Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Thread Pulling Machine Attendant position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

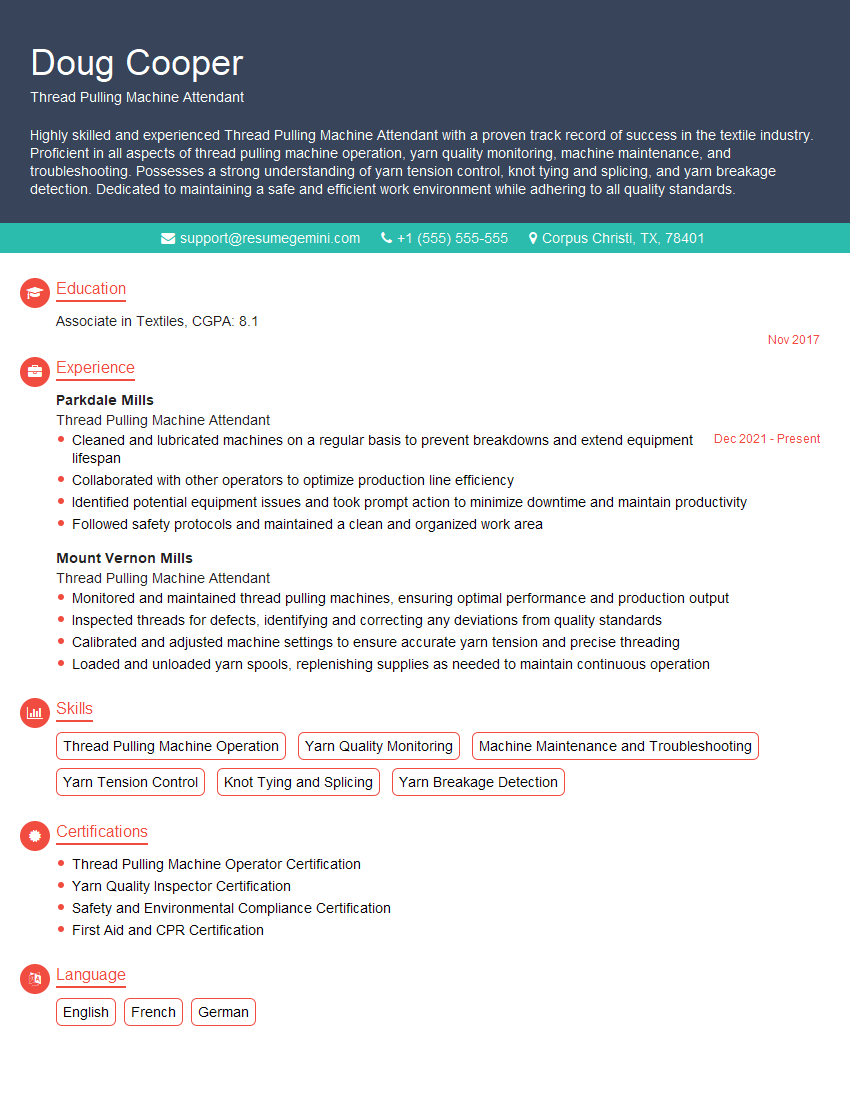

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Thread Pulling Machine Attendant

1. What are the primary responsibilities of a Thread Pulling Machine Attendant?

The primary responsibilities of a Thread Pulling Machine Attendant typically include:

- Loading and threading yarn or thread onto the machine

- Monitoring the machine’s operation and making adjustments as needed

- Inspecting the finished product for quality

- Troubleshooting and resolving any issues with the machine

- Cleaning and maintaining the machine

2. What is the difference between single-end and double-end thread pulling machines?

Single-end thread pulling machines process one thread at a time, while double-end thread pulling machines process two threads simultaneously.

Single-end machines are typically used for smaller diameter threads and for applications where high precision is required.

Double-end machines are typically used for larger diameter threads and for applications where speed is more important than precision.

3. What are the different types of thread tension devices used in thread pulling machines?

The different types of thread tension devices used in thread pulling machines include:

- Mechanical tensioners

- Pneumatic tensioners

- Electronic tensioners

Mechanical tensioners use a spring or weight to apply tension to the thread. Pneumatic tensioners use compressed air to apply tension to the thread. Electronic tensioners use a sensor to measure the tension of the thread and adjust it accordingly.

4. What are the common causes of thread breakage in thread pulling machines?

Common causes of thread breakage in thread pulling machines include:

- Incorrect thread tension

- Improper threading

- Worn or damaged machine parts

- Foreign objects in the machine

- Poor quality thread

5. How do you troubleshoot a thread pulling machine that is not producing good quality thread?

Checking the thread tension

First, check the thread tension to make sure it is set correctly. If the tension is too tight, the thread may break. If the tension is too loose, the thread may not be pulled through the machine properly.

