Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tube Wrapper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tube Wrapper so you can tailor your answers to impress potential employers.

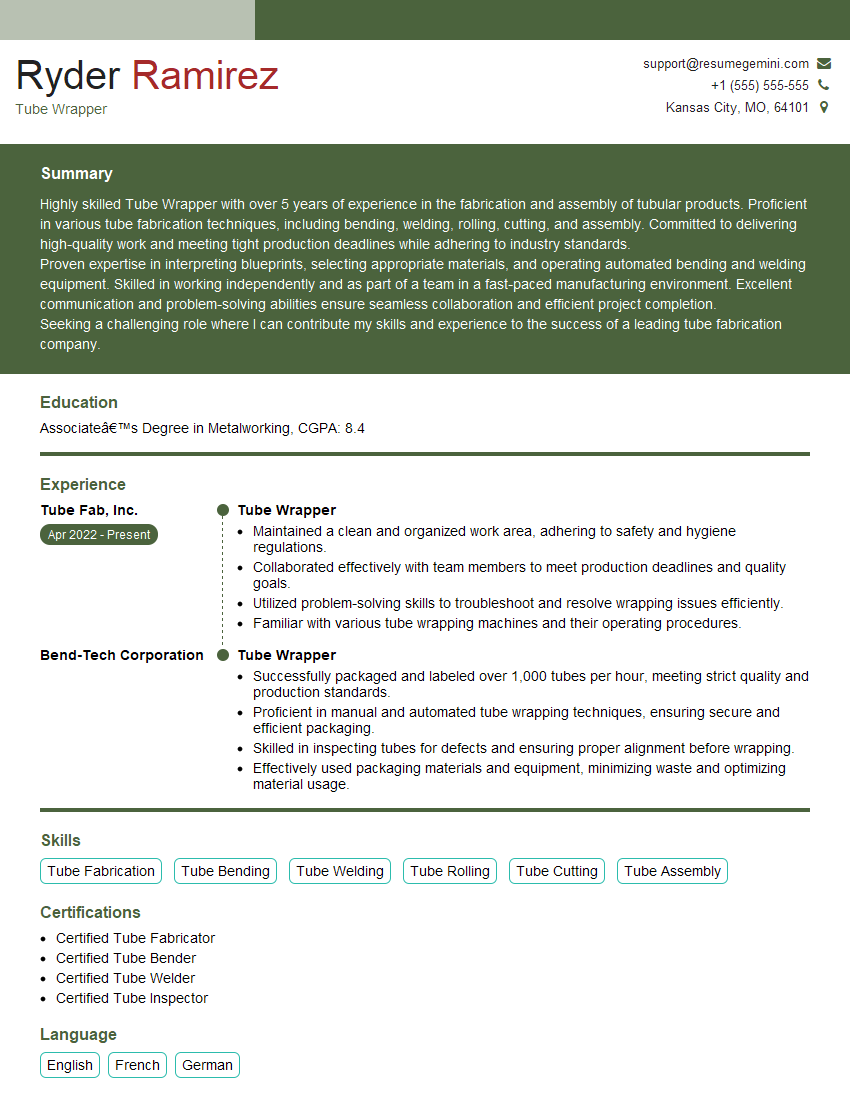

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Wrapper

1. Tell me about the different types of tube wrapping materials?

As a tube wrapper, I am familiar with a variety of tube wrapping materials, each with its own unique characteristics. Some of the most common types include:

- Corrugated cardboard: This is a strong and durable material that is often used for heavy-duty packaging. It is made from multiple layers of paper that are glued together, which gives it its strength and rigidity.

- Paperboard: This is a type of cardboard that is made from a single layer of paper. It is not as strong as corrugated cardboard, but it is less expensive and is often used for lighter-weight packaging.

- Plastic: Plastic is a lightweight and waterproof material that is often used for packaging food and other products. It is not as strong as cardboard, but it is more resistant to moisture and tearing.

- Metal: Metal is a strong and durable material that is often used for packaging heavy-duty products. It is more expensive than other materials, but it provides the best protection for products that are sensitive to damage.

2. What are the factors to consider when choosing a tube wrapping material?

Key factors to consider:

- The weight of the product

- The size of the product

- The shape of the product

- The environment in which the product will be stored or shipped

- The cost of the material

Additional considerations:

- The desired level of protection

- The sustainability of the material

- The aesthetics of the material

3. What are the different types of tube wrapping machines?

There are a variety of tube wrapping machines available, each with its own unique features and capabilities. Some of the most common types include:

- Manual tube wrapping machines: These machines are operated by hand and are typically used for small-scale packaging operations.

- Semi-automatic tube wrapping machines: These machines are partially automated and can be used for medium-scale packaging operations.

- Automatic tube wrapping machines: These machines are fully automated and can be used for large-scale packaging operations.

- Robotic tube wrapping machines: These machines are the most advanced type of tube wrapping machines and can be used for high-speed packaging operations.

4. What are the factors to consider when choosing a tube wrapping machine?

When choosing a tube wrapping machine, it is important to consider the following factors:

- The type of tube wrapping material that will be used

- The size and shape of the products that will be wrapped

- The speed at which the products need to be wrapped

- The level of automation that is required

- The cost of the machine

5. What are the safety precautions that should be taken when operating a tube wrapping machine?

When operating a tube wrapping machine, it is important to take the following safety precautions:

- Wear appropriate safety clothing, including gloves, safety glasses, and a hard hat.

- Make sure that the machine is properly grounded.

- Keep the work area clean and free of debris.

- Never operate the machine when it is not properly guarded.

- Follow all of the manufacturer’s instructions for operating the machine.

6. What are the different types of tube wrapping techniques?

There are a variety of different tube wrapping techniques, each with its own unique advantages and disadvantages. Some of the most common techniques include:

- Spiral wrapping: This technique involves wrapping the tube in a spiral pattern, starting from one end and working towards the other.

- Overlapping wrapping: This technique involves wrapping the tube in overlapping layers, starting from one end and working towards the other.

- Butt wrapping: This technique involves wrapping the tube in butted layers, starting from one end and working towards the other.

- Cross wrapping: This technique involves wrapping the tube in a cross pattern, starting from the center and working towards the ends.

7. What are the factors to consider when choosing a tube wrapping technique?

When choosing a tube wrapping technique, it is important to consider the following factors:

- The type of tube wrapping material that will be used

- The size and shape of the products that will be wrapped

- The desired level of protection

- The speed at which the products need to be wrapped

- The cost of the wrapping technique

8. What are the different types of tube wrapping equipment?

There are a variety of different types of tube wrapping equipment available, each with its own unique features and capabilities. Some of the most common types include:

- Manual tube wrappers: These wrappers are operated by hand and are typically used for small-scale packaging operations.

- Semi-automatic tube wrappers: These wrappers are partially automated and can be used for medium-scale packaging operations.

- Automatic tube wrappers: These wrappers are fully automated and can be used for large-scale packaging operations.

9. What are the factors to consider when choosing tube wrapping equipment?

When choosing tube wrapping equipment, it is important to consider the following factors:

- The type of tube wrapping material that will be used

- The size and shape of the products that will be wrapped

- The speed at which the products need to be wrapped

- The level of automation that is required

- The cost of the equipment

10. What are the benefits of using tube wrapping equipment?

There are many benefits to using tube wrapping equipment, including:

- Increased productivity

- Improved product quality

- Reduced labor costs

- Enhanced safety

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Wrapper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Wrapper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tube Wrappers are responsible for ensuring that products are properly wrapped and sealed for protection during shipping and handling.

1. Wrapping and Packaging

Wrap products using a variety of materials, including plastic wrap, paper, and bubble wrap.

- Follow specific wrapping procedures to ensure the product is protected from damage.

- Use proper labeling and identification techniques to ensure products are easily identified.

2. Quality Control

Inspect products for any defects or damage before wrapping.

- Reject or flag products that do not meet quality standards.

- Document any defects or damage found during the inspection process.

3. Machine Operation

Operate machines and equipment used for wrapping products.

- Set up and adjust machines according to product specifications.

- Monitor machine operation and make adjustments as needed.

4. Safety and Compliance

Follow all safety protocols and procedures.

- Wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area.

Interview Tips

Preparing for a Tube Wrapper interview can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take time to learn about the company’s history, products, and culture. Research the specific role and its responsibilities.

- This will help you understand the company’s needs and how your skills and experience align with the position.

- Example: You could visit the company’s website, read industry news, or connect with current or former employees on LinkedIn.

2. Practice Your Answers

Anticipate common interview questions and prepare your responses in advance. Practice answering questions out loud to improve your delivery and confidence.

- Consider questions about your experience, skills, and why you’re interested in the role.

- Example: You could practice answering questions such as “Tell me about your experience in wrapping and packaging.” or “Why are you interested in working as a Tube Wrapper?”

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that make you a suitable candidate for the role.

- Quantify your accomplishments whenever possible using specific examples and metrics.

- Example: You could say “In my previous role, I wrapped over 1000 products per day, ensuring they met all quality standards.”.

4. Be Enthusiastic and Professional

Show your enthusiasm for the role and the company. Dress professionally and maintain a positive and respectful demeanor throughout the interview.

- Your enthusiasm and professionalism will make a lasting impression on the interviewer.

- Example: You could express your interest in the company’s commitment to sustainability or the opportunity to contribute to their growth.

Next Step:

Now that you’re armed with the knowledge of Tube Wrapper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tube Wrapper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini