Are you gearing up for an interview for a Head Doffer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Head Doffer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

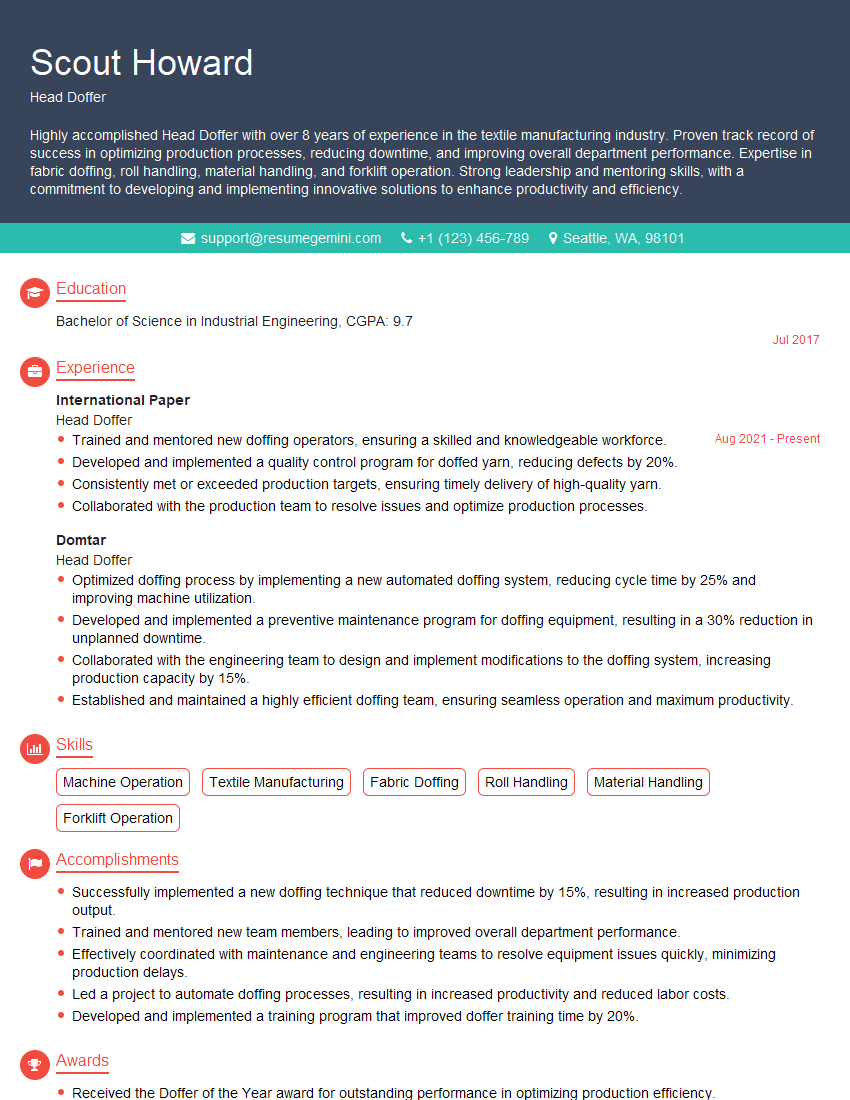

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Head Doffer

1. What are the key responsibilities of a Head Doffer in a textile manufacturing plant?

- Supervising and coordinating the doffing process, ensuring smooth and efficient removal of full bobbins and replacement with empty ones.

- Inspecting yarn quality, identifying any defects and taking corrective actions to minimize wastage.

- Monitoring machine performance, identifying potential issues, and coordinating with maintenance personnel for timely repairs.

- Training and mentoring doffers, ensuring they adhere to safety protocols and maintain high-quality standards.

- Collaborating with other departments, such as spinning and winding, to optimize production processes and minimize downtime.

2. Describe the different types of doffing systems used in textile manufacturing.

Manual Doffing

- Involves manually removing full bobbins and replacing them with empty ones.

- Requires physical strength and attention to detail.

- Suitable for small-scale or specialized operations.

Semi-Automatic Doffing

- Employs mechanical devices to assist with the doffing process.

- Reduces physical strain on operators.

- Increases efficiency and productivity.

Fully-Automatic Doffing

- Uses automated systems to remove full bobbins and replace them with empty ones.

- Eliminates manual labor, maximizing efficiency and minimizing downtime.

- Requires specialized equipment and maintenance.

3. What are the common yarn defects that can occur during the doffing process?

- End Breaks: Yarn breakage during doffing due to snagging or uneven tension.

- Double Ends: Two or more yarn ends being doffed onto a single bobbin.

- Yarn Contamination: Foreign particles or debris getting into the yarn during doffing.

- Uneven Winding: Yarn not being evenly distributed on the bobbin, leading to quality issues.

- Bobbin Damage: Scratches or dents on bobbins that can compromise yarn quality.

4. How do you ensure the quality of yarn during the doffing process?

- Visual Inspection: Regularly inspecting yarn for breaks, contamination, and uneven winding.

- Tension Monitoring: Using tension sensors to ensure yarn is doffed with the correct tension.

- Bobbin Cleaning: Cleaning bobbins before and after doffing to prevent contamination.

- Proper Storage: Storing yarn in a clean and dry environment to prevent damage or degradation.

