Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted PVC Monitor (Polyvinyl Chloride Monitor) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

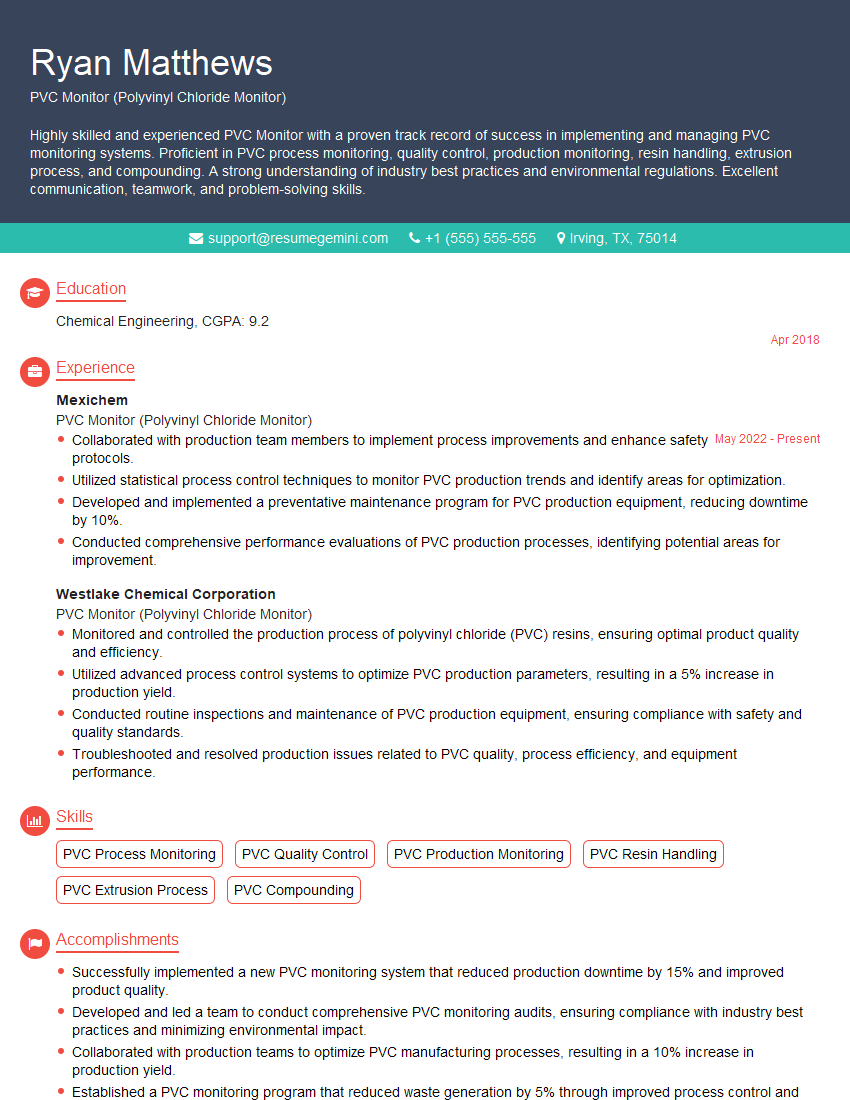

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For PVC Monitor (Polyvinyl Chloride Monitor)

1. Explain the basic principles of operation of a PVC monitor.

A PVC monitor is a device used to measure the concentration of polyvinyl chloride (PVC) in air. It operates on the principle of infrared (IR) spectroscopy. The IR light is passed through the air sample, and the absorption of light at specific wavelengths is measured. The amount of absorption is directly proportional to the concentration of PVC in the air.

- The PVC monitor draws a sample of air through a sampling line.

- The air sample passes through a filter to remove particulate matter.

- The filtered air sample passes through an IR light source.

- The IR light is absorbed by the PVC molecules in the air sample.

- The amount of absorption is measured by a detector.

- The detector signal is converted to a concentration reading.

2. What are the key technical specifications of a PVC monitor?

Measurement range

- The measurement range of a PVC monitor is the range of concentrations that it can measure. The measurement range is typically specified in parts per million (ppm) or parts per billion (ppb).

Accuracy

- The accuracy of a PVC monitor is the degree to which its readings are close to the true concentration of PVC in the air.

Precision

- The precision of a PVC monitor is the degree to which its readings are reproducible.

Response time

- The response time of a PVC monitor is the time it takes for the monitor to reach 90% of its final reading after a change in the concentration of PVC in the air.

Detection limit

- The detection limit of a PVC monitor is the lowest concentration of PVC that the monitor can reliably detect.

3. What are the different types of PVC monitors available?

- Continuous PVC monitors measure the concentration of PVC in air continuously.

- Grab sample PVC monitors measure the concentration of PVC in air at a specific point in time.

- Personal PVC monitors are worn by individuals to measure their exposure to PVC.

4. What are the advantages and disadvantages of using a PVC monitor?

Advantages

- PVC monitors are relatively inexpensive to purchase and operate.

- PVC monitors are easy to use and maintain.

- PVC monitors provide real-time data on the concentration of PVC in air.

Disadvantages

- PVC monitors can be affected by other chemicals in the air.

- PVC monitors may not be able to measure the concentration of PVC in air accurately at very low or very high concentrations.

- PVC monitors can be bulky and difficult to transport.

5. How do you calibrate a PVC monitor?

PVC monitors are calibrated using a known concentration of PVC in air. The monitor is exposed to the known concentration of PVC, and the monitor’s reading is adjusted to match the known concentration.

- Zero calibration: The monitor is exposed to clean air, and the monitor’s reading is adjusted to zero.

- Span calibration: The monitor is exposed to a known concentration of PVC, and the monitor’s reading is adjusted to match the known concentration.

6. How do you maintain a PVC monitor?

PVC monitors require regular maintenance to ensure that they are working properly. Maintenance tasks include:

- Cleaning the monitor’s filter.

- Checking the monitor’s calibration.

- Replacing the monitor’s batteries.

7. What are the safety precautions that should be taken when using a PVC monitor?

- PVC monitors should be used in accordance with the manufacturer’s instructions.

- PVC monitors should be used in a well-ventilated area.

- Do not use PVC monitors in the presence of flammable gases or liquids.

- Do not open the PVC monitor’s housing.

8. What are the applications of a PVC monitor?

- PVC monitors are used to measure the concentration of PVC in air in a variety of settings, including:

- Industrial workplaces

- Commercial buildings

- Residential homes

- Environmental monitoring

9. What are the future trends in PVC monitoring technology?

- The development of more accurate and precise PVC monitors.

- The development of smaller and more portable PVC monitors.

- The development of wireless PVC monitors.

- The development of PVC monitors that can measure multiple chemicals simultaneously.

10. Tell me about a time when you used a PVC monitor to solve a problem.

I have used a PVC monitor to solve a problem at a manufacturing plant. The plant was experiencing high levels of PVC in the air, and the workers were complaining of respiratory problems. I used a PVC monitor to measure the concentration of PVC in the air, and I found that it was significantly higher than the allowable limit. I then worked with the plant manager to identify the source of the PVC emissions, and we were able to implement measures to reduce the emissions and protect the workers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for PVC Monitor (Polyvinyl Chloride Monitor).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the PVC Monitor (Polyvinyl Chloride Monitor)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The PVC Monitor (Polyvinyl Chloride Monitor) is responsible for monitoring and maintaining the PVC manufacturing process to ensure the production of high-quality PVC products. Key job responsibilities include:

1. Production Monitoring

Monitor the PVC manufacturing process, including raw material preparation, extrusion, and finishing, to ensure compliance with specifications and quality standards.

- Inspect raw materials for quality and quantity.

- Monitor extrusion and finishing processes to ensure product specifications are met.

2. Quality Control

Conduct regular quality control checks on PVC products to ensure they meet customer requirements and industry standards.

- Perform physical and chemical tests on PVC samples to assess product quality.

- Identify and troubleshoot quality issues in the production process.

3. Equipment Maintenance

Maintain and calibrate equipment used in the PVC manufacturing process to ensure accuracy and reliability.

- Perform regular maintenance tasks on extrusion machines, finishing equipment, and testing instruments.

- Troubleshoot and resolve equipment malfunctions to minimize downtime.

4. Process Improvement

Continuously monitor and evaluate the PVC manufacturing process to identify areas for improvement.

- Analyze production data to identify process bottlenecks and inefficiencies.

- Implement process improvements to increase efficiency and reduce production costs.

Interview Tips

To ace the PVC Monitor interview, candidates should prepare thoroughly and demonstrate their knowledge and skills in the following areas:

1. Technical Expertise

In-depth understanding of PVC manufacturing processes, including extrusion, finishing, and quality control.

- Highlight your experience in monitoring and controlling PVC production processes.

- Discuss your knowledge of PVC product specifications and quality standards.

2. Quality Control Skills

Proven ability to conduct quality control tests and analyze results to ensure product compliance.

- Emphasize your understanding of PVC testing methods and the interpretation of test results.

- Provide examples of how you have identified and resolved quality issues in PVC production.

3. Equipment Maintenance Experience

Experience in maintaining and troubleshooting extrusion and finishing equipment used in PVC manufacturing.

- Describe your experience in maintaining and calibrating PVC processing equipment.

- Provide examples of how you have resolved equipment malfunctions and minimized downtime.

4. Process Improvement Aptitude

Ability to analyze production data, identify inefficiencies, and implement process improvements.

- Highlight your experience in analyzing production data and identifying areas for improvement.

- Discuss your involvement in implementing process improvements that have increased efficiency and reduced costs.

5. Problem-Solving Skills

Demonstrate strong problem-solving skills and the ability to identify and resolve issues quickly and effectively.

- Describe a challenging situation you faced in PVC production and how you resolved it.

- Emphasize your ability to think critically and find solutions to complex problems.

6. Communication Skills

Excellent communication and interpersonal skills to effectively interact with production teams, quality control personnel, and management.

- Highlight your ability to clearly communicate technical information to diverse audiences.

- Provide examples of how you have effectively communicated with production teams and resolved issues.

Next Step:

Now that you’re armed with the knowledge of PVC Monitor (Polyvinyl Chloride Monitor) interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for PVC Monitor (Polyvinyl Chloride Monitor) positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini