Are you gearing up for an interview for a Nuts and Bolts Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Nuts and Bolts Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

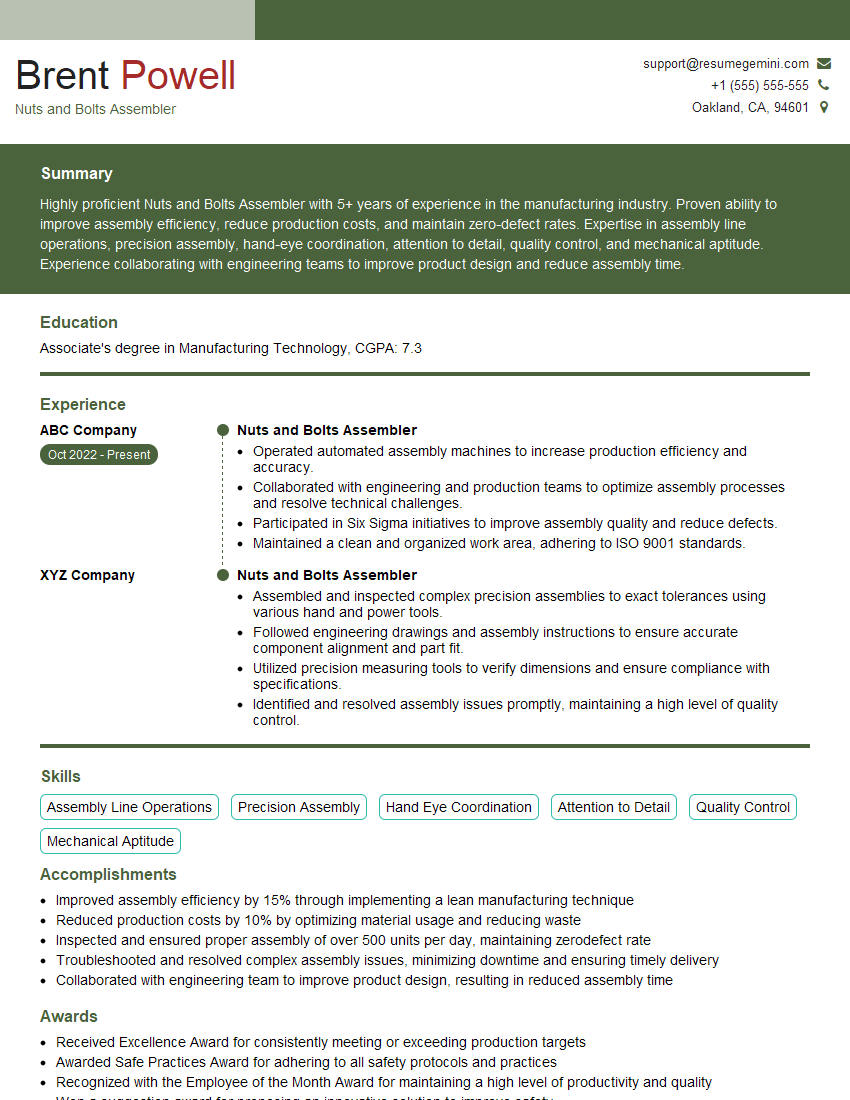

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nuts and Bolts Assembler

1. Describe the main principles of nut and bolt assembly?

- Identify the correct nuts and bolts for the assembly.

- Clean the mating surfaces of the nut and bolt to remove any dirt or debris that could interfere with a proper fit.

- Apply a thread-locking compound to the threads of the bolt to prevent it from loosening during use.

- Start the nut on the bolt by hand, then use a wrench to tighten it until it is snug.

- Continue to tighten the nut until it reaches the specified torque, as determined by the assembly instructions.

2. What are the different types of nut and bolt assemblies?

Nuts

- Hex nuts

- Square nuts

- Wing nuts

- Flange nuts

- Lock nuts

Bolts

- Carriage bolts

- Machine bolts

- Hex bolts

- Socket head bolts

- U-bolts

3. What are the most common problems that can occur during nut and bolt assembly?

- Cross-threading

- Stripped threads

- Loose nuts

- Broken bolts

- Corrosion

4. What are the proper techniques for tightening nuts and bolts?

- Use the correct tools for the job. A wrench or socket that is too large or too small can damage the nut or bolt.

- Tighten the nut or bolt until it is snug, but do not overtighten it. Overtightening can damage the nut or bolt.

- When tightening a nut or bolt on a critical application, use a torque wrench to ensure that it is tightened to the correct specification.

5. What are the safety precautions that should be taken when working with nuts and bolts?

- Wear eye protection when working with nuts and bolts.

- Do not use damaged nuts or bolts.

- Be aware of the potential for cross-threading and stripped threads.

- Do not overtighten nuts and bolts.

- Use the correct tools for the job.

6. What is the difference between a hex nut and a square nut?

- Hex nuts have six sides, while square nuts have four sides.

- Hex nuts are more common than square nuts.

- Hex nuts are typically used with a wrench, while square nuts can be used with a wrench or a socket.

7. What is the difference between a carriage bolt and a machine bolt?

- Carriage bolts have a round head and a square neck, while machine bolts have a hexagonal head and a threaded shank.

- Carriage bolts are typically used in wood applications, while machine bolts are typically used in metal applications.

- Carriage bolts are typically installed with a wrench, while machine bolts can be installed with a wrench or a socket.

8. What is the difference between a hex bolt and a socket head bolt?

- Hex bolts have a hexagonal head, while socket head bolts have a cylindrical head with a hexagonal recess.

- Hex bolts are typically used with a wrench, while socket head bolts are typically used with a socket.

- Socket head bolts are more compact than hex bolts, making them ideal for use in tight spaces.

9. What is the difference between a U-bolt and a J-bolt?

- U-bolts have two legs that are parallel to each other, while J-bolts have one leg that is bent at a 90-degree angle.

- U-bolts are typically used to secure pipes or other objects to a surface, while J-bolts are typically used to anchor structures to a concrete foundation.

- U-bolts are typically installed with a wrench, while J-bolts are typically installed with a hammer or a drill.

10. What is the difference between a nut and a washer?

- Nuts are used to secure bolts, while washers are used to distribute the load of a bolt or screw over a larger surface area.

- Nuts are typically made of metal, while washers can be made of metal, plastic, or rubber.

- Nuts are typically round, while washers can be round, square, or rectangular.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nuts and Bolts Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nuts and Bolts Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nuts and Bolts Assemblers are employed in the manufacturing industry and are responsible for joining and securing components using nuts, bolts, and other fasteners.

1. Assembling and Disassembling Equipment

Nuts and Bolts Assemblers primarily assemble and disassemble equipment using nuts, bolts, and related hardware. They work with various tools, such as screwdrivers, wrenches, pliers, and power tools.

- Follow assembly plans and drawings to ensure proper installation

- Use appropriate tools to tighten nuts and bolts

- Inspect completed assemblies to verify accuracy and functionality

2. Quality Assurance

Assemblers are also expected to maintain high standards of quality and accuracy in their work. This involves inspecting finished products for defects.

- Perform visual inspections for imperfections

- Test assembled components to ensure proper fit and function

- Adhere to established quality standards and specifications

3. Maintenance and Repair

Besides assembling and disassembling parts, Nuts and Bolts Assemblers may also be involved in basic maintenance and repair tasks.

- Repair damaged or defective assemblies

- Troubleshoot and resolve assembly issues

- Perform preventive maintenance to ensure equipment longevity

4. Safety Compliance

Safety is paramount in manufacturing environments. Assemblers must comply with all safety regulations and protocols.

- Wear appropriate safety gear (e.g., gloves, goggles)

- Follow safety procedures when operating tools and machinery

- Report any unsafe conditions or practices

Interview Tips

To ace the interview for a Nuts and Bolts Assembler position, candidates should prepare thoroughly and follow these tips:

1. Research the Company and Industry

Learn about the company, its products, and its manufacturing processes. Understanding the industry landscape will demonstrate your enthusiasm for the field.

- Visit the company website and social media pages

- Read industry news and articles

- Attend industry events if possible

2. Highlight Relevant Experience and Skills

Tailor your resume and cover letter to showcase your relevant skills and experience. If you have hands-on experience in assembly, machining, or a related field, emphasize those qualifications.

- Quantify your experience with specific accomplishments

- Use keywords from the job description in your application

- Practice describing your skills and experience in a clear and concise manner

3. Prepare for Technical Questions

In the interview, expect to encounter technical questions about assembly techniques, tools, and quality standards. Review common tools, fasteners, and materials used in assembly.

- Study basic mechanical principles and engineering drawings

- Research different types of assembly processes

- Practice troubleshooting hypothetical assembly issues

4. Emphasize Safety and Attention to Detail

Safety and attention to detail are crucial in assembly operations. Highlight your commitment to adhering to safety procedures and your ability to perform tasks with precision.

- Discuss your safety training and experience

- Explain how you ensure accuracy and quality in your work

- Provide examples of situations where your attention to detail prevented errors or accidents

5. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally for the interview and arrive on time. This demonstrates respect for the interviewer and the company.

- Wear clean and ironed business attire

- Be groomed and well-presented

- Plan your route to the interview location in advance to avoid delays

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Nuts and Bolts Assembler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Nuts and Bolts Assembler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.