Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pump Station Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

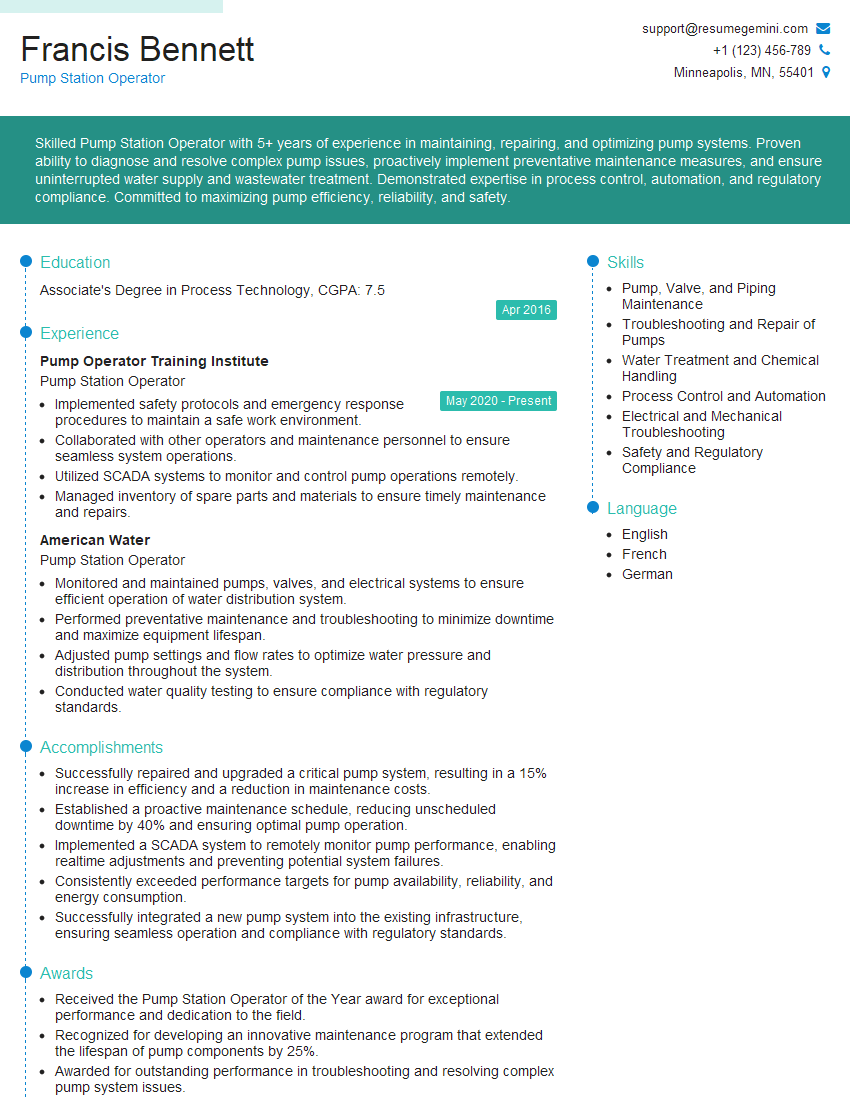

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pump Station Operator

1. What are the key responsibilities of a Pump Station Operator?

As a Pump Station Operator, I would be responsible for:

- Monitoring and controlling the operation of pumps, valves, and other equipment at the pump station.

- Ensuring that the pump station is operating efficiently and safely.

- Performing routine maintenance and repairs on equipment.

- Responding to emergencies and taking corrective action.

- Maintaining accurate records of pump station operations.

2. What is the difference between a centrifugal pump and a positive displacement pump?

Centrifugal Pump

- Uses centrifugal force to move fluid.

- Impeller rotates within a casing, creating a vacuum that draws fluid in and pushes it out.

- Suitable for low to medium viscosity fluids.

Positive Displacement Pump

- Traps fluid in a chamber and displaces it by the action of a piston, diaphragm, or gears.

- Can handle high-viscosity fluids and solids.

- Delivers a constant flow rate, even against high pressure.

3. What are the different types of pumps used in water distribution systems?

The different types of pumps used in water distribution systems include:

- Centrifugal pumps

- Positive displacement pumps

- Submersible pumps

- Booster pumps

- Variable speed pumps

4. What is the purpose of a variable speed pump?

Variable speed pumps are used to control the flow rate and pressure of water in a distribution system. They can be programmed to operate at different speeds depending on the demand for water, which can save energy and reduce wear and tear on equipment.

