Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tailer Off position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

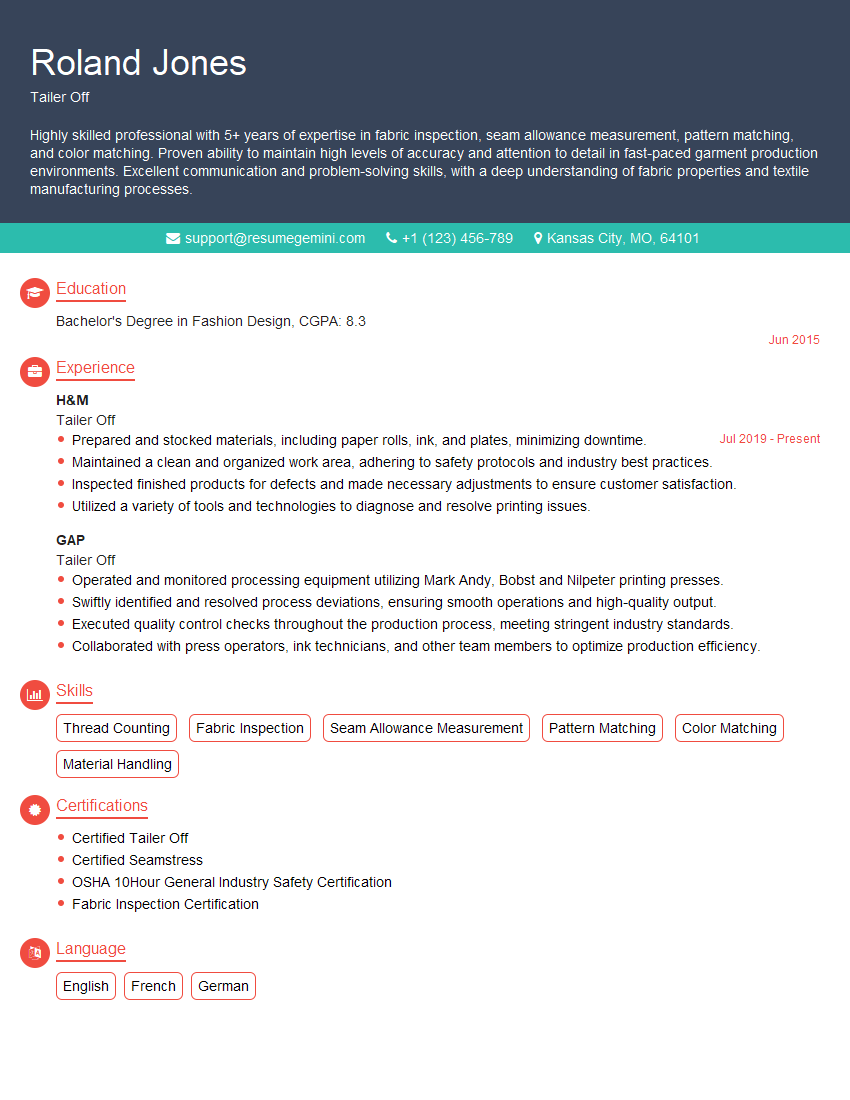

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tailer Off

1. Which safety measures do you follow while operating a forklift?

- Conduct a pre-shift inspection of the forklift, checking all systems for proper operation.

- Always wear a seatbelt when operating the forklift.

- Never exceed the designated speed limit for the work area.

- Be aware of your surroundings and watch for pedestrians and other vehicles.

- Never transport passengers on the forklift.

- Use a spotter when operating the forklift in areas with limited visibility.

- Never drive the forklift under the influence of drugs or alcohol.

2. How do you handle a load that is too heavy for the forklift?

Assess the situation

- Determine the weight of the load.

- Check the load against the forklift’s weight capacity.

- Consider the forklift’s stability and the load’s center of gravity.

Options for handling the load

- Reduce the weight of the load by breaking it into smaller pieces.

- Use a different forklift with a higher weight capacity.

- Use a counterweight or forklift attachment to increase stability.

- Get assistance from a coworker or supervisor.

3. How do you maintain a forklift battery?

- Check the battery level regularly and charge it as needed.

- Keep the battery terminals clean and free of corrosion.

- Add distilled water to the battery cells as needed.

- Avoid overcharging or undercharging the battery.

- Store the battery in a cool, dry place.

