Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Concrete Pump Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

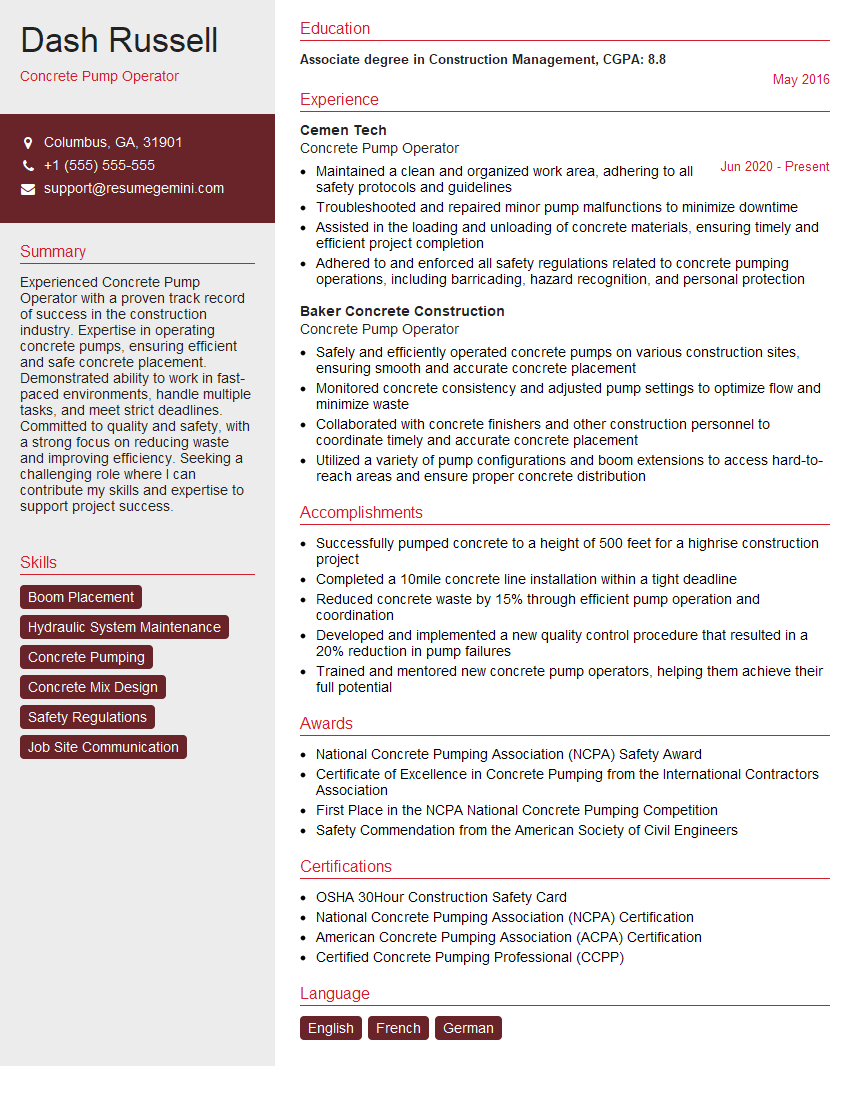

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Pump Operator

1. What are the different types of concrete pumps and their applications?

There are three main types of concrete pumps:

- Boom pumps: These pumps have a long, articulated boom that can reach up to 100 feet. They are used for placing concrete in hard-to-reach areas, such as the upper floors of buildings or the interiors of tunnels.

- Line pumps: These pumps are used to pump concrete through pipelines. They are typically used for long-distance pumping, such as when concrete is being pumped from a batch plant to a job site.

- Trailer pumps: These pumps are mounted on a trailer and can be easily transported from one job site to another. They are typically used for small to medium-sized concrete pours.

2. How do you operate a concrete pump?

Priming the pump

- Connect the pump to a water source and open the water valve.

- Start the pump and allow it to run until water flows out of the discharge hose.

- Close the water valve and open the concrete valve.

Pumping concrete

- Start the pump and allow it to run until concrete flows out of the discharge hose.

- Control the flow of concrete by adjusting the pump’s throttle.

- Stop the pump when the concrete has been placed.

3. What are the safety precautions that must be taken when operating a concrete pump?

The following safety precautions must be taken when operating a concrete pump:

- Wear appropriate safety gear, including a hard hat, safety glasses, and gloves.

- Never operate the pump in a confined space.

- Keep the pump away from electrical wires and other hazards.

- Never leave the pump running unattended.

- Be aware of the location of the discharge hose and never point it at anyone.

4. What are the common problems that can occur with concrete pumps and how do you troubleshoot them?

The following are some common problems that can occur with concrete pumps and how to troubleshoot them:

- The pump is not priming: Check the water supply and make sure that the water valve is open. If the pump still does not prime, there may be a problem with the pump’s suction line.

- The pump is not pumping concrete: Check the concrete supply and make sure that the concrete valve is open. If the pump still does not pump concrete, there may be a problem with the pump’s discharge line.

- The pump is leaking: Check the pump’s hoses and connections for leaks. If you find a leak, tighten the connection or replace the hose.

- The pump is overheating: Check the pump’s oil level and make sure that it is at the proper level. If the pump is still overheating, there may be a problem with the pump’s cooling system.

5. What is the difference between a concrete pump and a concrete mixer?

A concrete pump is used to pump concrete from one location to another. A concrete mixer is used to mix concrete ingredients together. Concrete pumps are typically used on large construction projects, while concrete mixers are used on smaller projects.

6. What are the different types of concrete mix designs and how do they affect the pumping process?

There are many different types of concrete mix designs, each with its own unique properties. Some of the most common mix designs include:

- Normal-weight concrete: This is the most common type of concrete mix design. It is made with Portland cement, sand, gravel, and water.

- Lightweight concrete: This type of concrete mix design is made with lightweight aggregates, such as expanded clay or shale. It is lighter than normal-weight concrete and is often used for applications where weight is a concern.

- High-strength concrete: This type of concrete mix design is made with high-strength cement and aggregates. It is stronger than normal-weight concrete and is often used for applications where strength is a concern.

7. What are the environmental regulations that apply to concrete pumping operations?

There are a number of environmental regulations that apply to concrete pumping operations. These regulations include:

- The Clean Water Act: This act regulates the discharge of pollutants into waters of the United States. Concrete pumping operations can generate wastewater that contains pollutants, such as sediment and concrete solids. This wastewater must be treated before it can be discharged into waters of the United States.

- The Clean Air Act: This act regulates the emission of air pollutants. Concrete pumping operations can generate air pollutants, such as dust and diesel exhaust. These pollutants must be controlled to meet the requirements of the Clean Air Act.

- The Resource Conservation and Recovery Act: This act regulates the generation, transportation, and disposal of hazardous waste. Concrete pumping operations can generate hazardous waste, such as used oil and solvents. This waste must be managed in accordance with the requirements of the Resource Conservation and Recovery Act.

8. What are the different types of concrete pumping equipment and how do they work?

There are a variety of different types of concrete pumping equipment, each with its own unique advantages and disadvantages. Some of the most common types of concrete pumping equipment include:

- Truck-mounted concrete pumps: These pumps are mounted on a truck chassis and are used for pumping concrete on large construction projects. Truck-mounted concrete pumps can be equipped with a variety of different booms, which allow them to reach different heights and distances.

- Trailer-mounted concrete pumps: These pumps are mounted on a trailer and are used for pumping concrete on smaller construction projects. Trailer-mounted concrete pumps are less expensive than truck-mounted concrete pumps, but they are also less versatile.

- Line pumps: These pumps are used to pump concrete through pipelines. Line pumps are typically used for long-distance pumping, such as when concrete is being pumped from a batch plant to a job site.

