Are you gearing up for an interview for a Heat Curer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Heat Curer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

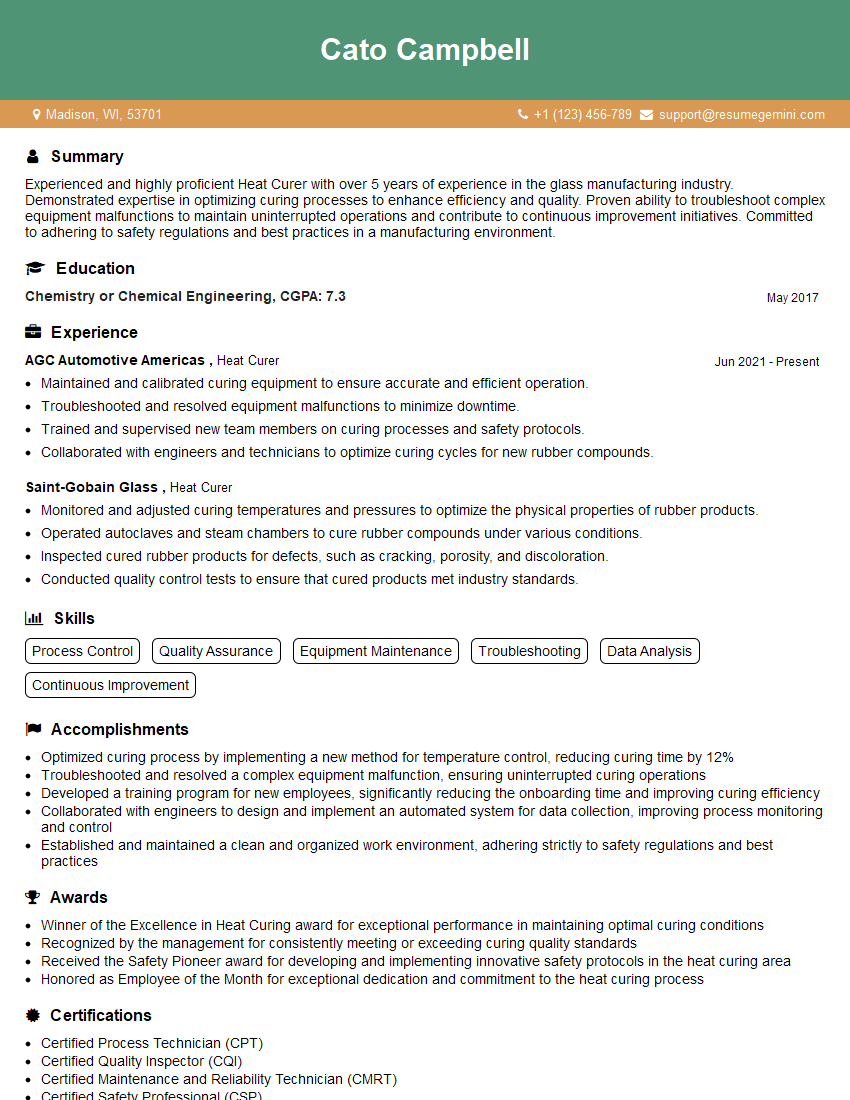

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heat Curer

1. What are the different types of heat curing processes?

There are three main types of heat curing processes:

- Convection curing: This process uses hot air to cure the material. It is the most common type of heat curing process and is used for a wide variety of materials.

- Radiation curing: This process uses ultraviolet (UV) or infrared (IR) radiation to cure the material. It is a faster process than convection curing and is used for materials that are sensitive to heat.

- Microwave curing: This process uses microwaves to cure the material. It is the fastest process and is used for materials that are not sensitive to heat.

2. What are the factors that affect the heat curing process?

Material properties

- The type of material being cured

- The thickness of the material

- The density of the material

Process parameters

- The temperature of the cure

- The duration of the cure

- The rate of heating and cooling

Environmental factors

- The temperature of the environment

- The humidity of the environment

- The presence of contaminants

3. What are the common defects that can occur during the heat curing process?

- Blisters

- Cracks

- Delamination

- Discoloration

- Warpage

4. How can these defects be prevented?

- Use the correct type of heat curing process for the material.

