Are you gearing up for an interview for a Toggle Press Folder and Feeder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Toggle Press Folder and Feeder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

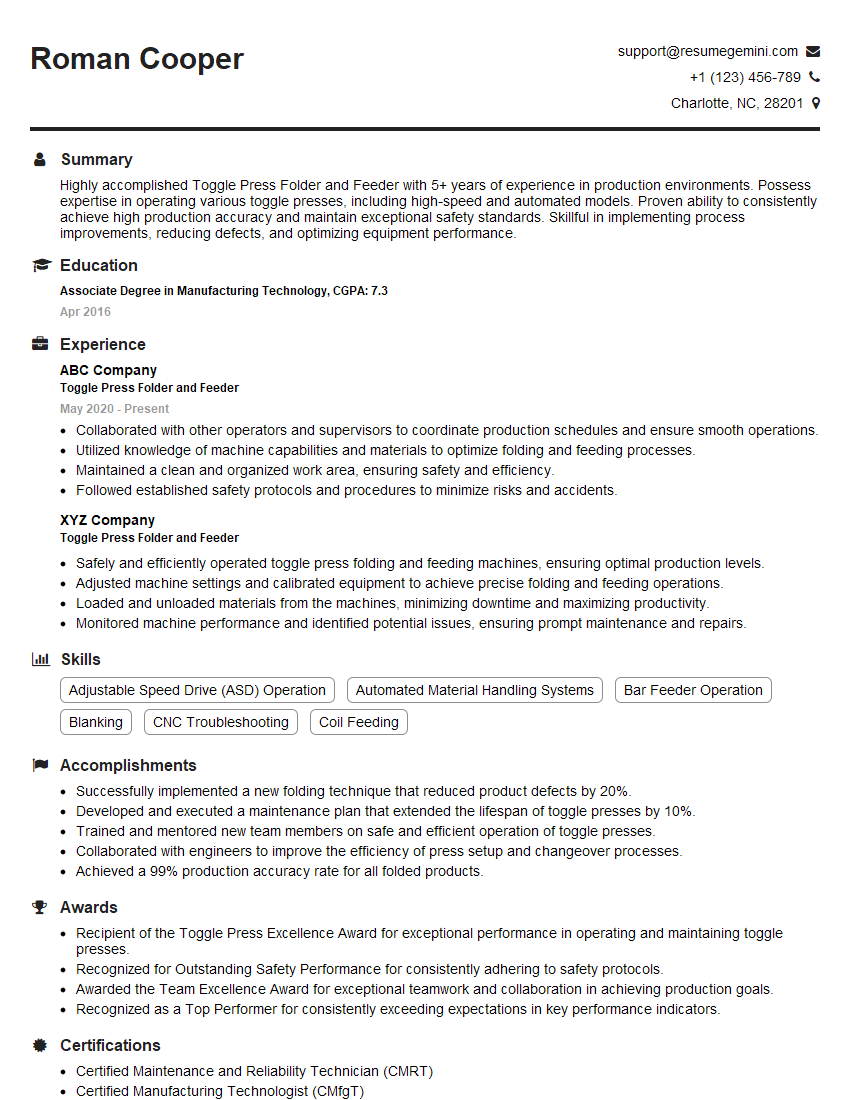

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Toggle Press Folder and Feeder

1. What are the different types of toggle presses and how are they used?

- Mechanical toggle presses: These are the most common type of toggle press and are used for a wide variety of applications. They are typically powered by an electric motor and use a mechanical linkage to create the toggling action.

- Hydraulic toggle presses: These presses use hydraulic pressure to create the toggling action. They are typically used for larger applications and can provide more force than mechanical toggle presses.

- Pneumatic toggle presses: These presses use compressed air to create the toggling action. They are typically used for smaller applications and are less powerful than mechanical or hydraulic toggle presses.

2. What are the different components of a toggle press folder and feeder?

subheading of the answer

- The frame is the main structural component of the press and supports the other components.

- The ram is the part of the press that moves up and down to apply pressure to the workpiece.

- The bed is the part of the press that supports the workpiece and provides a stable surface for the ram to press against.

- The feeder is the part of the press that automatically feeds the workpiece into the press.

- The folder is the part of the press that folds the workpiece after it has been pressed.

subheading of the answer

- The flywheel is the part of the press that stores energy and helps to maintain a constant speed during the pressing operation.

- The clutch is the part of the press that engages and disengages the flywheel from the ram.

- The brake is the part of the press that stops the ram at the end of the pressing operation.

