Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tiltrotor Crew Chief interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tiltrotor Crew Chief so you can tailor your answers to impress potential employers.

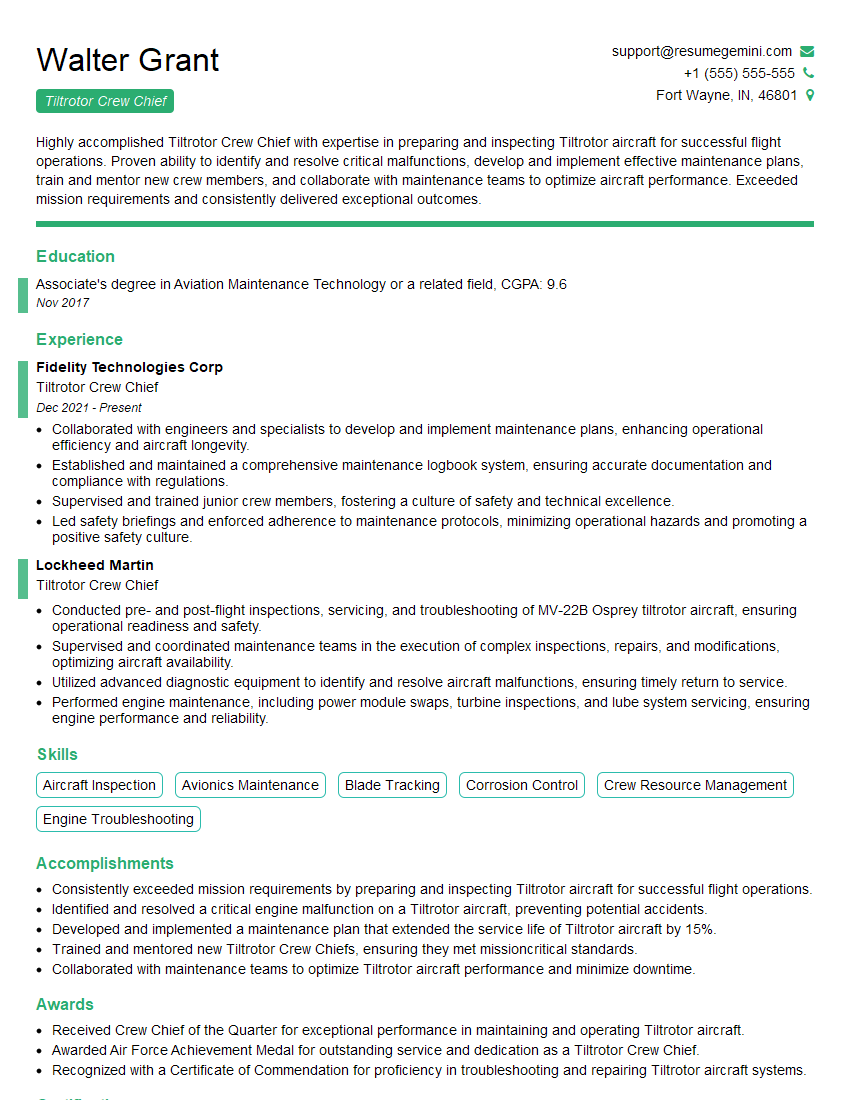

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tiltrotor Crew Chief

1. What are the different types of inspections performed on a tiltrotor aircraft, and what are the key points to look for during each type of inspection?

answer:

- Daily Inspection: Checks fluid levels, tire pressure, and general aircraft condition.

- Weekly Inspection: More detailed inspection of aircraft systems, including engine, transmission, and flight controls.

- Monthly Inspection: Comprehensive inspection covering all aircraft systems, including major components and structural integrity.

- Phase Inspection: Scheduled maintenance inspection performed at specific intervals to ensure aircraft safety and reliability.

2. Describe the procedures for performing a flight control rigging inspection on a tiltrotor aircraft.

answer:

- Visual Inspection: Check for damage or corrosion on flight control surfaces and linkages.

- Functional Check: Test the movement and response of flight controls throughout their full range of motion.

- Rigging Adjustments: Make necessary adjustments to ensure proper alignment and balance of flight controls.

- Documentation: Record all findings and adjustments made during the inspection.

3. What are the recommended torque values for the bolts used in the main rotor hub assembly of a tiltrotor aircraft?

answer:

- Depends on the specific aircraft model and manufacturer’s specifications.

- Typically, torque values range from 100 to 300 ft-lbs, depending on bolt size and location.

- Precise torque values should be obtained from the aircraft maintenance manual.

4. Describe the process for troubleshooting an electrical fault on a tiltrotor aircraft.

answer:

- Isolate the Fault: Identify the affected system or component.

- Inspect Wiring: Check for loose connections, damaged wires, or shorts.

- Test Components: Use electrical testers to check continuity, resistance, and voltage.

- Consult Wiring Diagrams: Utilize aircraft electrical diagrams to locate faulty components or circuits.

- Replace or Repair: Replace faulty components or repair damaged wiring as necessary.

5. What are the safety precautions that must be observed when working on a tiltrotor aircraft’s hydraulic system?

answer:

- Release Hydraulic Pressure: Before opening any hydraulic lines, release pressure by using the designated pressure relief valve.

- Wear Protective Gear: Wear eye protection, gloves, and appropriate clothing to protect against hydraulic fluid exposure.

- Use Proper Tools: Use hydraulic-specific tools and equipment to prevent cross-contamination or damage to the system.

- Maintain Cleanliness: Ensure the work area and components are clean to prevent contamination of the hydraulic fluid.

