Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wrapper Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wrapper Operator so you can tailor your answers to impress potential employers.

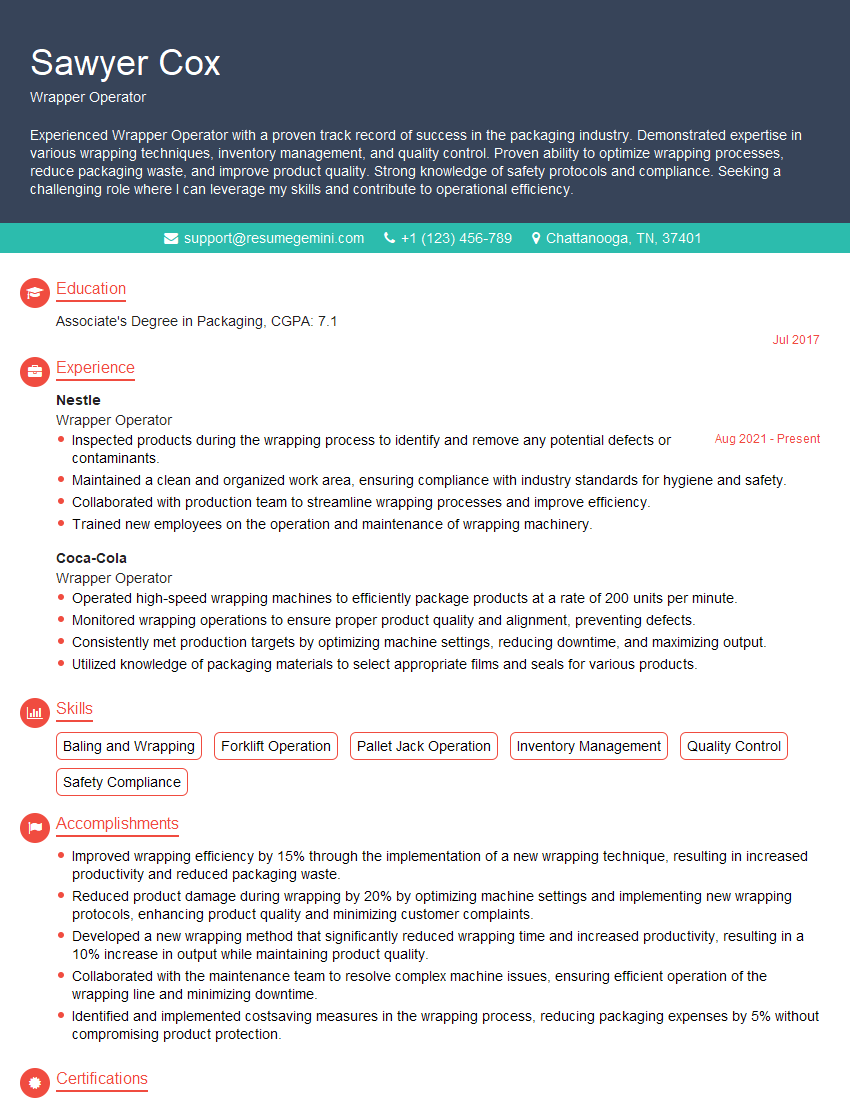

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wrapper Operator

1. Explain the process of wrapping products using a wrapping machine?

The process of wrapping products using a wrapping machine involves:

- Loading the machine with the product to be wrapped

- Selecting the appropriate wrapping material, such as plastic or cellophane

- Setting the machine’s controls, including the wrapping speed and tension

- Starting the machine and monitoring the wrapping process

- Unloading the wrapped products

2. What is the difference between a manual wrapping machine and an automatic wrapping machine?

Manual wrapping machine

- Requires an operator to manually load the product, select the wrapping material, and start the machine

- The operator must also monitor the wrapping process and unload the wrapped products

Automatic wrapping machine

- Does not require an operator to manually load the product, select the wrapping material, or start the machine

- The machine automatically loads the product, selects the wrapping material, and starts the machine

- The machine also monitors the wrapping process and unloads the wrapped products

3. What are the different types of wrapping materials used on a wrapping machine?

Various wrapping materials used on a wrapping machine include:

- Plastic

- Cellophane

- Paper

- Foil

4. Describe the safety precautions to consider when operating a wrapping machine?

Safety precautions to consider when operating a wrapping machine include:

- Wearing appropriate safety gear, including gloves, safety glasses, and ear protection

- Keeping the work area clean and free of debris

- Never placing hands or other body parts near the moving parts of the machine

- Following the manufacturer’s instructions for operating the machine

5. How do you troubleshoot a wrapping machine that is not wrapping products correctly?

Troubleshooting a wrapping machine that is not wrapping products correctly involves following steps:

- Checking the machine’s settings to ensure they are correct

- Inspecting the wrapping material to ensure it is not damaged or defective

- Checking the machine’s sensors to ensure they are functioning properly

- Lubricating the machine’s moving parts

- Restarting the machine

6. What are the different maintenance procedures required for a wrapping machine?

Maintenance procedures for a wrapping machine include:

- Regularly cleaning the machine

- Lubricating the machine’s moving parts

- Inspecting the machine’s electrical components

- Checking the machine’s sensors

- Performing regular safety checks

7. Describe the different types of products that can be wrapped on a wrapping machine?

Various products that can be wrapped on a wrapping machine include:

- Food products

- Pharmaceutical products

- Electronics

- Cosmetics

- Industrial products

8. How do you ensure that the wrapped products meet the required quality standards?

Ensuring wrapped products meet quality standards involves:

- Using high-quality wrapping materials

- Setting the machine’s controls correctly

- Monitoring the wrapping process

- Inspecting the wrapped products

- Following quality control procedures

9. Describe the importance of following proper wrapping procedures?

Following proper wrapping procedures is important to:

- Ensure the products are protected from damage

- Maintain the products’ quality

- Meet customer requirements

- Comply with safety regulations

- Maximize the efficiency of the wrapping process

10. How do you handle situations when the wrapping machine malfunctions?

When a wrapping machine malfunctions, I take the following steps:

- Identify the cause of the malfunction

- Stop the machine and isolate it from the power source

- Follow the manufacturer’s instructions for troubleshooting and repairs

- If necessary, contact a qualified technician for assistance

- Restart the machine and ensure it is functioning properly before resuming operation

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wrapper Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wrapper Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wrapper Operators are responsible for packaging products and ensuring their integrity throughout the packaging process.

1. Packaging Products

• Load and unload products onto and from packaging machines.

• Monitor the packaging process and make adjustments as needed.

• Ensure that products are packaged correctly and securely.

2. Maintaining Packaging Equipment

• Clean and inspect packaging equipment regularly.

• Identify and troubleshoot any problems with packaging equipment.

• Perform minor repairs and adjustments to packaging equipment.

3. Quality Assurance

• Inspect packaged products for defects.

• Reject and rework any defective products.

• Maintain records of product quality.

4. Safety

• Follow all safety procedures and regulations.

• Use proper personal protective equipment.

• Report any safety hazards.

Interview Tips

Preparing for an interview as a Wrapper Operator requires a clear understanding of the role and the ability to showcase your relevant skills and experience.

1. Research the Company and Position

• Learn about the company’s industry, products, and culture.

• Review the job description thoroughly to identify the specific requirements of the position.

2. Highlight Your Packaging Skills

• Emphasize your experience in operating packaging machines and maintaining equipment.

• Provide examples of how you ensured product quality and met production targets.

3. Demonstrate Your Attention to Detail

• Explain how your strong attention to detail enables you to consistently package products accurately and efficiently.

• Describe your ability to identify and resolve packaging issues promptly.

4. Communicate Your Safety Awareness

• Stress your commitment to following safety procedures and ensuring a safe work environment.

• Share examples of how you identified and reported safety hazards in previous roles.

Next Step:

Now that you’re armed with the knowledge of Wrapper Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wrapper Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini