Are you gearing up for an interview for a Lathe Puller position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lathe Puller and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

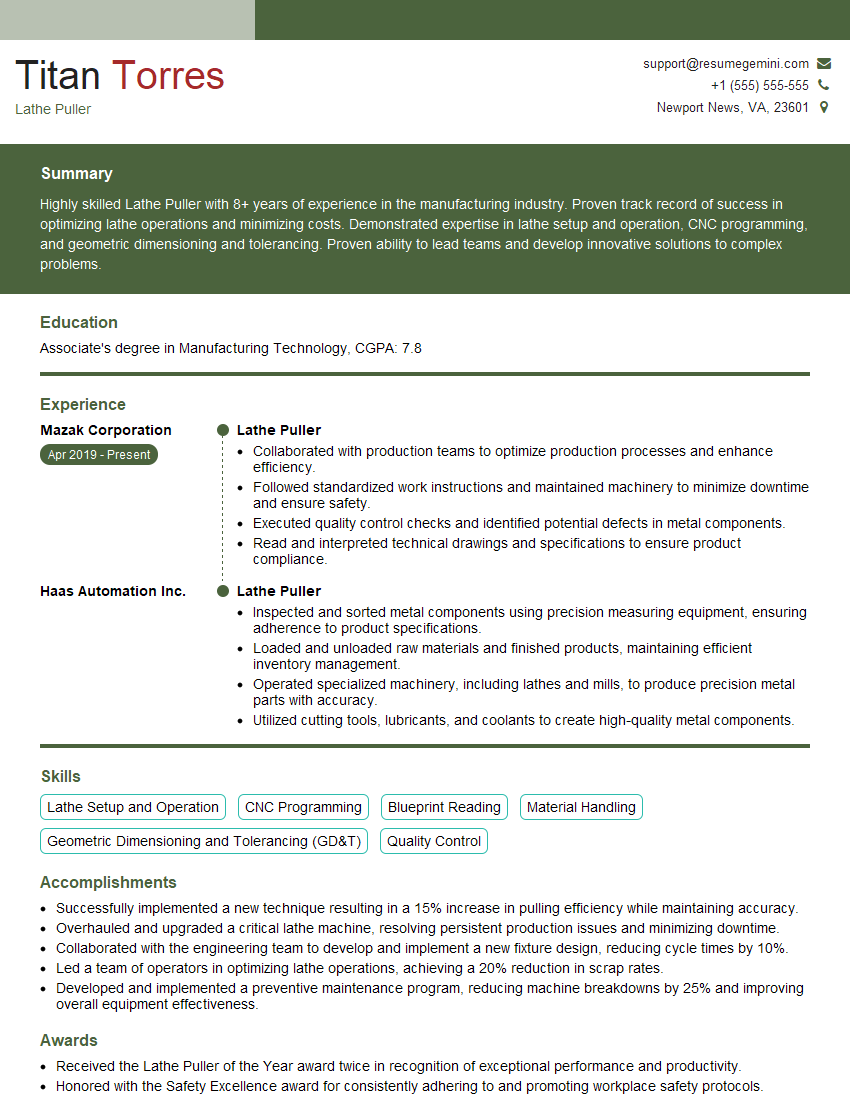

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lathe Puller

1. Describe the basic process of lathe pulling?

Lathe pulling involves removing or installing a wheel, gear, or bearing from a rotating shaft using a hydraulic puller.

- Preparation: Securely mount the part on the lathe.

- Puller Selection: Choose the appropriate puller size and capacity based on the component dimensions.

- Attachment: Attach the pulling arms to the component and the hydraulic ram to the puller frame.

- Pump Operation: Apply hydraulic pressure to the ram, which generates force to extract the component.

- Extraction: Monitor the pressure and ensure the component is removed safely and without damage.

- Checking: Verify that the component is completely removed and inspect for any damage or deformation.

2. What safety precautions should be taken when operating a lathe puller?

Prior to Use:

- Ensure the puller is rated for the intended use and load.

- Inspect the puller for any damage or defects.

- Wear appropriate safety gear, including gloves and safety glasses.

- Create a stable and level work area.

During Operation:

- Handle the puller carefully and avoid over-pressurization.

- Monitor the pressure gauge and discontinue use if the pressure becomes excessive.

- Never stand directly in line with the puller or the component being pulled.

- Use caution when applying force to avoid slips or accidents.

3. How do you determine the correct puller type and capacity for a specific application?

To determine the correct puller type and capacity, consider the following factors:

- Component Size and Weight: Determine the dimensions and weight of the component to be pulled.

- Shaft Diameter: Measure the diameter of the shaft where the component is mounted.

- Extraction Force: Calculate the estimated force required to extract the component.

- Pulling Method: Select a puller type that is compatible with the access and space limitations of the application.

- Manufacturer’s Recommendations: Refer to the manufacturer’s specifications for the puller’s maximum capacity and limitations.

4. Describe the different types of lathe pullers and their applications?

- Mechanical Pullers: Use a screw or lever mechanism to generate force, suitable for small- to medium-sized components.

- Hydraulic Pullers: Employ hydraulic pressure to generate high pulling force, ideal for heavy-duty applications.

- Jaw Pullers: Have serrated jaws that grip the component directly, suitable for removing gears, bearings, and other cylindrical parts.

- Bearing Pullers: Specifically designed to remove bearings from a shaft, featuring hooked arms that fit behind the bearing.

- Magnetic Pullers: Utilize electromagnets to generate strong pulling force, used for removing ferrous metal components.

5. How do you maintain a lathe puller for optimal performance?

- Regular Cleaning: Remove dirt, grease, and other contaminants from the puller.

- Lubrication: Apply lubrication to moving parts to ensure smooth operation and prevent wear.

- Inspection: Regularly check for any damage or wear, particularly to the jaws, arms, and hydraulic system.

- Pressure Testing: Periodically test the hydraulic system for proper pressure and functionality.

- Follow Manufacturer’s Instructions: Refer to the manufacturer’s manual for specific maintenance and storage recommendations.

6. What are some common problems that can occur when using a lathe puller and how do you troubleshoot them?

- Excessive Pressure: Monitor the pressure gauge and adjust the hydraulic pressure if it exceeds safe limits.

- Slipping Jaws: Ensure that the jaws are properly aligned with the component and that the clamping force is sufficient.

- Component Damage: Use the correct puller type and apply force gradually to avoid damaging the component.

- Hydraulic Leaks: Check for any leaks in the hydraulic system and tighten the connections or replace damaged components.

- Component not Removed: Verify that the puller is fully engaged with the component and that there are no obstacles preventing its removal.

7. Explain how to calculate the force required to extract a component using a lathe puller.

To calculate the force required, consider the following factors:

- Frictional Force: The force required to overcome the friction between the component and the shaft.

- Interference Fit: The force required to break the interference fit between the component and the shaft.

- Bearing Resistance: The force required to overcome the resistance of the bearing, if present.

- Safety Factor: An additional force to ensure the puller has sufficient capacity.

8. What are the advantages of using a lathe puller over other methods of component removal?

- Controlled Force: Allows for precise control of the applied force, reducing the risk of damage.

- Safety: Eliminates the need for manual handling and heavy lifting, minimizing the risk of injuries.

- Efficiency: Pullers provide a faster and more efficient method of component removal compared to traditional methods.

- Versatility: Lathe pullers can be used for a wide range of applications with different component sizes and shapes.

- Durability: Lathe pullers are designed to withstand heavy-duty use and provide long-term reliability.

9. Describe the role of a lathe puller in a machine shop and its significance in equipment maintenance.

In a machine shop, a lathe puller plays a critical role in equipment maintenance by:

- Disassembling Equipment: Used to remove components such as gears, bearings, and couplings for repair or replacement.

- Reassembling Equipment: Assists in reinstalling components after maintenance or upgrades.

- Preventing Damage: Provides a controlled method of component removal, minimizing the risk of damage to delicate parts.

- Maintaining Precision: Enables precise alignment and installation of components, ensuring optimal equipment performance.

- Improving Productivity: Reduces downtime by streamlining equipment maintenance and repair.

10. Discuss the importance of proper training and adherence to safety guidelines when using a lathe puller.

Proper training and adherence to safety guidelines are essential for ensuring the safe and effective operation of a lathe puller. This includes:

- Understanding the Principles: Thorough understanding of the lathe pulling process, component properties, and potential hazards.

- Safe Operating Techniques: Knowledge of proper puller selection, setup, and force application techniques.

- Hazard Awareness: Recognition and mitigation of potential hazards, such as hydraulic leaks, component failure, and excessive force.

- Personal Protective Equipment: Wearing appropriate safety gear, including gloves, safety glasses, and protective footwear.

- Emergency Procedures: Familiarization with emergency response protocols in case of accidents or equipment malfunctions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lathe Puller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lathe Puller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Lathe Puller is responsible for operating and maintaining lathes, which are machines that shape metal by rotating the workpiece against a cutting tool. The Lathe Puller’s key job responsibilities include:1. Operating Lathes

Lathe Pullers must be able to safely operate lathes to perform various machining operations, such as turning, facing, drilling, and boring. They must also be able to select and use the appropriate cutting tools and speeds for the job.

- Operate lathes to produce a variety of metal parts.

- Set up and adjust lathes for different machining operations.

- Select and use the appropriate cutting tools and speeds for the job.

- Monitor lathes during operation and make adjustments as needed.

- Identify and troubleshoot problems with lathes and take corrective action.

2. Maintaining Lathes

Lathe Pullers are also responsible for maintaining lathes to ensure that they are in good working condition. They must be able to perform basic maintenance tasks, such as cleaning, lubricating, and adjusting the lathes. They must also be able to identify and troubleshoot problems with the lathes and take corrective action.

- Clean and lubricate lathes regularly.

- Adjust lathes to ensure proper operation.

- Identify and troubleshoot problems with lathes and take corrective action.

- Maintain a clean and organized work area.

- Follow all safety procedures when operating and maintaining lathes.

3. Reading Blueprints and Technical Drawings

Lathe Pullers must be able to read blueprints and technical drawings to understand the specifications for the parts they are machining. They must also be able to use measuring tools to ensure that the parts are made to the correct dimensions.

- Read and interpret blueprints and technical drawings.

- Use measuring tools to ensure that parts are made to the correct dimensions.

- Follow all quality control procedures.

- Inspect finished parts to ensure that they meet specifications.

- Work independently and as part of a team.

4. Quality Control

Lathe Pullers must be able to follow quality control procedures to ensure that the parts they are machining meet the required specifications. They must also be able to inspect finished parts to ensure that they are free of defects.

- Follow all quality control procedures.

- Inspect finished parts to ensure that they meet specifications.

- Identify and correct any defects in finished parts.

- Maintain a clean and organized work area.

- Document all quality control activities.

Interview Tips

In order to ace the interview for a Lathe Puller position, it is important to be prepared to answer questions about your experience, skills, and knowledge. You should also be able to demonstrate your ability to work independently and as part of a team. Here are a few tips to help you prepare for your interview:1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, in industry publications, and on social media. You can also learn about the position by reading the job description and talking to people who work in the industry.

- Visit the company’s website to learn about their culture and values.

- Read industry publications to learn about the latest trends and technologies.

- Connect with people on LinkedIn to learn about their experiences working in the industry.

- Attend industry events to meet people and learn about job opportunities.

2. Practice Answering Interview Questions

One of the best ways to prepare for your interview is to practice answering common interview questions. This will help you to feel more confident and prepared during your interview. You can practice answering questions with a friend or family member, or you can use online resources to find practice questions and answers. Here are a few common interview questions that you may be asked:

- Tell me about your experience working with lathes.

- What are your strengths and weaknesses as a Lathe Puller?

- Why are you interested in working for our company?

- What are your salary expectations?

- Do you have any questions for me?

3. Dress Professionally and Arrive on Time

It is important to dress professionally for your interview and to arrive on time. This will show the interviewer that you are serious about the job and that you respect their time. You should also be prepared to answer questions about your experience, skills, and knowledge. If you are not prepared, you will likely not be able to ace the interview.

- Wear a suit or business casual attire.

- Arrive on time for your interview.

- Be prepared to answer questions about your experience, skills, and knowledge.

- Be polite and respectful to the interviewer.

- Follow up with the interviewer after the interview.

4. Be Yourself and Be Enthusiastic

It is important to be yourself and to be enthusiastic during your interview. The interviewer wants to get to know you and to see if you are a good fit for the team. If you try to be someone you’re not, the interviewer will be able to tell and will likely not be impressed. Instead, be genuine and be yourself. This will help you to make a good impression and to increase your chances of getting the job.

- Be yourself and be enthusiastic during your interview.

- Show the interviewer that you are interested in the job and that you are a good fit for the team.

- Be confident and be prepared to answer questions about your experience, skills, and knowledge.

- Ask questions about the company and the job to show that you are interested.

- Follow up with the interviewer after the interview to show that you are still interested in the job.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lathe Puller, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lathe Puller positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.