- Control the process parameters (temperature, duration, rate of heating and cooling).

- Ensure that the environment is clean and free of contaminants.

- Use proper handling and storage techniques for the cured material.

- Inspect the cured material for defects and reject any defective material.

5. What are the safety precautions that must be taken when working with heat curing processes?

- Wear appropriate personal protective equipment (PPE), such as gloves, eye protection, and a respirator.

- Handle hot materials with care and use proper lifting techniques.

- Be aware of the potential for fire and explosion and take appropriate precautions.

- Ventilate the work area to remove fumes and gases.

- Follow all safety procedures and guidelines.

6. What is the role of a Heat Curer?

- Operate and maintain heat curing equipment

- Monitor the curing process

- Identify and correct defects

- Ensure that the cured material meets the required specifications

- Follow safety procedures

7. What are the qualifications required to be a Heat Curer?

- High school diploma or equivalent

- Experience in operating and maintaining heat curing equipment

- Knowledge of heat curing processes

- Ability to identify and correct defects

- Ability to follow safety procedures

8. What is the salary range for a Heat Curer?

The salary range for a Heat Curer varies depending on experience, location, and employer. According to Salary.com, the average salary for a Heat Curer in the United States is between $35,000 and $50,000 per year.

9. What are the career opportunities for a Heat Curer?

- Heat Curer Supervisor

- Quality Control Inspector

- Product Engineer

- Manufacturing Manager

- Plant Manager

10. What is the work environment like for a Heat Curer?

- Heat Curers typically work in a factory or production environment.

- The work can be physically demanding and may require lifting heavy objects.

- The work environment can be hot and humid.

- Heat Curers may be exposed to chemicals and fumes.

- Heat Curers must follow safety procedures to avoid accidents.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heat Curer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heat Curer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Heat Curer is a highly skilled professional responsible for overseeing the curing process of rubber or plastic components. Their primary task is to ensure that these components meet the desired specifications and quality standards through the application of heat and pressure.

1. Curing Process Management

Heat Curers are responsible for planning and executing the curing process, which involves:

- Determining the appropriate curing temperature, time, and pressure settings

- Monitoring the curing process to ensure parameters are met

- Adjusting process variables as needed to optimize curing results

2. Equipment Operation and Maintenance

Heat Curers operate and maintain various equipment used in the curing process, including:

- Heat curing ovens or chambers

- Autoclaves

- Pressure vessels

3. Quality Assurance and Testing

Heat Curers perform quality assurance checks on cured components to ensure they meet specifications:

- Conducting visual inspections

- Performing physical and mechanical testing

- Analyzing test results and identifying any non-conformities

4. Process Improvement and Troubleshooting

Heat Curers continuously seek to improve the curing process by:

- Identifying and resolving process bottlenecks

- Implementing process modifications to enhance efficiency

- Collaborating with engineers and technicians to develop and implement solutions

Interview Tips

To excel in a Heat Curer interview, it’s crucial to:

1. Research the Company and Role

Thoroughly research the company’s products, industry, and specific curing processes they employ. This shows genuine interest and preparation for the role.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating and maintaining curing equipment. Showcase your understanding of curing principles and quality control techniques.

3. Demonstrate Problem-Solving Abilities

Share examples of how you have identified and resolved problems during the curing process. This demonstrates your analytical and troubleshooting skills.

4. Discuss Process Improvement Initiatives

Discuss any initiatives you have undertaken to optimize curing processes or reduce cycle times. This highlights your proactive approach and commitment to continuous improvement.

5. Ask Thoughtful Questions

Prepare thoughtful questions about the company’s curing processes, quality standards, and opportunities for professional development. Asking insightful questions shows engagement and curiosity.

Next Step:

Now that you’re armed with the knowledge of Heat Curer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Heat Curer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini