Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Grain Sacker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Grain Sacker so you can tailor your answers to impress potential employers.

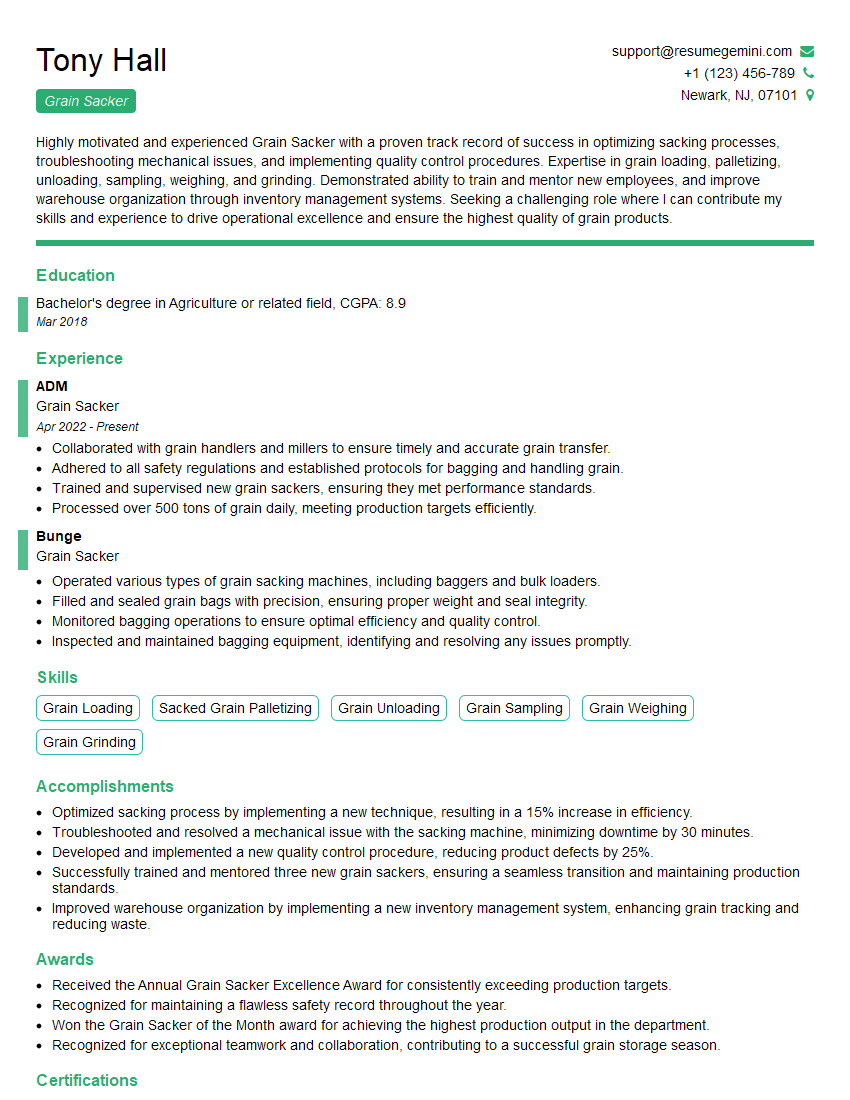

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grain Sacker

1. What is the purpose of a grain sacker machine?

To fill and seal grain sacks with a predetermined weight of grain

2. Explain the key components of a grain sacker machine and their functions.

- Hopper: Holds the grain and dispenses it into the sack

- Weighing system: Measures the grain weight and ensures the correct amount is dispensed

- Spout: Directs the grain flow into the sack

- Bag clamp: Secures the sack during filling and sealing

- Sealing system: Seals the filled sack to prevent spillage

3. What are the different types of grain sacks used in sacker machines?

Paper sacks: Low cost, biodegradable, but prone to tearing

Plastic sacks: Durable, reusable, but more expensive and less environmentally friendly

4. How do you adjust the sacker machine to accommodate different weights of grain?

- Calibrate the weighing system: Use a known weight to ensure accurate readings

- Adjust the filling rate: Modify the hopper speed or sprout opening to control the grain flow

- Monitor the sack weight: Use the weighing system to check the weight of filled sacks and make necessary adjustments