- Follow Manufacturer’s Instructions: Adhere to the aircraft maintenance manual and manufacturer’s guidelines for safe handling of the hydraulic system.

6. Describe the different types of fuel systems used in tiltrotor aircraft and their advantages and disadvantages.

answer:

Types of Fuel Systems:

- Single-Point Refueling: Single refueling point for both fuel tanks, reducing potential for contamination.

- Dual-Point Refueling: Two separate refueling points for each fuel tank, increasing efficiency but with higher risk of misfueling.

- Centralized Refueling: Fuel tanks located centrally, simplifying refueling but requiring additional pumps and plumbing.

Advantages and Disadvantages:

- Single-Point: Convenient, reduces risk of contamination, but can be slower than dual-point.

- Dual-Point: Faster refueling, but increased risk of misfueling and contamination.

- Centralized: Simplified refueling, but more complex system with potential for leaks and failures.

7. What are the differences between an engine nacelle and a cowling, and what are their respective functions?

answer:

- Engine Nacelle:

- Encloses the engine and other components, providing protection and aerodynamics.

- Houses engine mounts, accessories, and exhaust systems.

- Cowling:

- Removable cover on the engine nacelle that allows access for maintenance and inspections.

- Directs cooling airflow around the engine and accessories.

8. Describe the procedures for performing a power check on a tiltrotor aircraft’s engines.

answer:

- Prepare Aircraft: Ensure aircraft is secured, instruments are calibrated, and all systems are operational.

- Set Test Conditions: Establish specific power settings, altitude, and atmospheric conditions as per the aircraft maintenance manual.

- Monitor Instruments: Observe and record engine parameters such as power output, fuel flow, and exhaust gas temperature.

- Compare Results: Analyze the recorded data and compare it to manufacturer’s specifications to identify any deviations or anomalies.

- Document Findings: Record all test results and observations in the aircraft logbooks for future reference.

9. What are the common causes of engine vibrations in tiltrotor aircraft, and how can they be diagnosed and resolved?

answer:

Common Causes:

- Unbalanced propeller or blades

- Engine mount problems

- Loose or damaged engine components

Diagnosis and Resolution:

- Vibration Analysis: Use vibration monitoring equipment to identify the source and frequency of the vibration.

- Visual Inspection: Examine engine components for any visible signs of damage or wear.

- Functional Tests: Conduct engine tests at different power settings to observe vibration patterns.

- Repair or Replacement: Replace or repair faulty components as necessary to eliminate the source of vibration.

10. Describe the significance of proper torque application in tiltrotor aircraft maintenance, and what are the potential consequences of over-torquing or under-torquing bolts?

answer:

- Over-torquing:

- Can damage bolts, threads, and surrounding components.

- May cause premature failure or even catastrophic structural damage.

- Under-torquing:

- Can lead to loose bolts, which can vibrate and cause further damage.

- May result in component failure or even separation.

- Proper Torque:

- Ensures correct clamping force on bolts.

- Prevents damage to components and maintains structural integrity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tiltrotor Crew Chief.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tiltrotor Crew Chief‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tiltrotor Crew Chiefs are responsible for the safe and efficient operation of tiltrotor aircraft. They perform a variety of tasks, including:

1. Aircraft Maintenance

Inspecting, servicing, and repairing aircraft systems and components

- Inspecting aircraft structures for damage

- Servicing aircraft engines and fuel systems

- Repairing aircraft electrical and hydraulic systems

2. Flight Operations

Preparing aircraft for flight

- Conducting pre-flight inspections

- Loading and unloading cargo and personnel

- Operating aircraft systems during flight

3. Safety

Ensuring the safety of aircraft, crew, and passengers

- Following all safety procedures

- Responding to emergencies

- Training and supervising junior crew members

4. Administration

Maintaining aircraft records and documentation

- Keeping track of maintenance history

- Preparing flight plans and weather reports

- Ordering and managing supplies

Interview Tips

To ace the interview for a Tiltrotor Crew Chief position, it is important to prepare thoroughly. Here are some tips:

1. Research the job and the company

Take some time to learn about the specific requirements of the job you are applying for. Visit the company’s website to learn about their culture and values. This will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about their history, mission, and values.

- Read articles and news stories about the company to learn about their recent developments and accomplishments.

- Talk to people who work or have worked for the company to get their insights into the company culture.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” Practice answering these questions in a clear and concise way. You can also prepare some questions of your own to ask the interviewer.

- Use the STAR method to answer interview questions. STAR stands for Situation, Task, Action, Result. When answering a question, start by describing the situation you were in, then explain the task you were responsible for, describe the actions you took, and finally share the results of your actions.

- Tailor your answers to the specific job you are applying for. Highlight the skills and experience that are most relevant to the job requirements.

- Be enthusiastic and positive in your answers. Show the interviewer that you are genuinely interested in the job and that you are confident in your ability to do the job well.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also arrive on time for your interview. Being late shows that you are not respectful of the interviewer’s time.

- Choose clothing that is clean, pressed, and fits well.

- Avoid wearing clothing that is too revealing, too casual, or too flashy.

- Arrive at the interview location at least 15 minutes early. This will give you time to relax and prepare for the interview.

4. Be yourself and be genuine

The most important thing is to be yourself and be genuine. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and open about your skills, experience, and motivations.

- Be authentic and don’t try to be someone you’re not.

- Show the interviewer your passion for aviation and your commitment to safety.

- Be confident in your abilities, but don’t be arrogant.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tiltrotor Crew Chief interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!