Are you gearing up for a career in Wheel Truing Machine Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wheel Truing Machine Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

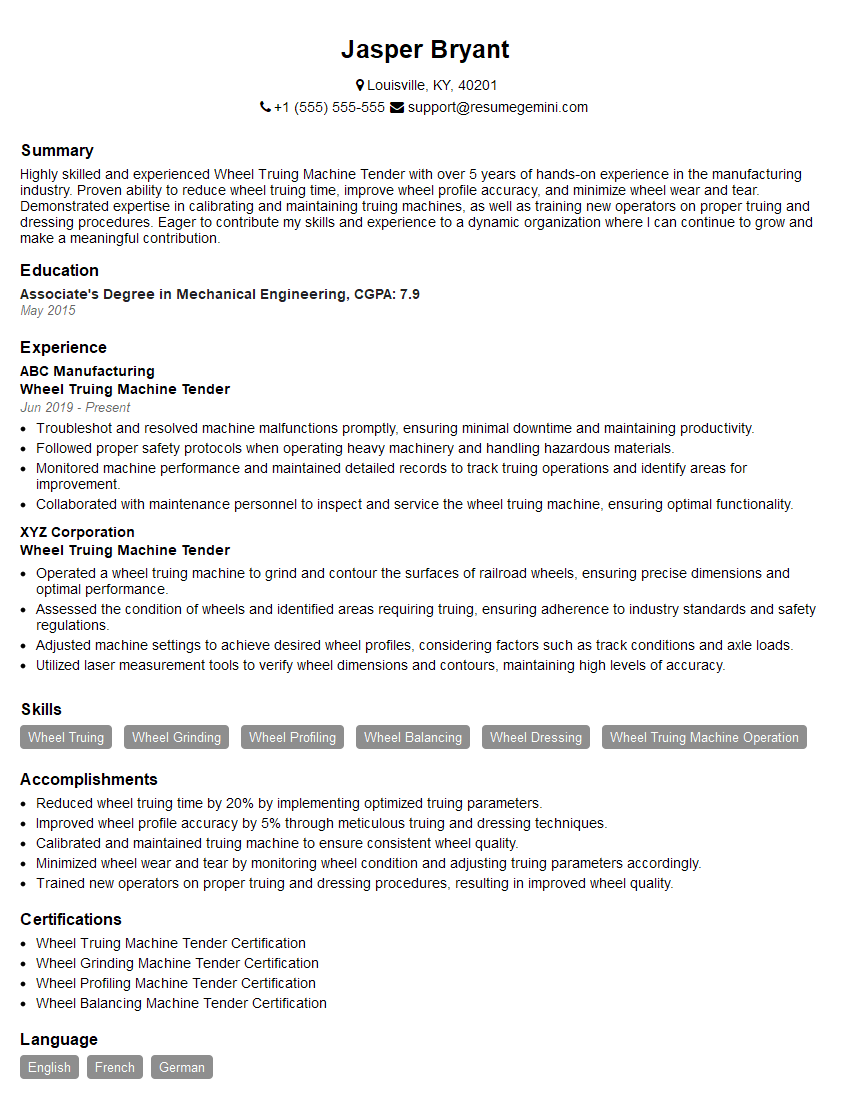

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel Truing Machine Tender

1. Explain the process of truing a wheel on a wheel truing machine?

- Mount the wheel on the truing machine and secure it using the appropriate fixtures.

- Set the cutting tool to the correct depth and angle based on the wheel’s specifications.

- Start the truing process by rotating the wheel and applying the cutting tool to the wheel’s surface.

- Monitor the truing process and make adjustments to the cutting tool or the wheel’s position as needed to ensure an accurate and smooth surface finish.

- Once the truing process is complete, remove the wheel from the machine and inspect it for accuracy and quality.

2. What are the different types of wheel truing machines and their applications?

Manual Wheel Truing Machines

- Used for truing wheels manually, requiring operator skill and precision.

- Suitable for small-scale operations or as backup equipment.

Semi-Automatic Wheel Truing Machines

- Combine manual and automated processes, reducing operator involvement.

- Provide improved accuracy and efficiency compared to manual machines.

Fully-Automatic Wheel Truing Machines

- Offer the highest level of automation, with minimal operator intervention.

- Suitable for high-volume production environments and precise wheel truing.

CNC Wheel Truing Machines

- Computer-controlled machines that provide advanced precision and repeatability.

- Used in critical applications demanding high-quality and consistent wheel truing.

3. Describe the key factors to consider when selecting a wheel truing machine for a specific application?

- Type of wheels to be trued (size, material, hardness)

- Required accuracy and surface finish

- Production volume and desired cycle time

- Budget and available resources

- Level of automation required

4. Explain the importance of proper wheel truing and its impact on wheel performance?

- Ensures smooth and even wear of the wheel, prolonging its lifespan.

- Improves wheel balance, reducing vibration and noise.

- Optimizes vehicle handling and stability by providing proper contact with the road surface.

- Enhances braking performance by ensuring uniform contact between the wheel and brake pads.

- Reduces rolling resistance, improving fuel efficiency.

5. Describe the safety precautions that must be observed when operating a wheel truing machine?

- Wear appropriate personal protective equipment (PPE) including safety glasses, gloves, and earplugs.

- Ensure the machine is properly grounded and all guards are in place.

- Inspect the wheel for damage or defects before truing.

- Secure the wheel firmly on the machine using the appropriate fixtures.

- Never operate the machine with loose clothing or jewelry that could get caught.

- Be aware of the machine’s moving parts and keep hands and body clear.

6. What are the common types of cutting tools used for wheel truing and their characteristics?

Abrasive Wheels

- Made of abrasive materials such as diamond or CBN, providing high cutting efficiency.

- Suitable for truing hard wheels and achieving precise surface finishes.

Ceramic Grinding Wheels

- Offer high speed and precision truing, with excellent wear resistance.

- Can be used to true a wide range of wheel materials.

Roller Burnishing Tools

- Used for burnishing rather than cutting, creating a smooth and work-hardened surface.

- Suitable for truing aluminum wheels and other soft materials.

7. Explain the process of balancing a wheel after truing?

- Mount the trued wheel on a wheel balancer.

- Start the balancing cycle, which rotates the wheel and measures its imbalance.

- The machine identifies the location and amount of imbalance.

- Weights are added to the wheel in specific locations to counteract the imbalance.

- The wheel is re-balanced until it meets the specified tolerance.

8. What are the different methods of inspecting a trued wheel for accuracy and quality?

Visual Inspection

- Examine the wheel surface for any visible defects or irregularities.

- Check for proper concentricity and roundness.

Dimensional Measurement

- Use calipers, micrometers, or other measuring tools to verify the wheel’s dimensions.

- Ensures adherence to specified tolerances.

Runout Measurement

- Mount the wheel on a precision spindle and measure its runout using a dial indicator.

- Indicates any deviation from true axial and radial alignment.

9. Explain the role of coolants in wheel truing and their benefits?

- Lubricate the cutting tool and reduce friction.

- Prevent excessive heat buildup, which can damage the wheel or cutting tool.

- Flush away debris generated during the truing process.

- Extend tool life and improve surface finish.

10. Describe the importance of maintaining and calibrating wheel truing machines regularly?

- Ensures optimal performance and accuracy of the machine.

- Prevents premature wear and damage to machine components.

- Maintains consistent wheel truing quality and reduces the risk of defective wheels.

- Improves safety by minimizing potential hazards.

- Extends the lifespan of the machine and reduces maintenance costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel Truing Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel Truing Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wheel Truing Machine Tenders are responsible for operating and maintaining wheel truing machines, which are used to grind and shape the wheels of trains and other vehicles. This job requires a high level of precision and attention to detail, as well as a strong understanding of the principles of wheel truing.

1. Operating Wheel Truing Machines

Wheel Truing Machine Tenders are responsible for the safe and efficient operation of wheel truing machines. This includes setting up the machine, loading and unloading wheels, and monitoring the grinding process. They must also be able to make adjustments to the machine as needed to ensure that the wheels are ground to the correct specifications.

2. Maintaining Wheel Truing Machines

In addition to operating wheel truing machines, Wheel Truing Machine Tenders are also responsible for maintaining them. This includes cleaning and lubricating the machine, as well as replacing worn parts. They must also be able to troubleshoot and repair minor problems with the machine.

3. Inspecting Wheels

Wheel Truing Machine Tenders are responsible for inspecting wheels before and after they are ground. This includes checking for cracks, chips, and other defects. They must also be able to determine if a wheel is safe to be used.

4. Record Keeping

Wheel Truing Machine Tenders are responsible for keeping records of all work performed on wheel truing machines. This includes documenting the date and time of the work, the type of work performed, and the results of the inspection.

Interview Tips

Preparing for an interview for a Wheel Truing Machine Tender position can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the Company and the Position

Before you go on an interview, it is important to do your research on the company and the position you are applying for. This will help you to better understand the company’s culture and the specific requirements of the job.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Experience

The interviewer will likely want to know about your experience in operating and maintaining wheel truing machines. Be sure to highlight your skills and experience in this area, as well as any other relevant experience that you have.

4. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or other business attire.

5. Be Punctual

Punctuality is important for any job interview, but it is especially important for a job that requires precision and attention to detail. Be sure to arrive for your interview on time, or even a few minutes early.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wheel Truing Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!