- Have the battery serviced by a qualified technician regularly.

4. What are the different types of forklift attachments and when are they used?

- Fork extensions: Used to extend the reach of the forks.

- Fork positioners: Used to adjust the forks to the correct width for the load.

- Side shifters: Used to move the forks sideways.

- Rotators: Used to rotate the load.

- Clamps: Used to hold the load securely.

- Push/pull attachments: Used to push or pull loads.

5. How do you troubleshoot a forklift that is not starting?

- Check the battery level and charge it if necessary.

- Check the battery terminals for corrosion and clean them if necessary.

- Check the fuses and replace any that are blown.

- Check the ignition switch and starter solenoid.

- Check the fuel level and add fuel if necessary.

- Check the air filter and replace it if necessary.

6. What are the different types of forklift tires and when are they used?

- Pneumatic tires: Used for outdoor use on rough terrain.

- Cushion tires: Used for indoor use on smooth surfaces.

- Solid tires: Used for heavy-duty applications and are puncture-proof.

- Non-marking tires: Used for applications where it is important not to damage the floor.

7. How do you perform a daily inspection of a forklift?

- Check the tires for wear and tear.

- Check the brakes for proper operation.

- Check the hydraulic system for leaks.

- Check the electrical system for loose wires.

- Check the mast for damage.

- Check the forks for damage.

8. What are the different types of forklift operator certifications and what do they mean?

- OSHA certification: Required for all forklift operators in the United States.

- ANSI certification: A voluntary certification that demonstrates a higher level of forklift operating skills.

- ITO certification: A certification that is specific to the operation of industrial trucks.

9. How do you handle a forklift in a confined space?

- Be aware of your surroundings and watch for obstacles.

- Drive slowly and carefully.

- Use a spotter if necessary.

- Avoid sudden movements.

- Be prepared to stop suddenly.

10. What are the different types of forklift load handling techniques?

- Single-load handling: Used for handling single items.

- Double-load handling: Used for handling two items at once.

- Block stacking: Used for stacking items in a block formation.

- Staggered stacking: Used for stacking items in a staggered formation.

- Interlocking stacking: Used for stacking items in an interlocking formation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tailer Off.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tailer Off‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tailer Offs are responsible for the safe and efficient operation of tailing systems, ensuring that the end product meets the desired specifications.

1. Equipment Operation

Operate and maintain tailing systems, including conveyors, pumps, and other associated equipment.

- Regularly inspect and clean conveyors.

- Troubleshoot and repair any malfunctions with equipment.

2. Tailings Management

Ensure that tailings are properly stored and disposed of.

- Monitor and record tailings levels.

- Coordinate with other departments to optimize tailings management.

3. Quality Control

Perform quality checks on tailings to ensure they meet environmental and safety standards.

- Collect and analyze samples.

- Generate and maintain quality control records.

4. Safety

Follow safety protocols and ensure a safe work environment for colleagues and visitors.

- Wear appropriate safety gear.

- Report any unsafe conditions or practices.

Interview Tips

Preparing for an interview can help candidates increase their chances of success. Here are some tips to help you ace your Tailer Off interview:

1. Research the Company and Position

Demonstrate your interest and enthusiasm by researching the company and the specific Tailer Off position you are applying for. This will help you understand the company’s culture, values, and the responsibilities of the role.

- Visit the company’s website and read about their mission, products, and services.

- Review the job description and identify the key skills and qualifications required.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to emphasize the skills and experience most relevant to the Tailer Off position. Use specific examples to demonstrate how you have successfully performed similar tasks in previous roles.

- Quantify your accomplishments whenever possible, using numbers and metrics to showcase your impact.

- Practice answering common interview questions related to your skills and experience.

3. Prepare for Technical Questions

Tailer Off interviews often include technical questions to assess your knowledge of equipment and safety protocols. Be prepared to discuss your experience with conveyor systems, pumps, and other relevant equipment.

- Review technical manuals and industry publications to enhance your knowledge.

- Consider preparing a portfolio or presentation to showcase your practical skills.

4. Demonstrate Safety Awareness

Safety is paramount in the Tailer Off role. During the interview, emphasize your understanding of and commitment to safety protocols. Highlight any relevant training or certifications you possess.

- Explain your approach to risk assessment and hazard identification.

- Share examples of how you have implemented safety measures in previous roles.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tailer Off, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tailer Off positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.