Checking the threading

Next, check the threading to make sure the thread is threaded through the machine correctly. If the thread is not threaded correctly, it may not be pulled through the machine properly.

Inspecting the machine parts

Inspect the machine parts for any wear or damage. If any parts are worn or damaged, they may need to be replaced.

Cleaning the machine

Clean the machine to remove any foreign objects that may be causing the thread to break.

Trying a different type of thread

If the above steps do not resolve the issue, try using a different type of thread. Some types of thread are more prone to breakage than others.

6. How do you maintain a thread pulling machine?

To maintain a thread pulling machine, you should:

- Clean the machine regularly to remove any dust or debris

- Inspect the machine parts for any wear or damage

- Lubricate the machine regularly

- Calibrate the machine regularly

7. What safety precautions should be taken when operating a thread pulling machine?

When operating a thread pulling machine, you should take the following safety precautions:

- Wear appropriate safety gear, including safety glasses, gloves, and a lab coat

- Keep your hands and clothing away from moving parts

- Do not operate the machine if it is not properly guarded

- Be aware of the location of the emergency stop button

8. What are the different types of thread used in thread pulling machines?

The different types of thread used in thread pulling machines include:

- Natural fibers, such as cotton, wool, and silk

- Synthetic fibers, such as nylon, polyester, and rayon

- Metallic fibers, such as gold, silver, and aluminum

9. What are the different applications of thread pulling machines?

Thread pulling machines are used in a variety of applications, including:

- Textile manufacturing

- Medical device manufacturing

- Automotive manufacturing

- Aerospace manufacturing

10. What are the career advancement opportunities for Thread Pulling Machine Attendants?

Career advancement opportunities for Thread Pulling Machine Attendants include:

- Become a Thread Pulling Machine Operator

- Become a Supervisor

- Become a Manager

- Start your own business

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Thread Pulling Machine Attendant.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Thread Pulling Machine Attendant‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Thread Pulling Machine Attendant

1. Machine Operation and Maintenance

The Thread Pulling Machine Attendant is responsible for the efficient operation and maintenance of the thread pulling machine. This includes:

- Setting up and calibrating the machine according to specified parameters.

- Loading and unloading raw materials, such as thread spools and fabrics.

- Monitoring the machine’s operation to ensure smooth production.

- Performing preventive maintenance, such as cleaning and lubrication.

- Troubleshooting and resolving minor operational issues.

2. Quality Control and Inspection

The Attendant also plays a crucial role in ensuring product quality by:

- Inspecting the finished products for defects and measuring their dimensions.

- Maintaining quality control records and reporting any non-conformances.

- Identifying and implementing improvements to enhance product quality.

3. Production Monitoring and Reporting

The Thread Pulling Machine Attendant is responsible for:

- Monitoring production output and efficiency.

- Maintaining production logs and reporting on machine performance.

- Coordinating with other departments, such as planning and production control.

4. Health and Safety Compliance

The Attendant is also responsible for:

- Maintaining a clean and safe work environment.

- Following established safety protocols and procedures.

- Wearing appropriate personal protective equipment.

Interview Preparation Tips for Thread Pulling Machine Attendant

To ace your interview for a Thread Pulling Machine Attendant position, it’s essential to prepare thoroughly. Here are some tips to help you stand out:

1. Research the Company and Industry

Take the time to learn about the company’s history, products, and industry trends. This knowledge will demonstrate your interest in the company and help you understand the role’s context.

2. Review Key Job Responsibilities

Familiarize yourself with the key job responsibilities outlined above. Make notes on your experience and skills that align with these responsibilities.

3. Highlight Relevant Skills and Experience

During the interview, emphasize your experience in operating and maintaining thread pulling machines. Describe your abilities in quality control, production monitoring, and health and safety compliance.

4. Showcase Your Attention to Detail

Emphasize your attention to detail and your ability to identify and resolve minor operational issues. This is a crucial skill for ensuring product quality and machine efficiency.

5. Prepare Examples of Your Work

Bring examples of your work, such as quality control reports or improvement proposals, to demonstrate your skills and experience.

6. Ask Informed Questions

Prepare thoughtful questions about the company, the role, and the industry. Asking informed questions shows your interest and enthusiasm.

7. Dress Professionally and Arrive on Time

Make a good first impression by dressing professionally and arriving for your interview on time. This demonstrates your respect for the company and the hiring team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Thread Pulling Machine Attendant interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!