Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Egg Packer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

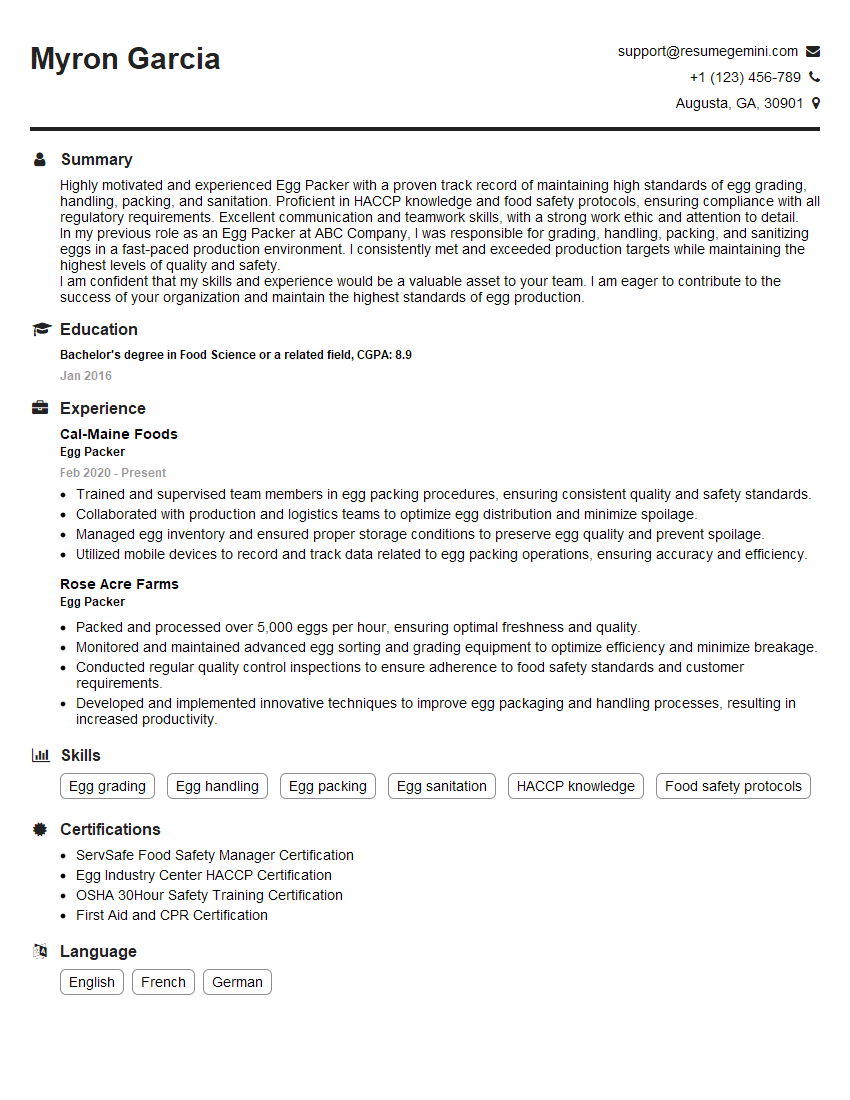

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Egg Packer

1. Explain the process of egg grading and packing?

Egg grading and packing is a crucial process that ensures the quality and freshness of eggs before they reach consumers. Here’s an overview of the steps involved:

- Receiving Eggs: Eggs are received from farms and undergo an initial inspection to check for any damage or cracks.

- Candling: Eggs are placed against a light source to examine their internal condition. Candling helps detect defects, such as air cells, blood spots, or other abnormalities.

- Grading: Based on the candling results, eggs are graded according to their quality. Common grades include AA, A, and B, with AA being the highest quality.

- Washing and Sanitizing: Eggs are washed and sanitized using approved chemicals to remove any surface contaminants or bacteria.

- Drying: The washed eggs are dried thoroughly to prevent the growth of bacteria.

- Packing: Graded eggs are carefully packed into cartons or other containers. Cartons are typically labeled with the grade, size, and date of packing.

- Storage: Packed eggs are stored under controlled temperature and humidity conditions to maintain their freshness until they are distributed to markets.

2. What are the different egg sizes and how do you determine their size?

- Jumbo: 30 ounces or more per dozen

- Extra Large: 27 ounces or more per dozen

- Large: 24 ounces or more per dozen

- Medium: 21 ounces or more per dozen

- Small: 18 ounces or more per dozen

- Peewee: Less than 18 ounces per dozen

Egg size is determined by weighing a sample of 30 eggs. The average weight of the sample determines the size category. Eggs are then packed accordingly.

3. What are the factors that affect the quality of eggs?

Several factors influence egg quality:

- Hen’s diet: A balanced diet provides the nutrients necessary for eggshell strength and egg quality.

- Hen’s health: Healthy hens lay eggs with fewer defects and higher nutritional value.

- Egg handling: Proper handling during collection, transportation, and storage prevents damage and maintains egg quality.

- Storage conditions: Eggs should be stored at a consistent temperature and humidity to preserve their freshness and prevent spoilage.

4. What are the different packaging materials used for eggs and their advantages and disadvantages?

- Cardboard Cartons:

- Advantages: Provide cushioning, protection, and ease of stacking.

- Disadvantages: Can be susceptible to moisture and breakage.

- Plastic Cartons:

- Advantages: Durable, transparent, and moisture-resistant.

- Disadvantages: Can be more expensive than cardboard cartons, not as biodegradable.

- Foam Trays:

- Advantages: Provide excellent cushioning and protection during transportation.

- Disadvantages: Can be bulky, not as reusable as cartons.

5. What are the safety precautions that need to be followed while working in an egg packing facility?

To ensure a safe work environment in an egg packing facility, the following precautions should be observed:

- Wear appropriate protective gear, including gloves, hairnets, and aprons.

- Maintain proper hygiene by washing hands frequently and using hand sanitizer.

- Handle eggs carefully to prevent breakage and potential exposure to bacteria.

- Be aware of potential hazards such as slippery floors, moving machinery, and sharp objects.

- Follow established safety protocols and report any unsafe conditions or incidents promptly.

6. What are the common challenges faced by egg packers and how do you overcome them?

Egg packers encounter various challenges:

- Egg quality maintenance: Ensuring the eggs remain fresh and of high quality throughout the packing process.

- Equipment malfunction: Dealing with unexpected equipment breakdowns that can disrupt production.

- Labor shortages: Finding and retaining skilled workers in a competitive labor market.

- Market fluctuations: Adapting to changing consumer demand and egg prices.

To overcome these challenges, egg packers implement strategies such as:

- Investing in quality control measures and training employees on proper egg handling techniques.

- Regularly maintaining and servicing equipment to prevent unexpected breakdowns.

- Offering competitive compensation and benefits packages to attract and retain employees.

- Monitoring market trends and adjusting production and sales strategies accordingly.

7. How do you ensure the traceability of eggs throughout the packing process?

Traceability is essential to track eggs from farm to consumer. Egg packers implement the following measures:

- Lot coding: Each batch of eggs is assigned a unique code that identifies the farm of origin, packing date, and other relevant information.

- Record keeping: Detailed records are maintained throughout the packing process, including the number of eggs received, graded, packed, and shipped.

- Electronic tracking systems: Some packers use advanced technology to track eggs electronically, providing real-time visibility into the supply chain.

8. What is your understanding of HACCP principles and how do you apply them in your work?

HACCP (Hazard Analysis and Critical Control Points) is a food safety system that identifies and controls potential hazards throughout the egg packing process. As an egg packer:

- I conduct a hazard analysis to identify potential risks, such as microbial contamination or physical hazards.

- I establish critical control points (CCPs) at specific stages in the process where hazards can be prevented or eliminated.

- I establish critical limits for each CCP to ensure that hazards are controlled effectively.

- I monitor CCPs regularly to ensure they are operating within critical limits.

- I implement corrective actions when CCPs deviate from critical limits.

- I verify the effectiveness of the HACCP system through regular audits and reviews.

9. How do you stay updated with the latest advancements in egg packing technology?

To stay informed about industry advancements:

- I attend industry conferences and workshops.

- I read trade publications and research papers.

- I network with other egg packers and equipment manufacturers.

- I explore new technologies and evaluate their potential benefits for our operation.

10. What are your goals for improving the efficiency and effectiveness of egg packing operations?

My goals for improving egg packing operations include:

- Automating processes: Exploring automation technologies to reduce manual labor and increase accuracy.

- Optimizing equipment: Identifying and implementing equipment upgrades to enhance efficiency and minimize downtime.

- Improving quality control: Implementing new techniques and technologies to further enhance egg quality and consistency.

- Enhancing traceability: Expanding traceability systems to provide greater transparency and traceability throughout the supply chain.

- Reducing waste: Identifying and implementing waste reduction measures to improve sustainability and profitability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Egg Packer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Egg Packer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Egg Packers are responsible for the efficient packing and handling of eggs. They ensure that eggs are packaged and stored in a way that maintains their quality and freshness. Their key responsibilities include:

1. Egg GraGrading and Sorting

Egg Packers are responsible for grading and sorting eggs by size, weight, and quality. They use a variety of tools and techniques to determine the quality of the eggs, including candling and weighing.

2. Packaging Eggs

Egg Packers are responsible for packaging eggs in a way that protects them from damage. They select the appropriate packaging materials, such as cartons or flats, and ensure that the eggs are packed securely.

3. Maintaining Egg Storage Areas

Egg Packers are responsible for maintaining egg storage areas in a clean and sanitary condition. They ensure that the eggs are stored at the proper temperature and humidity to maintain their freshness and quality.

4. Shipping Eggs

Egg Packers are responsible for shipping eggs to customers. They ensure that the eggs are packed securely and that they are shipped in a timely manner to maintain their quality and freshness.

Interview Tips

To prepare for an interview for an Egg Packer position, candidates should:

1. Research the Company

Candidates should research the egg-packing company thoroughly to understand its culture, values, and operations. This will enable them to tailor their answers to the specific needs of the company.

2. Prepare Examples

Candidates should prepare examples of their work experience that demonstrate their ability to perform the key responsibilities of an Egg Packer. These examples can be drawn from their previous employment or from volunteer or personal experiences.

3. Practice Answering Common Interview Questions

Candidates should practice answering common interview questions related to egg packing, such as:

- Tell me about your experience in egg grading and sorting.

- How do you ensure that eggs are packaged securely?

- What are your responsibilities for maintaining egg storage areas?

4. Dress Professionally

Candidates should dress professionally for their interview. This will demonstrate their respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Egg Packer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!