Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Filter Filler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

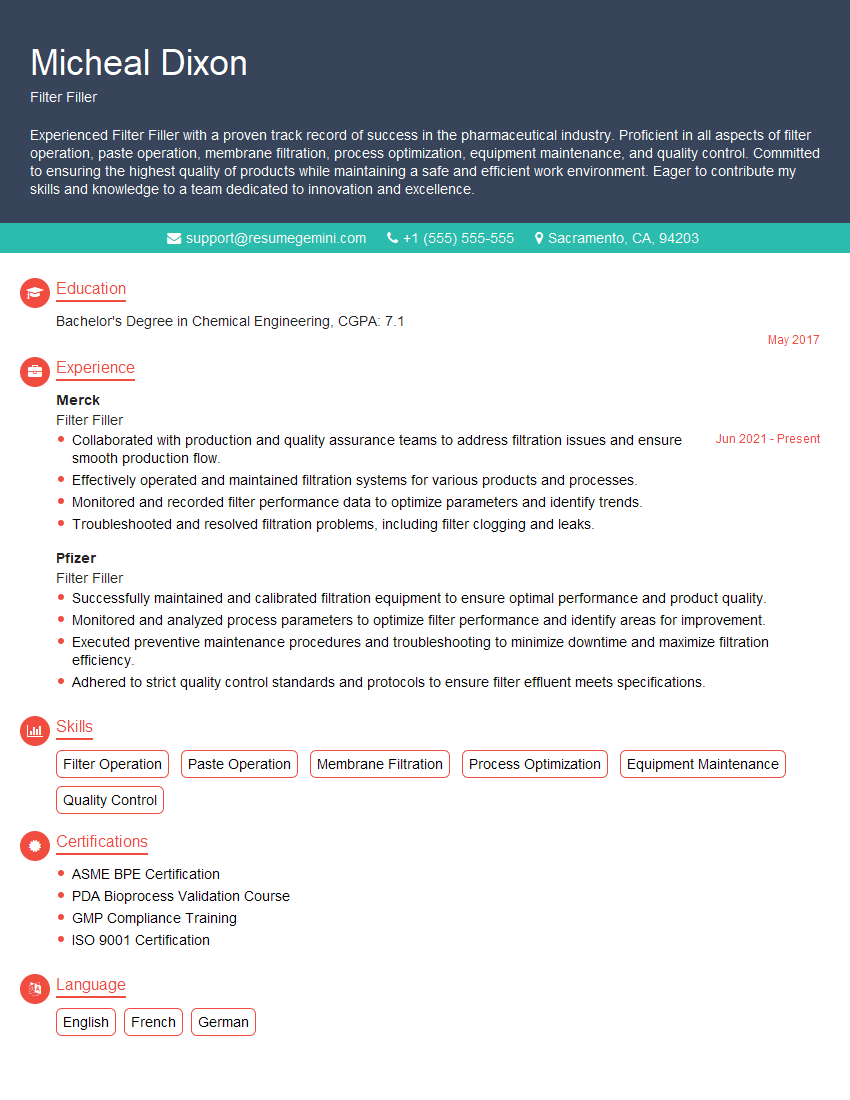

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filter Filler

1. Describe the process of filtering raw water to produce potable water.

The process of filtering raw water to produce potable water involves several key steps:

- Pre-treatment: Raw water is collected from sources like rivers, lakes, or groundwater and undergoes initial treatment to remove large particles, debris, and other contaminants.

- Coagulation and Flocculation: Chemicals are added to the water to cause impurities to clump together and form larger particles called flocs.

- Sedimentation: The flocs settle down by gravity in large basins or tanks, leaving cleaner water above.

- Filtration: The remaining water is passed through filter media, such as sand or activated carbon, to capture any remaining particles.

- Disinfection: The filtered water is disinfected using chemicals like chlorine or ozone to kill bacteria and viruses.

- Post-treatment: The water may undergo additional treatment steps, such as pH adjustment, to ensure its quality meets drinking water standards.

2. Explain the role of a filter press in the filtration process.

- A filter press is a device used in the filtration process to separate solids from liquids.

- It consists of a series of plates with filter cloths or membranes placed between them.

- The liquid is pumped into the press and forced through the filter cloths, leaving the solids trapped on the cloths.

- The plates are then separated, and the solids are removed.

Types of Filter Presses

- Recessed Chamber Filter Press: The filter cloths are recessed into the plates, creating a chamber where the solids accumulate.

- Membrane Filter Press: Uses membranes instead of filter cloths, providing higher filtration efficiency and reduced solids content in the filtrate.

3. Discuss the factors that influence the efficiency of a filtration system.

- Filter Media: The type and size of the filter media used play a critical role in determining the efficiency of the filtration process.

- Pressure: Higher pressure applied to the filter can increase the flow rate but may also reduce the efficiency of solids removal.

- Temperature: Viscosity of the liquid and filter media can be affected by temperature, impacting filtration efficiency.

- Cake Formation: Accumulation of solids on the filter media over time can create a filter cake that reduces flow rate and efficiency.

- Particle Size and Concentration: The size and concentration of particles in the liquid can affect how easily they are captured by the filter media.

- Chemical Compatibility: The compatibility of the filter media with the liquid and any chemicals used in the process is crucial to ensure optimal efficiency.