- Regular Maintenance: Ensuring doffing machines are well-maintained to minimize defects.

5. Describe the safety protocols that must be followed during the doffing process.

- Wear appropriate PPE: Including safety glasses, gloves, and hearing protection.

- Clear the doffing area: Remove any obstacles or potential tripping hazards.

- Use proper lifting techniques: When handling heavy bobbins.

- Be aware of moving machinery: And keep a safe distance.

- Report any safety concerns: To supervisors or maintenance personnel immediately.

6. How do you motivate and train your team of doffers to achieve high performance?

- Set clear expectations: Communicate performance goals and standards to the team.

- Provide regular training: On doffing techniques, safety protocols, and quality standards.

- Offer incentives: For meeting or exceeding targets.

- Recognize and reward achievements: To boost morale and encourage continuous improvement.

- Foster a positive work environment: Where employees feel valued and respected.

7. What are the key performance indicators (KPIs) you use to measure the effectiveness of your doffing operation?

- Doffing Efficiency: Number of bobbins doffed per hour.

- Yarn Quality: Percentage of yarn free from defects.

- Downtime: Total time lost due to machine breakdowns or other issues.

- Safety Incident Rate: Number of accidents or near-misses related to doffing.

- Cost per Bobbin: Total cost of doffing divided by the number of bobbins doffed.

8. How do you stay up-to-date with the latest advancements in doffing technology and best practices?

- Attend industry conferences and workshops: To learn about new technologies and practices.

- Read technical publications and research papers: To stay informed about industry trends.

- Consult with equipment manufacturers: About product updates and technical advancements.

- Network with other professionals: In the field to exchange knowledge and ideas.

- Seek professional certifications: To demonstrate competence and knowledge in the field.

9. How do you handle a situation where there is a sudden increase in production demand and you have limited resources?

- Analyze production schedules: And identify areas where doffing capacity can be optimized.

- Cross-train staff: To increase flexibility and support multiple doffing lines.

- Prioritize critical doffing areas: To ensure essential processes are not disrupted.

- Communicate with management: To provide updates on the situation and request additional resources if necessary.

- Monitor progress closely: And make adjustments to the plan as needed.

10. Describe a challenging situation you faced in your previous role as a Head Doffer and how you overcame it.

- Situation: Unexpected machine breakdown led to a significant backlog of undoffed bobbins.

- Actions: Prioritized critical doffing areas, cross-trained staff, and coordinated with maintenance to expedite repairs.

- Outcome: Minimized downtime, maintained yarn quality, and achieved production targets despite the challenge.

- Learnings: Importance of contingency planning, effective communication, and teamwork in resolving production issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Head Doffer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Head Doffer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Head Doffer is the key person responsible for managing and coordinating all aspects of the doffing process in a textile mill. The Head Doffer’s roles and responsibilities include:

1. Managing and coordinating the doffing process

The Head Doffer is responsible for planning, organizing, and coordinating the doffing process. This involves ensuring that the doffers are trained and equipped to do their jobs effectively, that the doffing equipment is in good working order, and that the doffing process is running smoothly and efficiently.

- Plan and schedule doffing operations

- Supervise and train doffers

- Ensure that doffing equipment is in good working order

2. Monitoring and evaluating the doffing process

The Head Doffer is also responsible for monitoring and evaluating the doffing process to ensure that it is meeting the required standards. This involves tracking key performance indicators, such as doffing time and quality, and identifying areas for improvement.

- Track key performance indicators

- Identify areas for improvement

- Make recommendations for process improvements

3. Communicating with other departments

The Head Doffer works closely with other departments within the mill, such as the spinning department and the maintenance department, to ensure that the doffing process is running smoothly and efficiently. This involves communicating with other departments to identify and resolve any issues that may arise.

- Communicate with other departments

- Resolve issues that may arise

- Coordinate with maintenance department

4. Maintaining a safe and healthy work environment

The Head Doffer is responsible for maintaining a safe and healthy work environment for the doffers. This involves ensuring that the doffers are trained on safety procedures, that the doffing equipment is safe to use, and that the work area is clean and free of hazards.

- Ensure that doffers are trained on safety procedures

- Ensure that doffing equipment is safe to use

- Maintain a clean and hazard-free work area

Interview Tips

Preparing for an interview is a crucial step in securing your dream job. Here are a few tips to help you ace your interview for the Head Doffer position:

1. Research the company and the position

Before you go for the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also give you a better idea of what the job entails.

- Visit the company’s website

- Read about the company’s products or services

- Learn about the company’s culture and values

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked during an interview for a Head Doffer position. It is important to practice answering these questions in advance so that you can deliver polished and confident responses during your interview.

- Tell me about yourself

- Why are you interested in this position

- What are your strengths and weaknesses

3. Be prepared to talk about your experience

During your interview, you will be asked about your experience and qualifications. Be prepared to talk about your experience in doffing, as well as any other relevant experience that you have.

- Highlight your experience in doffing

- Talk about your experience in managing and coordinating teams

- Discuss your experience in safety and quality control

4. Be enthusiastic and professional

First impressions are important, so it is crucial to make a good impression during your interview. Be enthusiastic about the position and about the company, and be professional and respectful in your interactions with the interviewer.

- Dress professionally

- Arrive on time for your interview

- Be polite and respectful to the interviewer

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Head Doffer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!