3. How do you set up and operate a toggle press folder and feeder?

- First, the feeder is adjusted to the correct length and width of the workpiece.

- Next, the folder is adjusted to the correct angle and height.

- The workpiece is then placed into the feeder and the feeder is started.

- The workpiece is then fed into the press and the ram is lowered to apply pressure to the workpiece.

- Once the workpiece has been pressed, the ram is raised and the workpiece is ejected from the press.

4. What are some of the common problems that can occur with toggle press folders and feeders?

- The workpiece is not being fed into the press correctly.

- The workpiece is not being pressed correctly.

- The workpiece is not being folded correctly.

- The press is not operating properly.

5. How do you troubleshoot problems with toggle press folders and feeders?

- First, check the feeder to make sure that it is adjusted correctly and that the workpiece is being fed into the press correctly.

- Next, check the folder to make sure that it is adjusted correctly and that the workpiece is being folded correctly.

- If the workpiece is still not being pressed correctly, check the press to make sure that it is operating properly.

6. What are some of the safety precautions that should be taken when operating a toggle press folder and feeder?

- Always wear safety glasses when operating a toggle press folder and feeder.

- Never put your hands or fingers near the moving parts of the press.

- Always keep the work area clean and free of debris.

- Never operate the press if it is not in good working condition.

7. What are the different types of materials that can be used in a toggle press folder and feeder?

- Metals

- Plastics

- Paper

- Cardboard

- Wood

8. What are the different types of finishes that can be applied to a toggle press folder and feeder?

- Paint

- Powder coating

- Anodizing

- Plating

9. What are the different types of accessories that can be used with a toggle press folder and feeder?

- Dies

- Tooling

- Safety guards

- Automation systems

10. What are the advantages of using a toggle press folder and feeder?

- Toggle press folders and feeders are very versatile and can be used for a wide variety of applications.

- They are relatively easy to operate and maintain.

- They can be used to produce high-quality products.

- They are relatively affordable.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Toggle Press Folder and Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Toggle Press Folder and Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Toggle Press Folders and Feeders are responsible for operating and maintaining toggle presses used for folding and cutting metal sheets and coils. They ensure that the machines are running efficiently and safely, produce high-quality products, and meet production targets.

1. Machine Operation

Operate toggle presses to fold, cut, and shape metal sheets and coils according to specifications.

- Set up and adjust machines for different types of jobs.

- Load and unload materials into and out of the machines.

- Monitor the operation of the machines and make necessary adjustments to ensure proper functioning.

2. Quality Control

Inspect products to ensure that they meet quality standards.

- Identify and correct defects in products.

- Maintain records of quality inspections.

3. Maintenance and Troubleshooting

Perform routine maintenance and repairs on toggle presses and feeders.

- Lubricate and clean machines.

- Troubleshoot and repair mechanical and electrical problems.

4. Safety

Follow safety procedures and regulations to ensure a safe work environment.

- Wear appropriate safety gear.

- Operate machines safely.

- Report any unsafe conditions or practices.

Interview Tips

To ace an interview for a Toggle Press Folder and Feeder position, it is important to prepare thoroughly and demonstrate your knowledge, skills, and experience. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, products or services, and industry. Research the specific position and its responsibilities to understand the expectations of the role.

- Visit the company’s website and social media pages.

- Read industry articles and news to stay informed about current trends.

2. Highlight Your Experience and Skills

Emphasize your relevant experience in operating and maintaining toggle presses and feeders. Quantify your accomplishments and provide specific examples of your work. Showcase your skills in quality control, troubleshooting, and safety.

- Prepare examples of projects where you successfully folded or cut metal sheets to meet specifications.

- Describe how you have identified and resolved problems with toggle presses or feeders.

3. Demonstrate Your Safety Awareness

Safety is paramount in this role. Highlight your knowledge of safety procedures and regulations. Explain how you prioritize safety in your work and how you promote a safe work environment for yourself and others.

- Share examples of how you have followed safety protocols and identified potential hazards in the workplace.

- Discuss your understanding of industry safety standards and how you ensure compliance.

4. Be Prepared for Technical Questions

Expect technical questions related to toggle presses and feeders. Be prepared to discuss different types of presses, feeding mechanisms, and cutting tools. Show your understanding of the equipment and its operation.

- Review the basics of toggle press operations, including the principles of metal forming and cutting.

- Familiarize yourself with different types of feeding systems and how they are used.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Toggle Press Folder and Feeder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!