Are you gearing up for an interview for a Wood Web Weaving Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wood Web Weaving Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

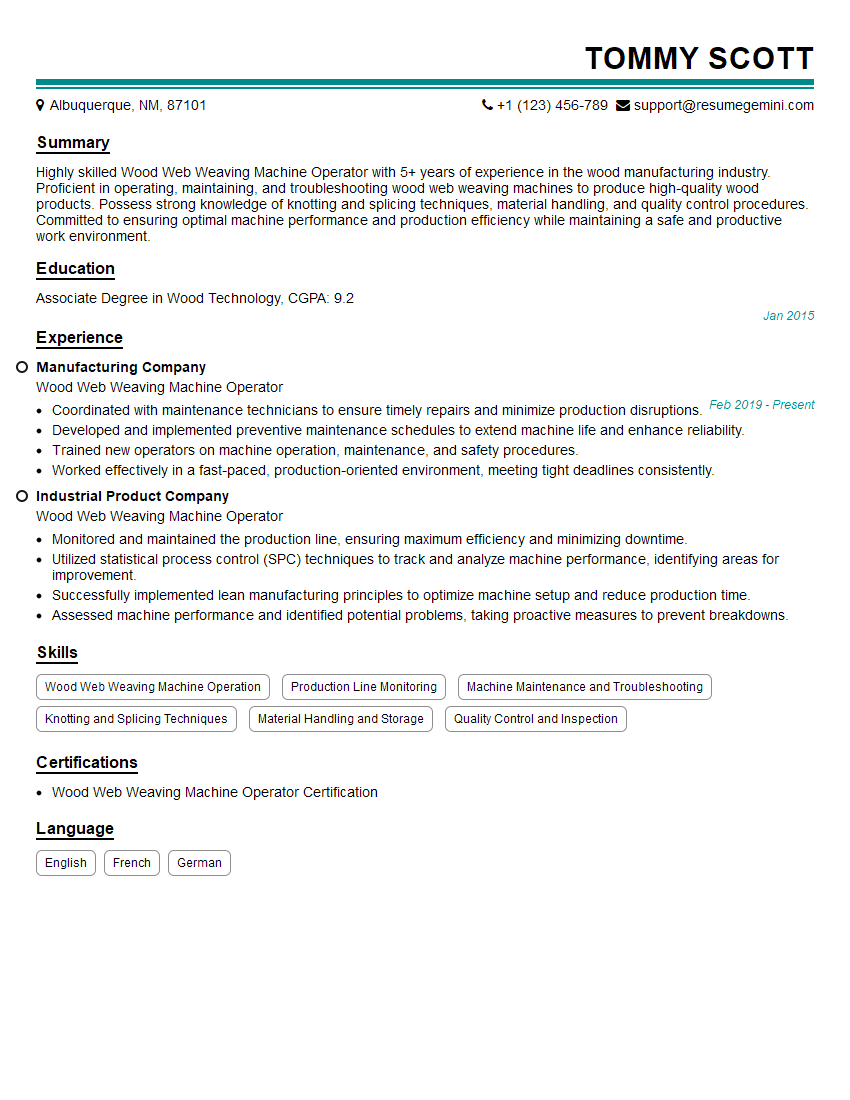

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Web Weaving Machine Operator

1. Explain the process of setting up a Wood Web Weaving Machine.

- Gather materials and tools, including warp and weft yarns, machine instructions, and measuring devices.

- Prepare the warp yarns by winding them onto the warp beam and threading them through the machine.

- Set up the weft yarns by loading them into the weft shuttle and threading them into the machine.

- Adjust the machine settings, such as speed, tension, and weaving pattern, according to the fabric specifications.

- Start the machine and monitor its operation to ensure proper weaving.

2. Describe the different types of knots used in the production of wood web fabrics.

- Single Knot: Creates a plain weave, characterized by evenly spaced warp and weft yarns.

- Double Knot: Forms a more durable weave with closely packed yarns, resulting in a thicker and stronger fabric.

- Open Knot: Leaves spaces between warp and weft yarns, creating a lighter and more airy fabric.

- Kep Knot: Produces a twill pattern with diagonal lines, adding texture and strength to the fabric.

- Swept Knot: Forms a complex pattern with alternating plain and twill weaves, creating visual interest and durability.

3. How would you troubleshoot a Wood Web Weaving Machine that is not producing uniform fabric?

- Check the warp and weft yarns for any knots, breaks, or uneven tension.

- Inspect the machine settings to ensure accuracy and consistency.

- Examine the shuttle for any damage or obstructions that could affect weft insertion.

- Inspect the reed and heddles for wear or damage that can cause misalignment.

- Check the take-up mechanism to ensure proper winding of the woven fabric.