5. What are the most common problems that you have encountered as a Pump Station Operator?

Some of the most common problems that I have encountered as a Pump Station Operator include:

- Pump failures

- Valve failures

- Electrical problems

- Clogged pipes

- Power outages

6. How do you troubleshoot a pump that is not operating properly?

To troubleshoot a pump that is not operating properly, I would first check the power supply to make sure that it is getting electricity. I would then check the pump’s impeller to see if it is damaged or clogged. I would also check the pump’s bearings to see if they are worn or damaged. If I cannot find any obvious problems, I would consult the pump’s maintenance manual for further troubleshooting steps.

7. What are the safety precautions that you take when working at a pump station?

When working at a pump station, I always take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a hard hat.

- Be aware of the location of all emergency stop buttons.

- Never work on a pump that is operating.

- Lock out and tag out equipment before performing any maintenance or repairs.

- Follow all safety procedures and protocols.

8. What is the importance of preventive maintenance for pump stations?

Preventive maintenance is important for pump stations because it can help to prevent breakdowns, extend the life of equipment, and reduce operating costs. By performing regular maintenance tasks, such as lubricating bearings, changing filters, and inspecting pumps, we can identify and correct potential problems before they become major issues.

9. What are the different types of maintenance tasks that you perform on pumps?

The different types of maintenance tasks that I perform on pumps include:

- Lubricating bearings

- Changing filters

- Inspecting pumps for wear and tear

- Repairing or replacing damaged parts

- Overhauling pumps

10. What is your experience with SCADA systems?

I have experience with SCADA (Supervisory Control and Data Acquisition) systems in both my previous role as a Pump Station Operator and in my current role as a Maintenance Technician. I am familiar with the different components of a SCADA system, including the RTU (Remote Terminal Unit), the PLC (Programmable Logic Controller), and the HMI (Human Machine Interface). I am also familiar with the different types of SCADA software, such as Wonderware and Siemens WinCC.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pump Station Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pump Station Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pump Station Operators are responsible for the daily operations, maintenance, and repair of water pumping stations. The primary goal is to ensure that the water system is functioning smoothly, safely, and efficiently to meet the community’s water needs.

1. Monitoring and Control

Monitor pump station equipment, including pumps, motors, valves, and controls.

- Adjust pump settings to maintain system pressure and flow rates.

- Diagnose and troubleshoot equipment malfunctions and take corrective action.

2. Maintenance and Repair

Perform routine maintenance and repairs on pumps, motors, valves, and other equipment.

- Inspect and clean equipment, change filters, and lubricate moving parts.

- Repair or replace faulty components, such as seals, bearings, and electrical wiring.

3. Emergency Response

Respond to emergencies, such as power outages, pump failures, or water main breaks.

- Isolate and repair faulty equipment to minimize downtime.

- Coordinate with other utility crews and emergency response teams.

4. Record Keeping and Compliance

Maintain accurate records of equipment maintenance and repairs.

- Follow safety and environmental regulations.

- Prepare reports and documentation as required.

Interview Tips

To ace an interview for a Pump Station Operator position, candidates should prepare thoroughly and demonstrate their knowledge and skills relevant to the job. Here are some interview tips and preparation hacks:

1. Research the Company and Position

Familiarize yourself with the organization’s mission, values, and the specific requirements of the Pump Station Operator role. Check their website and any available company materials for insights.

- Tailor your resume and cover letter to highlight your qualifications and experience.

- Prepare questions to ask the interviewer about the company and the position, showing your interest and engagement.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and experience in pump station operations, maintenance, and repair. Provide specific examples of your work that demonstrate your abilities.

- Quantify your accomplishments whenever possible, using numbers or percentages to showcase your impact.

- Practice describing your problem-solving abilities and how you have successfully resolved technical issues.

3. Demonstrate Safety and Compliance Knowledge

Safety is paramount in pump station operations. Highlight your understanding of safety protocols and your commitment to adhering to them.

- Discuss your experience with lockout/tagout procedures and other safety measures.

- Explain your knowledge of environmental regulations related to water system operations.

4. Practice Common Interview Questions

Prepare for common interview questions that are relevant to the job, such as:

- Tell me about your experience in pump station operations.

- Describe a time when you successfully troubleshoot a pump or motor issue.

- How do you prioritize tasks and manage your time in a fast-paced environment?

5. Dress Professionally and Arrive on Time

Make a positive impression by dressing professionally and arriving on time for your interview. First impressions matter, so ensure you present yourself in a way that reflects the professionalism and responsibility required for the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pump Station Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.