Feeling lost in a sea of interview questions? Landed that dream interview for Laminating Machine Feeder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Laminating Machine Feeder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

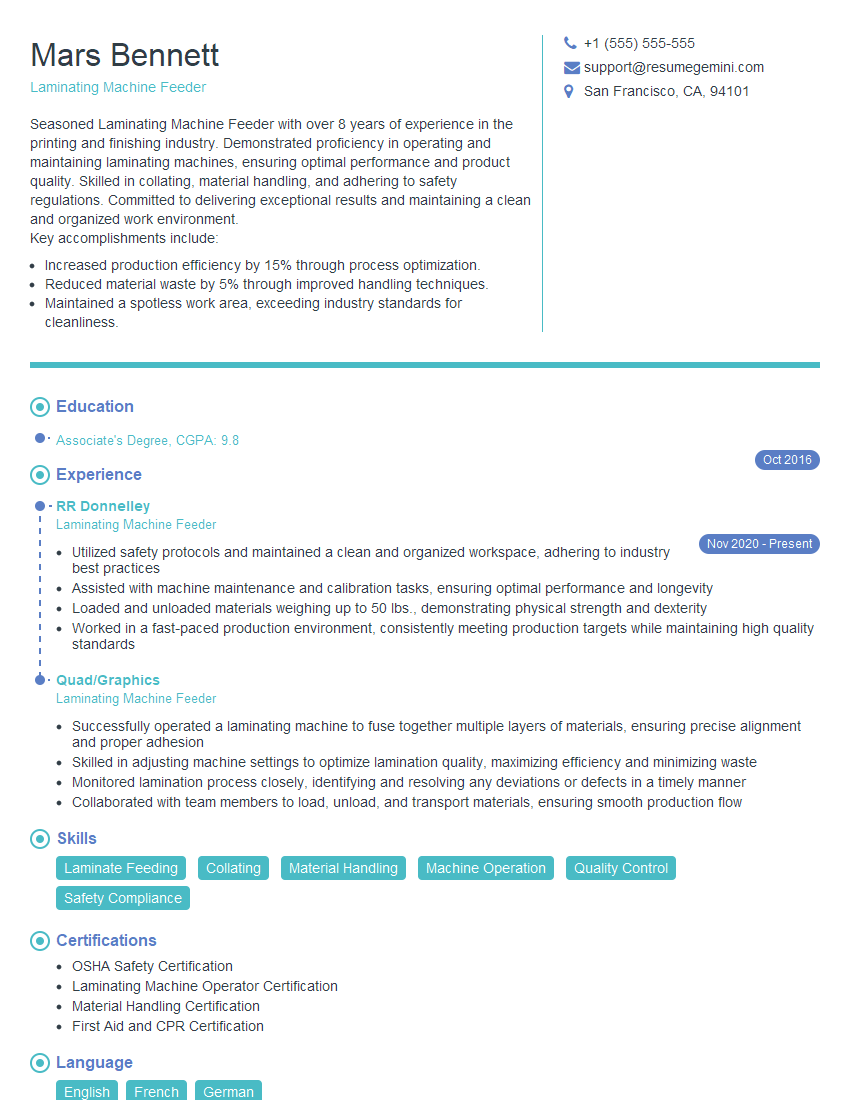

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Laminating Machine Feeder

1. What are the key responsibilities of a Laminating Machine Feeder?

The key responsibilities of a Laminating Machine Feeder include:

- Loading and unloading laminating films and materials onto the laminating machine.

- Adjusting the machine settings to ensure optimal lamination quality.

- Monitoring the lamination process and making necessary adjustments to ensure smooth operation.

- Inspecting the finished laminates for defects and ensuring they meet quality standards.

- Maintaining a clean and organized work area.

2. Describe the different types of laminating machines and their uses.

There are two main types of laminating machines: roll laminators and pouch laminators.

Roll laminators

- Use heat and pressure to bond a thin layer of plastic film to a document or other material.

- Typically used for large-scale lamination projects, such as posters, banners, and menus.

Pouch laminators

- Use pre-sealed plastic pouches to laminate documents and other materials.

- Smaller and more portable than roll laminators, making them ideal for small-scale projects.

3. How do you ensure the quality of the laminated products?

To ensure the quality of the laminated products, I:

- Inspect the materials before loading them into the machine.

- Calibrate the machine regularly to ensure accurate temperature and pressure settings.

- Monitor the lamination process and make adjustments as needed.

- Inspect the finished laminates for defects and reject any that do not meet quality standards.

4. What are the common problems that can occur during the lamination process and how do you troubleshoot them?

Some common problems that can occur during the lamination process include:

- Bubbles or wrinkles in the laminate: This can be caused by improper feeding of the materials or incorrect temperature settings. I would adjust the machine settings and ensure that the materials are fed smoothly.

- Laminate peeling off the material: This can be caused by insufficient pressure or adhesive failure. I would increase the pressure settings or replace the adhesive film.

- Laminate jamming in the machine: This can be caused by a mechanical issue or improper feeding. I would clear the jam and inspect the machine for any damage.

5. What are the safety precautions that should be followed when operating a laminating machine?

When operating a laminating machine, it is important to follow these safety precautions:

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep the work area clean and free of clutter.

- Do not touch the hot rollers of the machine.

- Unplug the machine when not in use.

6. How do you maintain a laminating machine?

To maintain a laminating machine, I perform the following tasks:

- Clean the machine regularly with a soft cloth and mild detergent.

- Lubricate the moving parts of the machine according to the manufacturer’s instructions.

- Calibrate the machine regularly to ensure accurate temperature and pressure settings.

- Inspect the machine for any damage or wear and tear.

7. What is your experience with different types of laminating materials?

I have experience with a variety of laminating materials, including:

- Polyester

- Polypropylene

- Vinyl

- Metalized

- Holographic

I am familiar with the different properties of these materials and how to choose the right material for the specific application.

8. How do you stay up-to-date on the latest advancements in laminating technology?

I stay up-to-date on the latest advancements in laminating technology by:

- Reading industry publications and attending trade shows.

- Consulting with equipment manufacturers and suppliers.

- Participating in online forums and discussion groups.

9. What is your availability for work?

I am available for work immediately. I am flexible with my work schedule and can work full-time or part-time.

10. What is your salary expectation?

My salary expectation is in line with the industry average for similar positions. I am open to negotiating a salary that is fair and commensurate with my experience and qualifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Laminating Machine Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Laminating Machine Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Laminating Machine Feeder is responsible for ensuring a smooth and efficient laminating process. They are responsible for feeding materials into the machine, ensuring that the materials are properly aligned and fed into the machine at the correct speed. They also monitor the machine’s operation and troubleshoot any problems that may occur.

1. Feed materials into the laminating machine

This is the most important responsibility of the Laminating Machine Feeder and requires close attention to detail. The feeder must ensure that the materials are fed into the machine in the correct order, at the correct speed, and at the correct angle. Failure to feed the materials into the machine correctly can result in damage to the materials or the machine itself.

2. Monitor the machine’s operation

The Laminating Machine Feeder must also monitor the machine’s operation to ensure that it is functioning properly. They must watch for any signs of trouble, such as jams, wrinkles, or tears in the materials. If they spot any problems, they must stop the machine and correct the problem before it causes damage.

3. Troubleshoot problems

The Laminating Machine Feeder must be able to troubleshoot any problems that may occur with the machine. They must be able to identify the source of the problem and take steps to correct it. Common problems include jams, wrinkles, tears, and bubbles. The feeder must be able to quickly and efficiently solve these problems to keep the machine running smoothly.

4. Ensure that the materials are properly aligned

The Laminating Machine Feeder must also ensure that the materials are properly aligned before they are fed into the machine. This is important to ensure that the materials are laminated correctly and that there are no wrinkles or bubbles in the finished product.

Interview Tips

To ace the interview for Laminating Machine Feeder, it is important to be prepared. Here are some tips that can help you prepare for the interview:

1. Research the company and the position

Before going to the interview, make sure to do your research about the company and the position. This will show the interviewer that you are interested in the position and that you have taken the time to learn about the company. You can research the company’s website, LinkedIn page, and Glassdoor to learn more about the company’s culture, values, and products.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is a good idea to practice your answers to these questions so that you can deliver them confidently and clearly in the interview.

3. Be prepared to discuss your experience

The interviewer will likely ask you about your experience working as a Laminating Machine Feeder. Be prepared to discuss your experience in detail, including the tasks you performed, the equipment you used, and the challenges you faced.

4. Be prepared to talk about your skills

The interviewer will also ask you about your skills as a Laminating Machine Feeder. Be prepared to discuss your skills in detail, including your ability to feed materials into the machine, monitor the machine’s operation, troubleshoot problems, and ensure that the materials are properly aligned.

5. Be enthusiastic and confident

Enthusiasm and confidence can go a long way in an interview. Be positive and excited about the position, and show the interviewer that you are confident in your abilities. This will make a good impression and increase your chances of getting the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Laminating Machine Feeder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.