4. How do you calculate the production capacity of a Wood Web Weaving Machine?

- Determine the machine speed in revolutions per minute (RPM).

- Estimate the weft insertion rate per revolution.

- Calculate the fabric width based on the number of warps used.

- Multiply the RPM, weft insertion rate, and fabric width to obtain the production capacity in square meters per hour.

- Consider efficiency factors and machine downtime for a realistic estimate.

5. Explain the importance of regular maintenance and calibration in Wood Web Weaving Machine operation.

- Prevents breakdowns and extends machine life by identifying potential issues early.

- Ensures accurate and consistent weaving, maintaining product quality.

- Reduces downtime and improves productivity by addressing minor problems before they become major repairs.

- Improves safety by detecting and устранение potential hazards.

- Optimizes machine settings for specific fabric requirements, improving efficiency.

6. What are the safety precautions to observe when operating a Wood Web Weaving Machine?

- Wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Keep hands and loose clothing away from moving parts.

- Securely tie back long hair to prevent entanglement.

- Follow machine safety instructions and never attempt to override safeguards.

- Regularly inspect the machine for potential hazards and report any issues immediately.

7. How would you maintain a Wood Web Weaving Machine in optimal condition?

- Daily: Clean the machine, inspect the shuttle and reed, and lubricate moving parts.

- Weekly: Check the motor and electrical components for proper operation.

- Monthly: Conduct a thorough inspection of the machine, including belts, pulleys, and gears.

- Semi-Annually: Perform a comprehensive maintenance with the assistance of a qualified technician.

- Annually: Schedule a major overhaul to address any wear or tear and ensure peak performance.

8. Describe the different types of wood used in the production of wood web fabrics.

- Pine: Commonly used for its affordability and availability, produces a fabric with a moderate strength and durability.

- Spruce: Known for its flexibility and elasticity, creating a fabric that is strong and resistant to stretching.

- Fir: Offers high strength and splinter resistance, suitable for applications requiring durability and impact absorption.

- Redwood: A durable and weather-resistant wood, producing a fabric ideal for outdoor and moisture-prone environments.

- Cedar: Naturally resistant to insects and decay, resulting in a fabric with excellent longevity and pest resistance.

9. Explain the role of warp yarns in the structure and properties of wood web fabrics.

- Determine the fabric’s length and strength, providing the backbone of the weave.

- Influence the fabric’s texture and stiffness, depending on the thickness and spacing of the yarns.

- Contribute to the fabric’s appearance by creating patterns and visual effects.

- Can be made from various materials, such as cotton, linen, or synthetic fibers, affecting the fabric’s breathability and drape.

- Proper tension and alignment of warp yarns are crucial for the overall quality and uniformity of the fabric.

10. How do you ensure the quality of wood web fabrics throughout the production process?

- Regularly inspect raw materials and discard any faulty or damaged wood.

- Monitor machine settings and make necessary adjustments to maintain consistent fabric quality.

- Conduct frequent visual inspections of the fabric during weaving to identify any defects or irregularities.

- Perform tensile strength tests to ensure the fabric meets specifications.

- Establish a quality control system to track and document production parameters, allowing for continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Web Weaving Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Web Weaving Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Web Weaving Machine Operators are responsible for operating and maintaining wood web weaving machines that produce materials used in a variety of applications, including furniture, flooring, and automotive parts.

1. Equipment Operation

Operate wood web weaving machines to produce a variety of products according to established specifications.

- Monitor machine functions, such as speed, tension, and temperature, to ensure optimal performance.

- Adjust machine settings and make repairs as needed to maintain production efficiency.

2. Material Handling

Handle and transport raw materials and finished products in a safe and efficient manner.

- Load and unload materials from machines using forklifts or other equipment.

- Inspect materials for defects and ensure they meet quality standards.

3. Quality Control

Inspect finished products to ensure they meet specifications and customer requirements.

- Identify and correct any defects in the materials or workmanship.

- Maintain records of production and quality control data.

4. Safety and Maintenance

Follow safety procedures and maintain a clean and organized work area.

- Wear appropriate safety gear, such as goggles, gloves, and earplugs.

- Perform routine maintenance and cleaning on machines to ensure they are in good working order.

Interview Tips

Preparing for an interview can be daunting, but with the right approach, you can increase your chances of making a positive impression and securing the job you want.

1. Research the Company and Job

Take the time to learn about the company and the specific role you are applying for. This will help you understand the company’s culture, values, and goals, and tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on trends.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked. It is helpful to practice answering these questions in advance so that you can feel confident and articulate during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- What are the biggest challenges facing the company right now?

- What is the company’s culture like?

- What are the opportunities for professional growth within the company?

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Choose clothing that is clean, pressed, and appropriate for the industry.

- Be punctual and allow yourself plenty of time to get to the interview location.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Web Weaving Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.