Are you gearing up for an interview for a Booster Station Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Booster Station Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

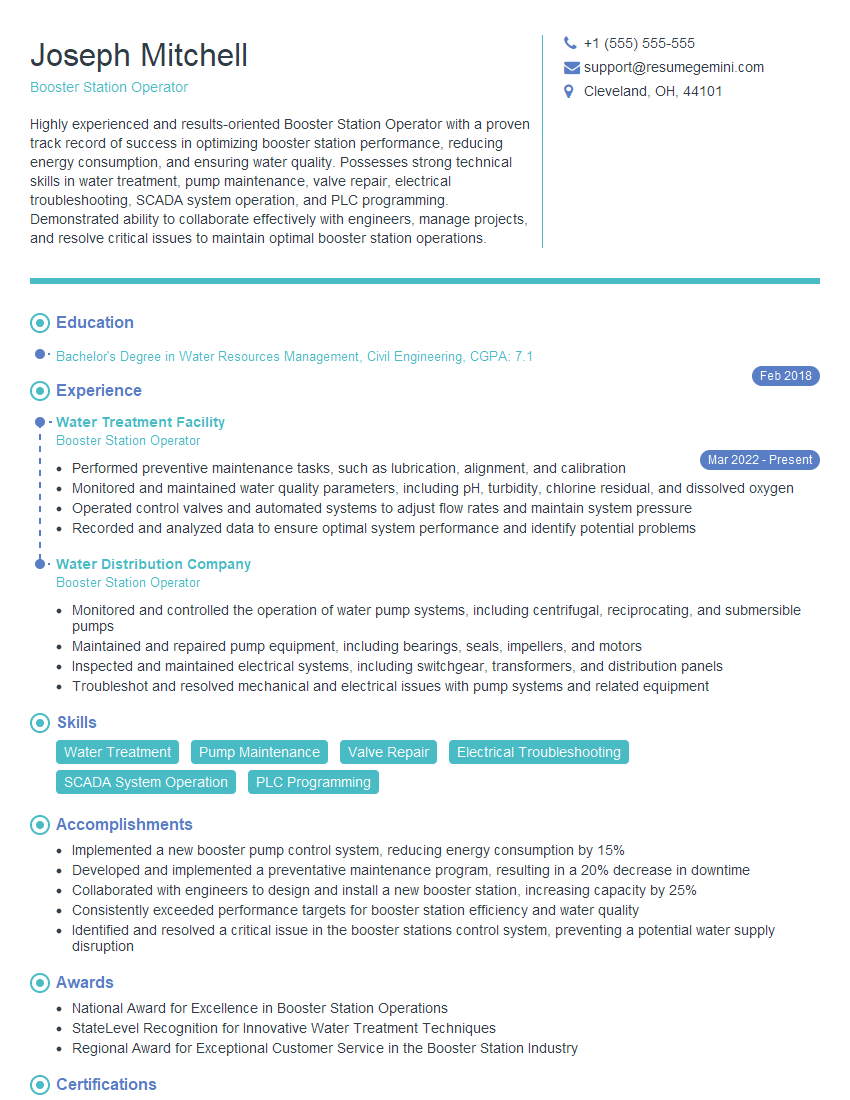

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Booster Station Operator

1. What are the key responsibilities of a Booster Station Operator?

As a Booster Station Operator, I would be responsible for:

- Monitoring and controlling the operation of booster pumps and associated equipment

- Maintaining and troubleshooting booster pumps and related systems

- Performing routine maintenance and inspections

- Responding to alarms and emergencies

- Maintaining accurate records and logs

2. What are the different types of booster pumps?

Positive displacement pumps

- Reciprocating pumps

- Rotary pumps

Centrifugal pumps

- Single-stage pumps

- Multi-stage pumps

3. How do you troubleshoot a booster pump that is not operating properly?

To troubleshoot a booster pump that is not operating properly, I would:

- Check the power supply

- Inspect the pump for any leaks or damage

- Verify that the pump is properly primed

- Check the discharge pressure

- Inspect the impeller and housing for any wear or damage

4. What are the safety precautions that must be taken when working with booster pumps?

When working with booster pumps, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE)

- Lock out and tag out the pump before performing any maintenance

- Be aware of the potential for high pressure and temperature

- Do not attempt to repair a pump that is under pressure

- Follow all manufacturer’s instructions

5. What are the different types of control systems used for booster pumps?

Manual control

- Operator manually starts and stops the pump

- Operator adjusts the pump speed and discharge pressure

Automatic control

- Pump is controlled by a programmable logic controller (PLC)

- PLC monitors system pressure and adjusts pump speed accordingly

6. What are the key performance indicators (KPIs) for a Booster Station Operator?

- Pump uptime

- Pump efficiency

- System pressure

- Energy consumption

- Maintenance costs

7. What are the latest trends in booster pump technology?

Variable speed drives (VSDs)

- VSDs allow pumps to operate at variable speeds

- This can improve pump efficiency and reduce energy consumption

Remote monitoring and control

- Pumps can now be monitored and controlled remotely

- This allows operators to respond to problems quickly and efficiently

8. What is the difference between a booster pump and a transfer pump?

- Booster pumps are used to increase the pressure of a fluid

- Transfer pumps are used to move a fluid from one location to another

9. What are the different types of piping materials used in booster pump systems?

Metallic piping

- Steel

- Stainless steel

- Copper

Non-metallic piping

- PVC

- CPVC

- PE

10. What are the different types of valves used in booster pump systems?

Check valves

- Prevent backflow

Gate valves

- Used to isolate sections of piping

Globe valves

- Used to control flow

Butterfly valves

- Used to isolate sections of piping

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Booster Station Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Booster Station Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Booster Station Operator is responsible for various crucial operations related to the efficient functioning of booster stations within the water distribution system. Their primary duties encompass maintaining and monitoring pumps, valves, and related equipment to ensure consistent water pressure and flow throughout the network.

1. System Monitoring and Control

Continuously monitors the status of booster station equipment using SCADA systems and other monitoring tools to identify any anomalies or performance issues.

- Adjusts pump settings and valve positions to maintain optimal water pressure and flow rates within the distribution network.

- Ensures that booster pumps are operating efficiently and are not subjected to excessive wear or damage.

2. Equipment Maintenance and Inspection

Conducts regular inspections and preventive maintenance on booster pumps, valves, piping, and other related components.

- Lubricates, cleans, and replaces worn parts as needed to ensure equipment longevity and reliability.

- Maintains accurate maintenance records and reports any issues or repairs to supervisors promptly.

3. Emergency Response and Troubleshooting

Responds promptly to emergencies or unexpected system failures, taking necessary actions to minimize disruptions.

- Troubleshoots and repairs equipment problems, using technical knowledge and experience to identify and resolve issues efficiently.

- Collaborates with other teams or external contractors as needed to ensure a timely and effective response.

4. Regulatory Compliance and Safety

Ensures compliance with all applicable regulations and safety protocols related to water distribution and booster station operations.

- Follows established safety procedures and wears appropriate personal protective equipment (PPE) during all tasks.

- Participates in safety training and maintains updated knowledge of industry best practices and regulations.

Interview Tips

To ace an interview for a Booster Station Operator position, it is essential to demonstrate a strong understanding of the job responsibilities and possess the necessary technical skills and experience. Here are some tips to help you prepare:

1. Research the Company and Industry

Gather information about the company’s water distribution system, the specific booster station you will be operating, and the industry as a whole. This knowledge will help you understand the context of the role and ask informed questions.

- Visit the company’s website and read industry publications to learn about their operations and current trends.

2. Highlight Your Technical Skills and Experience

Emphasize your knowledge of booster pumps, valves, piping systems, and water distribution principles. Provide specific examples of your experience in monitoring, maintaining, and troubleshooting these systems.

- Quantify your accomplishments whenever possible, using metrics such as reduced downtime or improved efficiency.

3. Demonstrate Your Problem-Solving Abilities

Interviewers want to know that you can handle unexpected situations and resolve technical issues effectively. Describe instances where you successfully diagnosed and repaired equipment problems or responded to emergencies.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide clear examples.

4. Show Your Commitment to Safety and Compliance

Water distribution systems are critical infrastructure, and safety is paramount. Highlight your understanding of safety protocols and your commitment to following them. Additionally, demonstrate your knowledge of regulatory requirements related to water quality and distribution.

- Provide examples of your experience in conducting safety inspections, maintaining equipment, and responding to emergencies.

5. Prepare for Common Interview Questions

Familiarize yourself with common interview questions related to Booster Station Operator positions. Practice your answers to questions about your experience, technical skills, problem-solving abilities, and commitment to safety.

- Consider preparing questions to ask the interviewer, which demonstrates your interest in the role and the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Booster Station Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Booster Station Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.