4. Describe the maintenance procedures for a filter system.

Regular maintenance is essential to ensure optimal performance of a filter system:

- Inspection: Regularly inspect the filter media, housing, and other components for any wear, damage, or blockages.

- Cleaning: Clean the filter media and housing using appropriate methods such as backwashing or chemical cleaning.

- Media Replacement: Filter media should be replaced periodically to maintain filtration efficiency.

- Calibration: Calibrate pressure gauges, flow meters, and other instruments to ensure accurate readings.

- Lubrication: Lubricate moving parts regularly to minimize friction and wear.

5. Explain the different types of filter media and their applications.

- Granular Media: Sand, gravel, and anthracite are commonly used granular media for water filtration, offering high flow rates and good solids removal.

- Activated Carbon: Used for removing organic contaminants, tastes, and odors from water.

- Membrane Filters: Provide high filtration efficiency and are used in applications such as ultrafiltration and reverse osmosis.

- Depth Filters: Made of materials like cellulose or fiberglass, these filters trap particles throughout their depth, providing higher solids loading capacity.

- Ceramic Filters: Highly porous ceramic materials used in applications requiring high temperature or chemical resistance.

6. Discuss the troubleshooting techniques for a filter system.

- Reduced Flow Rate: Check for clogged filter media, pressure drop, or insufficient pump capacity.

- Poor Filtration Efficiency: Inspect the filter media for damage, improper size, or saturation.

- Leaks: Check for damaged seals, gaskets, or cracks in the housing or piping.

- Contaminated Filtrate: Test the filtrate for breakthrough of contaminants, indicating potential filter failure or bypass.

- Excessive Pressure Drop: Clean the filter media or replace it if necessary.

7. Describe the safety precautions to be observed when operating a filter system.

- Wear appropriate personal protective equipment (PPE).

- Follow proper lockout/tagout procedures before performing maintenance.

- Ensure that the filter system is properly grounded.

- Handle chemicals used in the filtration process with care.

- Be aware of potential hazards such as slippery surfaces or confined spaces.

8. Explain the quality control measures for a filter system.

- Regular Testing: Conduct periodic testing of the filtrate to ensure it meets the required quality standards.

- Monitoring: Monitor key parameters such as pressure, flow rate, and temperature to track the performance of the filter system.

- Documentation: Maintain records of maintenance, testing, and any corrective actions taken.

- Audits: Conduct regular audits to assess the effectiveness of the quality control program.

9. Discuss the environmental implications of filter systems.

- Waste Generation: Filter media and solids captured during filtration need to be disposed of properly.

- Chemical Usage: Chemicals used in the filtration process, such as coagulants and disinfectants, can have environmental impacts.

- Energy Consumption: Pumping and filtration processes can consume energy.

- Water Conservation: Some filtration systems, such as reverse osmosis, can generate wastewater that needs to be managed responsibly.

10. Explain the role of a filter press in wastewater treatment.

- A filter press is used in wastewater treatment to dewater sludge, which is a semi-solid by-product of the treatment process.

- The sludge is pumped into the filter press, where it is forced through filter cloths or membranes.

- The solids are trapped on the cloths, while the water is removed.

- The dewatered sludge is then removed from the filter press and disposed of or further processed.

Benefits of Using Filter Presses in Wastewater Treatment

- High Solids Recovery: Filter presses can achieve high solids recovery rates, reducing the amount of waste generated.

- Reduced Disposal Costs: Dewatering sludge reduces its volume and weight, lowering disposal costs.

- Improved Sludge Handling: Dewatered sludge is easier to handle and transport.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filter Filler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filter Filler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Filter Filler is responsible for operating and maintaining filtration equipment used in various industrial and manufacturing processes. Their primary duties include:

1. Filter Operation

Loading and positioning filters into filtration equipment

- Starting and stopping filtration processes

- Monitoring filtration parameters, such as flow rate and pressure

2. Filter Maintenance

Cleaning and inspecting filters to ensure optimal performance

- Replacing filters when necessary

- Performing minor repairs and adjustments to filtration equipment

3. Quality Control

Sampling and testing filtrate to ensure product quality

- Inspecting filters for leaks and damage

- Maintaining records of filtration operations

4. Safety Compliance

Adhering to safety protocols and regulations

- Wearing appropriate personal protective equipment (PPE)

- Reporting any safety hazards or incidents

Interview Tips

To ace the interview for a Filter Filler position, it is crucial to prepare thoroughly. Here are some tips to help you make a strong impression:

1. Research the Company and Role

Familiarize yourself with the company’s products, services, and industry. Understand the specific responsibilities and requirements of the Filter Filler role.

- Visit the company’s website and social media profiles.

- Read industry publications and news articles.

2. Highlight Your Technical Skills

Emphasize your experience in operating and maintaining filtration equipment. Quantify your accomplishments with specific examples.

- Describe your knowledge of filtration principles and best practices.

- Share examples of how you have improved filtration efficiency or reduced downtime.

3. Demonstrate Quality Orientation

Showcase your commitment to product quality and process compliance. Provide examples of how you have ensured the integrity of filtration processes.

- Explain your understanding of quality control procedures and standards.

- Discuss your experience in sampling, testing, and reporting filtrate quality.

4. Emphasize Safety Awareness

Highlight your adherence to safety protocols and your understanding of potential hazards in a filtration environment.

- Describe your knowledge of industry safety regulations and PPE requirements.

- Share examples of how you have identified and mitigated safety risks.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Filter Filler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.