5. Describe the safety precautions you take when operating a grain sacker machine.

- Wear appropriate PPE: Gloves, safety glasses, dust mask

- Secure the sacks properly: Use the bag clamp to prevent sacks from falling

- Be aware of moving parts: Avoid hands or clothing getting caught

- Regularly inspect the machine: Check for any damage or malfunction

6. What is the maintenance schedule for a grain sacker machine?

- Daily: Clean the machine, check weighing accuracy

- Weekly: Lubricate moving parts, inspect seals

- Monthly: Calibrate the weighing system, perform thorough inspection

7. How do you identify and troubleshoot common problems with grain sacker machines?

- Sack overfilling: Check the weighing system and filling rate

- Sack underfilling: Calibrate the weighing system, adjust hopper speed

- Sealing issues: Inspect the sealing system, ensure proper bag clamping

- Machine jamming: Stop the machine, clear any blockages

8. Explain how you ensure the quality of filled grain sacks.

- Monitor sack weight: Use the weighing system to check the accuracy of each sack

- Inspect sacks for damage: Check for tears, punctures, or other defects

- Follow proper storage guidelines: Ensure sacks are stored in a dry, cool place to maintain grain quality

9. What is the importance of proper grain sacking in the grain industry?

Ensures accurate weight and quantity of grain, Protects grain from damage and contamination, Facilitates transportation and storage of grain

10. Describe any innovative technologies or practices in grain sacker machines that you are aware of.

- Automated sack handling systems: Use robotic arms or conveyors to handle sacks

- Integrated weighing and quality control systems: Provide real-time data on sack weight and quality

- Remote monitoring systems: Allow operators to monitor and control the machine remotely

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grain Sacker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grain Sacker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grain sackers are responsible for a variety of tasks related to the packaging and storage of grain. Their main duty is to operate machinery that fills and seals sacks with grain, ensuring the proper weight and quality of each sack.

1. Operate Grain Sacking Equipment

This involves setting up, calibrating, and operating sacking machines to fill and seal sacks with grain. They need to ensure that the machines are operating smoothly and efficiently to minimize downtime and maximize productivity.

- Monitor and adjust machine settings to maintain consistent sack weight and quality.

- Perform regular maintenance and troubleshooting on sacking equipment to identify and resolve any issues.

2. Inspect and Weigh Grain

Grain sackers are responsible for inspecting the grain before it is sacked to ensure it meets quality standards and does not contain foreign objects or contaminants. They also weigh the grain to ensure each sack contains the correct amount.

- Visually inspect grain for any signs of damage, pests, or foreign materials.

- Use scales to weigh grain and ensure each sack meets the specified weight requirements.

3. Manage Grain Storage

Grain sackers may also be responsible for managing the storage of grain sacks in warehouses or silos. They need to ensure that the sacks are stored properly to prevent damage and maintain the quality of the grain.

- Stack and arrange sacks in a way that optimizes space and maximizes airflow.

- Monitor grain storage conditions to ensure proper temperature and humidity levels are maintained.

4. Maintain a Clean and Safe Work Environment

Grain sackers are responsible for maintaining a clean and safe work environment to prevent accidents and preserve the quality of the grain.

- Clean and disinfect work surfaces and equipment to prevent contamination.

- Follow safety protocols to minimize the risk of accidents and injuries.

Interview Tips

To ace the interview for a Grain Sacker position, candidates should prepare thoroughly and demonstrate their knowledge of the role and the industry. Here are some tips to help candidates prepare:

1. Research the Company and the Role

Candidates should research the grain industry and the specific company they are applying to. This will give them a good understanding of the company’s values, goals, and the industry’s best practices.

- Visit the company’s website to learn about their history, products, and services.

- Read industry news and articles to stay updated on trends and best practices.

2. Practice Answering Common Interview Questions

Candidates should prepare answers to common interview questions such as “Why are you interested in this role?” or “What are your strengths and weaknesses?” Practicing their answers will help them feel more confident and articulate during the interview.

- Use the STAR method (Situation, Task, Action, Result) to structure their answers.

- Provide specific examples from their experience to demonstrate their skills and abilities.

3. Highlight Relevant Experience and Skills

Candidates should emphasize their relevant experience and skills in their resume and during the interview. This includes any experience operating grain sacking equipment, inspecting and weighing grain, or managing grain storage.

- Quantify their accomplishments with specific metrics to demonstrate the impact of their work.

- Use keywords from the job description to tailor their resume and cover letter.

4. Be Enthusiastic and Motivated

Grain sacking is a physically demanding job that requires candidates to be enthusiastic and motivated. During the interview, candidates should demonstrate their passion for the industry and their commitment to providing high-quality products.

- Express their interest in the role and the company during the interview.

- Ask questions about the company and the industry to show their engagement and enthusiasm.

Next Step:

Now that you’re armed with the knowledge of Grain Sacker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Grain Sacker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini