Feeling lost in a sea of interview questions? Landed that dream interview for Winder Hand but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Winder Hand interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

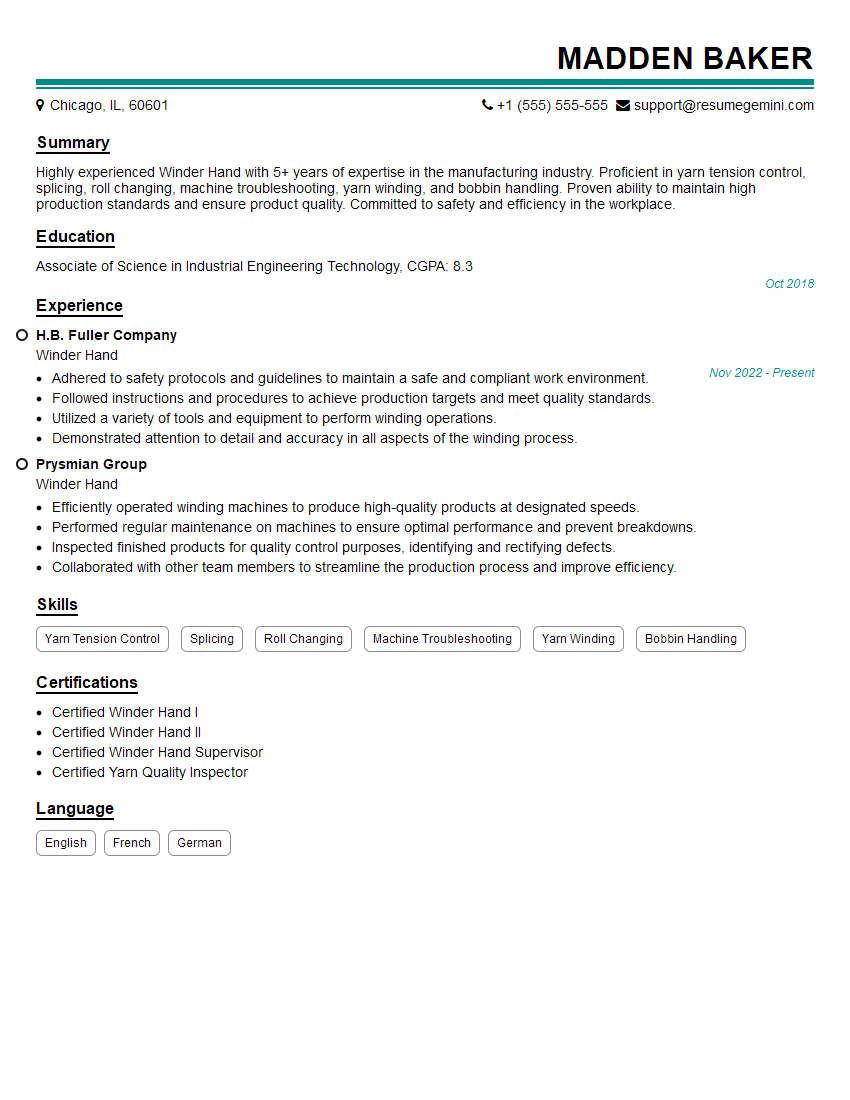

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Winder Hand

1. How do you ensure the proper tension of the yarn on the winder?

To ensure proper yarn tension, I follow these steps:

- Adjust the tensioner on the winder machine to the recommended setting for the specific yarn being used.

- Monitor the yarn as it winds onto the bobbin, observing its smoothness and evenness.

- Make fine adjustments to the tensioner as needed, based on the yarn’s behavior and the desired winding quality.

- Use a yarn tension meter to measure and verify the tension, ensuring it meets the specified requirements.

2. What techniques do you use to avoid yarn breakage during winding?

Preventing Yarn Breakage

- Proper yarn tension: Ensure that the tension is adjusted correctly to avoid both loose winding and excessive tension.

- Winder speed optimization: Set the winder speed appropriately to match the yarn speed and prevent breakage.

- Yarn path alignment: Ensure that the yarn path is aligned properly through all the guides and tensioners.

- Yarn quality inspection: Inspect the yarn before winding to identify and remove any weak or damaged sections.

Identifying and Mitigating Breakage

- Breakage monitoring: Pay attention to the winding process and listen for any unusual sounds that may indicate yarn breakage.

- Quick response: Immediately stop the winder if breakage occurs and locate the source of the problem.

3. How do you handle different types of yarn materials, such as cotton, polyester, and silk?

To handle different yarn materials effectively, I consider the following:

- Yarn properties: Understand the specific characteristics of each yarn type, such as its strength, elasticity, and moisture absorption.

- Winder settings adjustment: Adjust the winder settings, such as tension and speed, to accommodate the different properties of each yarn.

- Environmental conditions: Ensure that the winding area has appropriate temperature and humidity levels to maintain yarn quality.

- Yarn storage: Store different yarn types separately to prevent mixing and contamination.

4. What steps do you take to maintain and troubleshoot winding machines?

Preventive Maintenance

- Regular cleaning: Clean the winding machine regularly to remove dust, lint, and other debris.

- Lubrication: Lubricate the machine’s moving parts as per the manufacturer’s recommendations.

- Tension calibration: Calibrate the yarn tension system regularly to ensure accurate and consistent winding.

Troubleshooting Common Issues

- Yarn breakage: Identify the cause of breakage, such as improper tension, yarn defects, or machine malfunction.

- Uneven winding: Adjust the tension settings, check the yarn path alignment, and inspect the yarn for any inconsistencies.

- Machine malfunction: Diagnose the problem based on error codes or noise, and take appropriate action, such as replacing parts or calling for maintenance.

5. How do you ensure that the finished yarn packages meet the required specifications?

To ensure compliance with yarn specifications, I adhere to the following practices:

- Understanding yarn specifications: Thoroughly review and understand the required yarn specifications, including weight, count, twist, and package dimensions.

- Winder setup: Set up the winder machine according to the specified parameters, including tension, speed, and winding pattern.

- In-process quality checks: Conduct regular inspections during the winding process to monitor yarn quality and identify any deviations from the specifications.

- Finished package inspection: Inspect the finished yarn packages against the specifications for weight, dimensions, and other relevant parameters.

6. What is your approach to working effectively in a fast-paced production environment?

To thrive in a fast-paced production environment, I employ the following strategies:

- Time management: Prioritize tasks and allocate time efficiently to meet production deadlines.

- Organization and planning: Maintain a well-organized workspace and plan ahead to avoid interruptions and delays.

- Teamwork and communication: Collaborate effectively with colleagues to resolve issues quickly and keep production running smoothly.

- Continuous improvement: Seek opportunities to streamline processes and improve efficiency.

7. How do you handle situations when there are multiple machines running simultaneously?

When managing multiple machines simultaneously, I follow these practices:

- Prioritizing tasks: Determine the most critical machines and tasks, and prioritize them accordingly.

- Monitoring and multitasking: Keep a close eye on all machines while multitasking to ensure they are running smoothly.

- Preventive maintenance: Conduct regular maintenance on all machines to minimize the likelihood of breakdowns.

- Time management: Allocate time effectively to address each machine’s needs without compromising quality or productivity.

8. What techniques do you use to minimize waste and maintain a high level of quality in your work?

To minimize waste and maintain quality, I implement the following techniques:

- Yarn tension optimization: Adjust the yarn tension carefully to prevent yarn breakage and reduce the amount of waste produced.

- Regular machine maintenance: Keep the winding machines well-maintained to avoid breakdowns and ensure consistent yarn quality.

- Quality checks: Conduct regular inspections of the yarn and finished packages to detect any defects or inconsistencies.

- Waste reduction initiatives: Explore and implement waste reduction initiatives, such as recycling yarn scraps and optimizing winding patterns.

9. What is your experience with different winding techniques, such as cross winding and parallel winding?

I have experience with various winding techniques, including:

- Cross winding: I understand the principles of cross winding, which involves winding the yarn back and forth across the bobbin to create a stable and compact package.

- Parallel winding: I am also proficient in parallel winding, where the yarn is wound parallel to the bobbin’s axis, resulting in a cylindrical package.

- Skein winding: I have experience in skein winding, which involves winding the yarn into a loose, coiled form for specific applications.

10. How do you stay updated with the latest advancements and best practices in the winding industry?

To stay updated with the latest advancements and best practices in the winding industry, I engage in the following activities:

- Industry publications: I read industry magazines, journals, and online articles to stay informed about new technologies, techniques, and trends.

- Conferences and workshops: I attend industry conferences and workshops to learn from experts and network with peers.

- Manufacturer training: I participate in training programs offered by winding machine manufacturers to enhance my knowledge and skills.

- Collaboration with colleagues: I share knowledge and best practices with my colleagues and seek their insights on new developments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Winder Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Winder Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Winder Hand is primarily responsible for operating winding machines to produce coils, transformers, and other electrical components. The key job responsibilities include:

1. Machine Operation

Set up, operate, and maintain winding machines to produce electrical components such as coils, transformers, and armatures.

- Adjust machine settings according to production specifications.

- Monitor machine performance and make necessary adjustments.

2. Material Handling

Load and unload materials into and out of winding machines.

- Inspect materials for defects and ensure they meet quality standards.

- Maintain proper storage and handling techniques.

3. Quality Control

Conduct visual inspections of finished products to ensure they meet specifications.

- Use measuring tools and gauges to verify dimensions and tolerances.

- Identify and report any defects or non-conformances.

4. Maintenance

Perform basic maintenance tasks on winding machines and associated equipment.

- Clean and lubricate machines as per maintenance schedules.

- Identify and report any mechanical or electrical issues.

Interview Tips

To ace a job interview for a Winder Hand position, candidates should thoroughly prepare and present themselves in a professional and confident manner. Here are some interview preparation tips and hacks:

1. Research the Company and Role

Before the interview, candidates should research the company and the specific Winder Hand role to understand the company’s culture, values, and expected responsibilities.

- Visit the company website to learn about their products, services, and mission.

- Review the job description carefully to identify the key qualifications and requirements.

2. Practice Common Interview Questions

Candidates should anticipate and prepare answers to common interview questions related to their skills, experience, and qualifications.

- Practice introducing themselves, describing their relevant skills, and explaining their interest in the role.

- Prepare examples of their work experience that demonstrate their technical abilities and problem-solving skills.

3. Showcase Technical Expertise

Winder Hands should highlight their technical expertise and proficiency in operating winding machines.

- Demonstrate a strong understanding of winding techniques, machine settings, and quality control procedures.

- Provide examples of successful projects or initiatives that showcase their technical abilities.

4. Emphasize Attention to Detail and Quality

Attention to detail and a commitment to quality are essential for a Winder Hand. Candidates should emphasize these attributes in their interview responses.

- Describe their commitment to following instructions and maintaining high standards of accuracy.

- Provide examples of how they have identified and resolved quality issues in their previous roles.

5. Highlight Teamwork and Communication Skills

Winder Hands often work in a team environment and may need to communicate with supervisors, engineers, and other staff members.

- Demonstrate effective communication and interpersonal skills by providing examples of their ability to collaborate and work as part of a team.

- Emphasize their ability to follow instructions, ask clarifying questions, and provide clear and concise information to others.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Winder Hand, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Winder Hand positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.