are comfortable and allow you to move freely

- Make sure your shoes are clean and polished

4. Be Punctual

Punctuality shows respect for the interviewer’s time. Plan your travel route in advance and arrive at the interview location 5-10 minutes early.

- Calculate your travel time and leave enough time for unexpected delays

- If possible, do a practice run to the interview location the day before

- Allow yourself extra time to park and walk to the interview room

5. Be Yourself and Be Confident

The most important thing is to be yourself and be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Answer questions honestly and authentically

- Highlight your strengths and accomplishments

- Be enthusiastic about the position and the company

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wad Blanking Press Adjuster, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wad Blanking Press Adjuster positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.