9. What are the factors that affect the cost of concrete pumping?

The cost of concrete pumping can vary depending on a number of factors, including:

- The size of the project: Larger projects will typically require more concrete and more pumping equipment, which will increase the cost of the project.

- The distance of the pump from the job site: The farther the pump is from the job site, the more time and fuel will be required to transport the pump, which will increase the cost of the project.

- The type of concrete being pumped: Some types of concrete are more difficult to pump than others, which can increase the cost of the project.

- The availability of concrete pumping equipment: The availability of concrete pumping equipment can also affect the cost of the project. If there is a high demand for concrete pumping equipment in your area, you may have to pay a premium to rent or purchase the equipment.

10. What are the career opportunities for concrete pump operators?

Concrete pump operators can work in a variety of different settings, including construction sites, concrete batch plants, and concrete pumping companies. Concrete pump operators can also work as independent contractors.

The career opportunities for concrete pump operators are good. The demand for concrete pumping services is expected to grow in the coming years, as more and more construction projects are being built. Concrete pump operators can earn a good salary and benefits, and they can have a long and rewarding career.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Pump Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Pump Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Concrete Pump Operator is responsible for the safe and efficient operation of the concrete pump and related equipment. This includes operating the pump, placing the concrete, and maintaining the equipment.

1. Operate the Concrete Pump

The operator must be able to operate the concrete pump according to the manufacturer’s instructions. This includes starting and stopping the pump, adjusting the flow rate, and troubleshooting any problems.

- Operate the pump controls to pump concrete to the desired location.

- Monitor the pump’s pressure and flow rate to ensure proper operation.

2. Place the Concrete

The operator must be able to place the concrete accurately and efficiently. This includes using the boom and/or hose to move the concrete to the desired location, and using the vibrator to consolidate the concrete.

- Use the boom and/or hose to place the concrete in the desired location.

- Use the vibrator to consolidate the concrete and remove any air pockets.

3. Maintain the Equipment

The operator must be able to maintain the concrete pump and related equipment. This includes performing routine maintenance tasks, such as greasing and oiling the pump, and troubleshooting and repairing any problems.

- Perform routine maintenance tasks, such as greasing and oiling the pump.

- Troubleshoot and repair any problems with the pump or related equipment.

4. Safety

The operator must be familiar with and follow all safety regulations related to the operation of the concrete pump. This includes wearing the proper safety gear, such as a hard hat, safety glasses, and gloves, and following all lockout/tagout procedures.

- Wear the proper safety gear, such as a hard hat, safety glasses, and gloves.

- Follow all lockout/tagout procedures.

Interview Tips

To ace the interview for a Concrete Pump Operator position, it is important to be prepared to answer questions about your experience and qualifications. You should also be familiar with the job responsibilities and be able to demonstrate your knowledge of concrete pumping equipment and safety regulations.

1. Research the Company

Before the interview, take some time to research the company you are applying to. This will help you to understand their business, their culture, and their specific needs. You can find information about the company on their website, in their annual report, and in news articles.

- Visit the company’s website to learn about their business, their products or services, and their culture.

- Read the company’s annual report to learn about their financial performance, their strategic goals, and their key initiatives.

- Search for news articles about the company to learn about their recent developments and their reputation in the industry.

2. Practice Answering Interview Questions

Once you have researched the company, you should practice answering interview questions. This will help you to feel more confident and prepared during the interview. You can practice answering questions with a friend, family member, or career counselor.

- Prepare for questions about your experience and qualifications.

- Practice answering questions about concrete pumping equipment and safety regulations.

- Research common interview questions and prepare your answers.

3. Dress Professionally

It is important to dress professionally for your interview. This shows the interviewer that you are serious about the position and that you respect the company.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your clothes are clean and pressed.

- Wear closed-toe shoes.

4. Be On Time

Punctuality is important for any job interview. Make sure to arrive at the interview on time, or even a few minutes early.

- Plan your route to the interview location in advance.

- Allow yourself extra time for traffic or unexpected delays.

- If you are running late, call the interviewer to let them know.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Concrete Pump Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.