Are you gearing up for a career in Wire Inserter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wire Inserter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

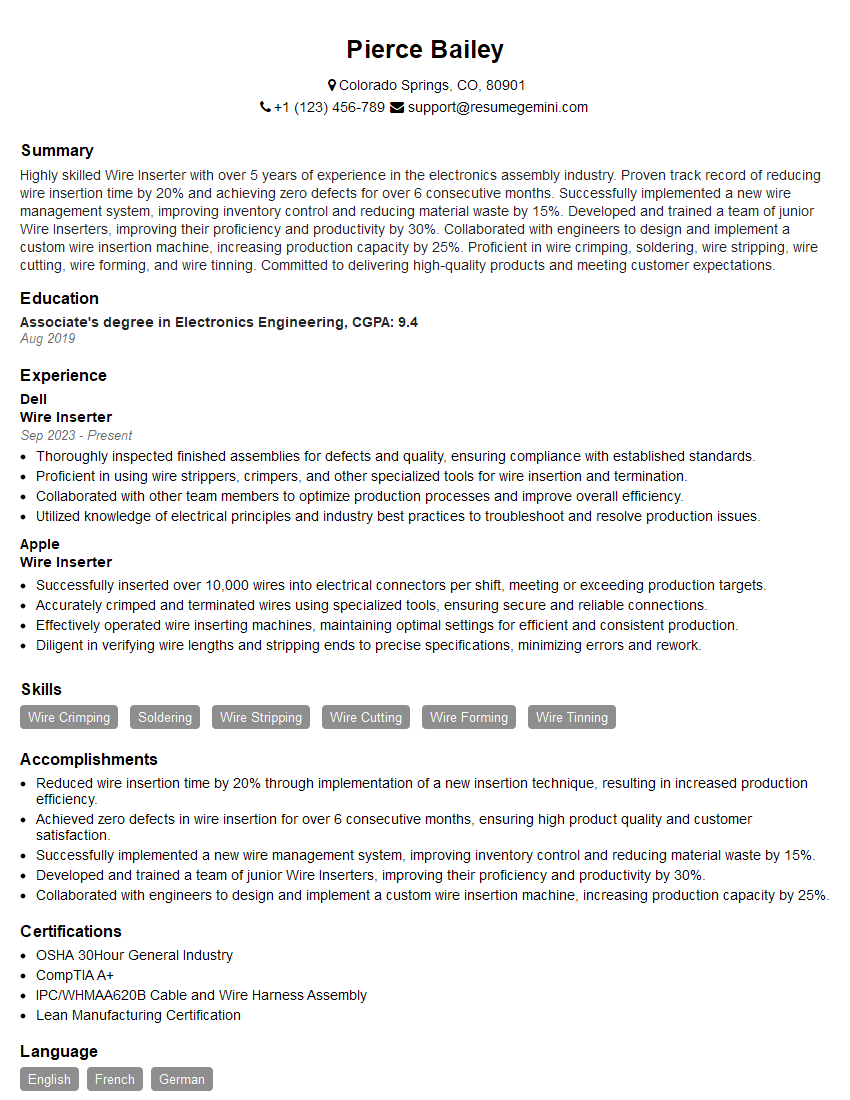

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Inserter

1. Describe the process of inserting wires into a terminal block?

The process of inserting wires into a terminal block involves several steps:

- Prepare the Wire: Strip the insulation from the end of the wire, exposing the bare copper conductor.

- Insert the Wire: Push the stripped end of the wire into the appropriate opening in the terminal block.

- Tighten the Screw: Use a screwdriver to tighten the screw that holds the wire in place, ensuring a secure connection.

- Verify Connection: Gently tug on the wire to ensure it is securely inserted and there is no loose connection.

2. What types of terminal blocks have you worked with and what are their advantages and disadvantages?

Screw-Type Terminal Blocks

- Advantages: Reliable and secure connections, widely available, relatively low cost.

- Disadvantages: Time-consuming to tighten screws, can loosen over time if not properly maintained.

Spring-Type Terminal Blocks

- Advantages: Quick and easy to use, time-saving during installation.

- Disadvantages: Lower current carrying capacity compared to screw-type, may not be as secure in high-vibration applications.

Push-In Terminal Blocks

- Advantages: Tool-less termination, fast and efficient for large wire count applications.

- Disadvantages: Not as reliable as screw-type blocks, may not handle high currents as well.

3. What is the importance of proper wire stripping and gauge selection when inserting wires into a terminal block?

Proper wire stripping and gauge selection are crucial for several reasons:

- Electrical Safety: Ensuring the correct amount of bare copper conductor is exposed prevents short circuits and potential electrical hazards.

- Secure Connection: Properly stripped wires make better contact with the terminals, ensuring a secure connection and preventing wire slippage.

- Current Capacity: Selecting the appropriate wire gauge ensures the wire can handle the intended current flow without overheating or failing.

4. How do you handle and store wires properly to prevent damage during the insertion process?

Proper handling and storage of wires are essential to prevent damage:

- Avoid Kinking: Gently bend wires without kinking or sharp angles, as this can weaken the conductor.

- Use Wire Reels: Store wires on reels to prevent tangling and damage during transportation.

- Protect from Moisture: Keep wires dry and protected from moisture to prevent corrosion.

- Label Wires: Label wires clearly for easy identification and organization.

5. What tools and equipment are essential for a Wire Inserter?

- Wire Strippers

- Screwdrivers (for screw-type terminal blocks)

- Crimping Tool (for insulated terminals)

- Terminal Block Inserter (optional, but can speed up insertion)

- Wire Gauge Tool

- Safety Glasses

6. How do you ensure the accurate and consistent insertion of wires into terminal blocks?

Accuracy and consistency can be achieved through the following measures:

- Use a Wire Gauge Tool: Ensure the correct wire size is used for the terminal block.

- Follow Wire Stripping Guidelines: Stripping wires to the recommended length ensures proper contact.

- Check Terminal Block Capacity: Verify the number of wires that can be inserted into each terminal block.

- Use Proper Insertion Tools: Terminal block inserters can help guide wires accurately into place.

- Inspect Connections: Visually inspect the connections to ensure they are secure and properly inserted.

7. How do you troubleshoot common issues related to wire insertion, such as loose connections or incorrect wiring?

Troubleshooting common issues:

- Loose Connections: Check the tightness of the screw or spring terminals, and ensure the wire is fully inserted.

- Incorrect Wiring: Verify the wire colors and terminal designations to ensure proper connections.

- Damaged Wires: Inspect wires for any damage or insulation breaches that may compromise the connection.

- Terminal Block Overload: Check if the terminal block is overloaded with wires, as this can cause overheating and loose connections.

- Faulty Terminal Block: Inspect the terminal block itself for any damage or defects that could affect the connections.

8. How do you stay updated with industry standards and best practices for wire insertion?

- Attend training sessions or workshops.

- Read industry publications and articles.

- Consult with experienced electricians or supervisors.

- Follow industry organizations and online forums.

- Stay informed about new products and technologies related to wire insertion.

9. Describe a challenging situation you faced during wire insertion and how you overcame it?

Provide an example of a specific situation encountered, the challenges faced, and the steps taken to successfully resolve the issue.

10. Explain your understanding of the importance of quality control in wire insertion?

Emphasize the impact of quality control on ensuring reliable electrical connections, preventing hazards, and maintaining equipment functionality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Inserter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Inserter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wire Inserters are responsible for maintaining and operating wire insertion machines to insert wires into electronic components, ensuring accurate and efficient production.

1. Machine Operation and Maintenance

Monitor wire insertion machines for proper operation and diagnose any malfunctions.

- Calibrate and adjust machines to meet specifications.

- Conduct routine maintenance, including cleaning and lubricating.

2. Wire Insertion

Insert wires into electronic components to create electrical connections.

- Select and load appropriate wires based on specifications.

- Operate machines to insert wires with precision and accuracy.

3. Quality Control

Inspect inserted wires to ensure they meet quality standards.

- Use gauges and measuring tools to verify wire placement.

- Identify and correct any defects in wire insertion.

4. Production Monitoring

Monitor production output and maintain records of completed work.

- Track production targets and identify areas for improvement.

- Maintain logs of machine performance and wire usage.

Interview Tips

To ace an interview for a Wire Inserter position, candidates should prepare by understanding the key responsibilities and demonstrating relevant skills and experience.

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends.

- Visit the company’s website and read industry publications.

- Research similar businesses to gain insights into industry practices.

2. Highlight Relevant Skills and Experience

Emphasize your ability to operate and maintain wire insertion machines.

- Quantify your accomplishments with specific metrics, such as increased production efficiency.

- Showcase your understanding of wire insertion techniques and quality control processes.

3. Prepare for Technical Questions

Be ready to answer questions about machine operation, troubleshooting, and wire insertion techniques.

- Review the job description and prepare for specific questions related to the machines or processes used.

- Practice troubleshooting scenarios and explain your approach to resolving common issues.

4. Show Enthusiasm and Eagerness

Demonstrate your interest in the role and the opportunity to contribute to the company.

- Ask thoughtful questions about the position and company.

- Express your enthusiasm for learning and developing within the industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wire Inserter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!