Are you gearing up for an interview for a Waste and Batting Waste Chopper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Waste and Batting Waste Chopper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

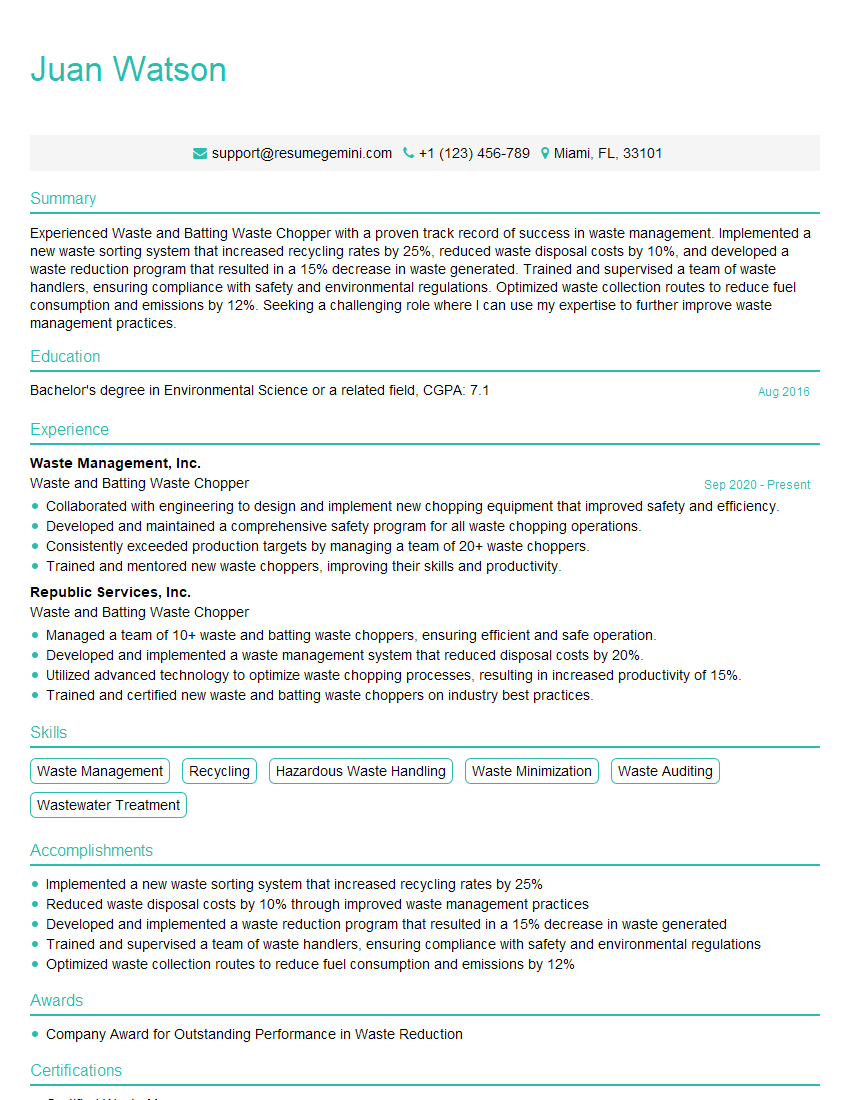

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Waste and Batting Waste Chopper

1. What are the different types of waste and batting waste choppers?

There are two main types of waste and batting waste choppers:

- Horizontal choppers: These machines have a horizontal cutting chamber and are used to chop large pieces of waste and batting waste into smaller pieces.

- Vertical choppers: These machines have a vertical cutting chamber and are used to chop smaller pieces of waste and batting waste into even smaller pieces.

2. What are the key features to consider when choosing a waste and batting waste chopper?

Factors to consider:

- Capacity: The capacity of a waste and batting waste chopper is measured in cubic yards per hour. The capacity of the chopper you choose will depend on the volume of waste and batting waste you need to chop.

- Power: The power of a waste and batting waste chopper is measured in horsepower. The power of the chopper you choose will depend on the type of waste and batting waste you need to chop.

- Cutting chamber: The cutting chamber of a waste and batting waste chopper is the area where the waste and batting waste is chopped. The size and shape of the cutting chamber will depend on the type of waste and batting waste you need to chop.

- Blades: The blades of a waste and batting waste chopper are the components that do the chopping. The type of blades you choose will depend on the type of waste and batting waste you need to chop.

Additional features:

- Safety features: Some waste and batting waste choppers come with safety features, such as interlocks and guards, to help prevent accidents.

- Ease of use: Some waste and batting waste choppers are easier to use than others. Consider the ease of use of the chopper when making your selection.

- Maintenance: Some waste and batting waste choppers require more maintenance than others. Consider the maintenance requirements of the chopper when making your selection.

3. What are the benefits of using a waste and batting waste chopper?

- Reduced waste volume: Waste and batting waste choppers can reduce the volume of waste and batting waste by up to 80%. This can save you money on waste disposal costs.

- Improved waste handling: Waste and batting waste choppers can make waste and batting waste easier to handle. This can improve the safety and efficiency of your waste handling operations.

- Environmental benefits: Waste and batting waste choppers can help to reduce the environmental impact of waste and batting waste. This is because chopped waste and batting waste is less likely to end up in landfills or incinerators.

4. What are the safety precautions that should be taken when using a waste and batting waste chopper?

- Always read and follow the manufacturer’s instructions.

- Never operate a waste and batting waste chopper without the proper safety guards in place.

- Keep hands and feet away from the cutting chamber.

- Do not overload the waste and batting waste chopper.

- Turn off the waste and batting waste chopper and disconnect the power before performing any maintenance or repairs.

5. What are the maintenance requirements for a waste and batting waste chopper?

- Regularly inspect the waste and batting waste chopper for wear and tear.

- Sharpen or replace the blades as needed.

- Lubricate the moving parts of the waste and batting waste chopper.

- Clean the waste and batting waste chopper after each use.

6. How do you troubleshoot a waste and batting waste chopper that is not working properly?

- Check the power supply to the waste and batting waste chopper.

- Check for any loose wires or connections.

- Inspect the blades for wear or damage.

- Check the cutting chamber for any blockages.

- Check the hydraulic system for any leaks or problems.

7. What is the difference between a waste chopper and a batting waste chopper?

- Waste choppers are designed to chop large pieces of waste into smaller pieces. They are typically used to process waste from industrial processes, such as manufacturing and construction.

- Batting waste choppers are designed to chop smaller pieces of batting waste into even smaller pieces. They are typically used to process batting waste from textile manufacturing.

8. What are the different types of blades that can be used in a waste and batting waste chopper?

- Straight blades are the most common type of blade used in waste and batting waste choppers. They are made of a hard material, such as steel, and are sharpened on one side.

- Serrated blades have a series of teeth along their cutting edge. They are more aggressive than straight blades and are used to chop tough materials, such as plastics and metals.

- Chipper blades are designed to chip large pieces of wood into smaller pieces. They are made of a thicker material than straight blades and have a more aggressive cutting edge.

9. How do you adjust the cutting chamber of a waste and batting waste chopper?

- The cutting chamber of a waste and batting waste chopper can be adjusted to change the size of the chopped material.

- To adjust the cutting chamber, loosen the bolts that hold the cutting chamber in place.

- Move the cutting chamber to the desired position and tighten the bolts.

10. How do you lubricate the moving parts of a waste and batting waste chopper?

- The moving parts of a waste and batting waste chopper should be lubricated regularly to prevent wear and tear.

- To lubricate the moving parts, apply a thin layer of grease to the bearings, gears, and other moving parts.

- Be careful not to over-lubricate the moving parts, as this can attract dirt and debris.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Waste and Batting Waste Chopper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Waste and Batting Waste Chopper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Waste and Batting Waste Choppers are responsible for chopping and disposing of waste and batting waste, ensuring a clean and sanitary work environment in various industrial and commercial settings, such as textile mills, recycling facilities, and waste management plants.

1. Waste Disposal

Collect and dispose of waste materials, including discarded fabrics, paper, plastic, and other organic matter.

- Operate waste disposal equipment, such as compactors and balers, to reduce waste volume and facilitate efficient disposal.

- Maintain a clean and organized waste disposal area, ensuring compliance with health and safety regulations.

2. Batting Waste Management

Handle and dispose of batting waste, a by-product of textile production, in a safe and environmentally friendly manner.

- Operate batting waste choppers to reduce the size of waste materials, facilitating disposal and recycling.

- Maintain and clean chopping equipment to ensure optimal performance and prevent contamination.

3. Equipment Maintenance

Perform routine maintenance and repairs on waste disposal and chopping equipment to ensure smooth operation and longevity.

- Inspect equipment for potential issues, such as wear and tear, leaks, or malfunctions.

- Lubricate, adjust, and calibrate equipment as needed to maintain optimal performance.

4. Safety and Compliance

Adhere to all safety protocols and regulations related to waste handling and disposal, ensuring the protection of personnel and the environment.

- Wear appropriate safety gear, such as gloves, masks, and protective clothing, when handling waste materials.

- Comply with environmental regulations and waste disposal guidelines to minimize environmental impact.

Interview Tips

To prepare for an interview as a Waste and Batting Waste Chopper, it is important to understand the key job responsibilities and highlight your relevant skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s culture, values, and specific waste management practices. Research the industry trends and best practices to demonstrate your knowledge and interest in the field.

- Visit the company’s website and social media pages to learn about their operations.

- Read industry publications and articles to stay updated on current waste management techniques.

2. Highlight Your Skills and Experience

Emphasize your proficiency in waste handling and disposal, including your ability to operate waste disposal equipment and manage batting waste. Showcase any previous experience in industrial or commercial waste management settings.

- Quantify your accomplishments whenever possible, using specific metrics and results.

- Provide examples of how you have maintained a clean and organized waste disposal area, ensuring compliance with health and safety regulations.

3. Demonstrate Your Commitment to Safety

Stress your understanding and commitment to safety protocols and regulations related to waste handling and disposal. Highlight your knowledge of personal protective equipment (PPE) and your adherence to environmental guidelines.

- Describe your experience in following safety protocols and preventing accidents in a waste management setting.

- Explain your understanding of the importance of waste segregation and proper disposal to minimize environmental impact.

4. Show Your Motivation and Enthusiasm

Convey your motivation for working as a Waste and Batting Waste Chopper and your enthusiasm for contributing to the efficient and sustainable management of waste materials.

- Explain your interest in the waste management industry and your desire to make a positive impact on the environment.

- Demonstrate your willingness to work in a physically demanding and hands-on environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Waste and Batting Waste Chopper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!