Are you gearing up for an interview for a Acetylene Gas Compressor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Acetylene Gas Compressor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

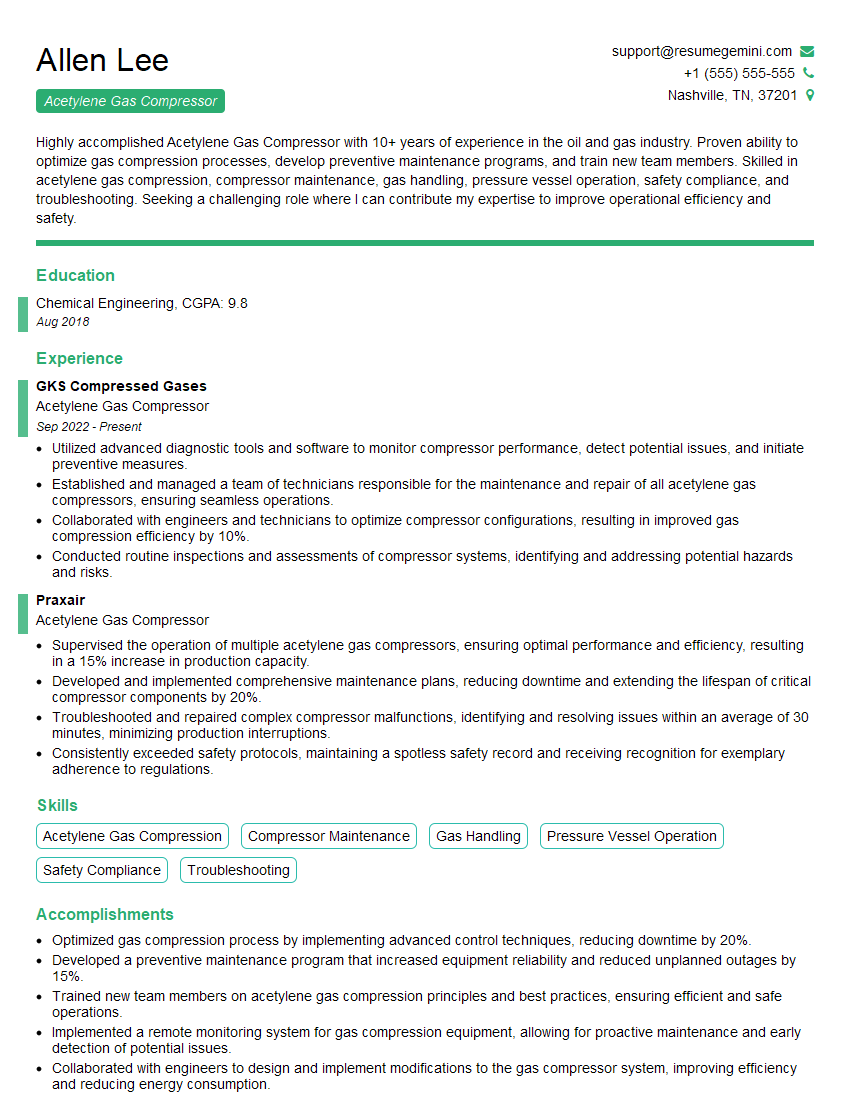

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Acetylene Gas Compressor

1. What are the key components of an acetylene gas compressor?

- Compressor housing

- Piston

- Cylinder

- Valves

- Lubrication system

- Cooling system

- Instrumentation and controls

2. Explain the working principle of an acetylene gas compressor.

Acetylene gas compressors use reciprocating piston or diaphragm to compress acetylene gas. The compressor takes in acetylene gas at low pressure and compresses it to a higher pressure.

Compression Cycle:

- The piston moves down, creating a vacuum in the cylinder.

- The intake valve opens, and acetylene gas flows into the cylinder.

- The piston moves up, compressing the acetylene gas.

- The discharge valve opens, and the compressed acetylene gas flows out of the cylinder.

3. What are the different types of acetylene gas compressors?

- Diaphragm compressors: Use a flexible diaphragm to compress the gas. They are oil-free and can handle corrosive gases.

- Piston compressors: Use a piston to compress the gas. They are more efficient than diaphragm compressors but require lubrication.

- Screw compressors: Use two intermeshing screws to compress the gas. They are oil-free and have a high compression ratio.

4. What are the factors to consider when selecting an acetylene gas compressor?

- Capacity (flow rate and pressure)

- Type of gas being compressed

- Operating environment

- Maintenance requirements

- Cost

5. What are the safety precautions to be taken when operating an acetylene gas compressor?

- Ensure proper ventilation to prevent gas accumulation.

- Use explosion-proof equipment.

- Avoid smoking or open flames near the compressor.

- Wear appropriate personal protective equipment (PPE).

- Follow manufacturer’s instructions and industry standards.

6. How do you troubleshoot common problems with acetylene gas compressors?

- Low discharge pressure: Check for leaks, clogged filters, or faulty valves.

- High discharge pressure: Check for overfilling, faulty pressure switch, or clogged discharge line.

- Excessive vibration: Check for loose bolts, worn bearings, or unbalanced components.

- Oil leaks: Check for damaged seals or gaskets.

- Overheating: Check for clogged cooling system, insufficient lubrication, or high ambient temperature.

7. What are the maintenance procedures for an acetylene gas compressor?

- Regularly check and tighten bolts.

- Replace filters and lubricate moving parts as per manufacturer’s recommendations.

- Inspect valves and seals for wear or damage.

- Clean the cooling system and check for leaks.

- Perform vibration analysis to detect potential problems.

8. What are the industry standards and regulations for acetylene gas compressors?

- NFPA 51: Standard for the Design and Installation of Oxygen-Fuel Gas Systems for Welding, Cutting, and Allied Processes

- OSHA 29 CFR 1910.102: Compressed Gas Safety

- ANSI/CGA G-1.1: Acetylene

9. What is the recommended storage pressure for acetylene gas?

Acetylene gas should be stored at a pressure not exceeding 15 psig (1 bar) in approved cylinders.

10. What are the potential hazards associated with acetylene gas?

- Explosions

- Fires

- Asphyxiation

- Health hazards (eye irritation, respiratory problems)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Acetylene Gas Compressor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Acetylene Gas Compressor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Acetylene Gas Compressor is responsible for the smooth operation and maintenance of acetylene gas compressors. These compressors are essential for a variety of industrial processes, including welding, cutting, and heating. The key job responsibilities of an Acetylene Gas Compressor include:

1. Compressor Operation

Operate and monitor acetylene gas compressors to ensure they are functioning properly.

- Start, stop, and adjust compressors as needed.

- Monitor compressor performance, including pressure, temperature, and flow rate.

2. Compressor Maintenance

Perform routine maintenance and repairs on acetylene gas compressors.

- Inspect and clean compressors regularly.

- Replace worn or damaged parts.

- Lubricate compressors as needed.

3. Safety Compliance

Follow all safety regulations and procedures when working with acetylene gas compressors.

- Ensure that compressors are properly ventilated.

- Wear appropriate personal protective equipment (PPE).

- Handle acetylene gas safely.

- Monitor fire risks.

4. Troubleshooting

Troubleshoot and resolve problems with acetylene gas compressors.

- Identify the source of problems.

- Repair or replace faulty parts.

- Make adjustments to compressor settings.

Interview Tips

To prepare for an interview for an Acetylene Gas Compressor position, it is important to research the company and the position itself. You should also practice answering common interview questions. Here are some tips to help you ace your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor. You can also learn about the specific position by reading the job description carefully.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, regardless of the position you are applying for. These questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

You can practice answering these questions by yourself or with a friend or family member. It is important to be prepared and confident in your answers.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment. You should also avoid wearing excessive jewelry or perfume.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, be sure to call or email the interviewer to let them know.

5. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and genuine, and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Acetylene Gas Compressor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!