Are you gearing up for a career in Fusing Furnace Loader? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Fusing Furnace Loader and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

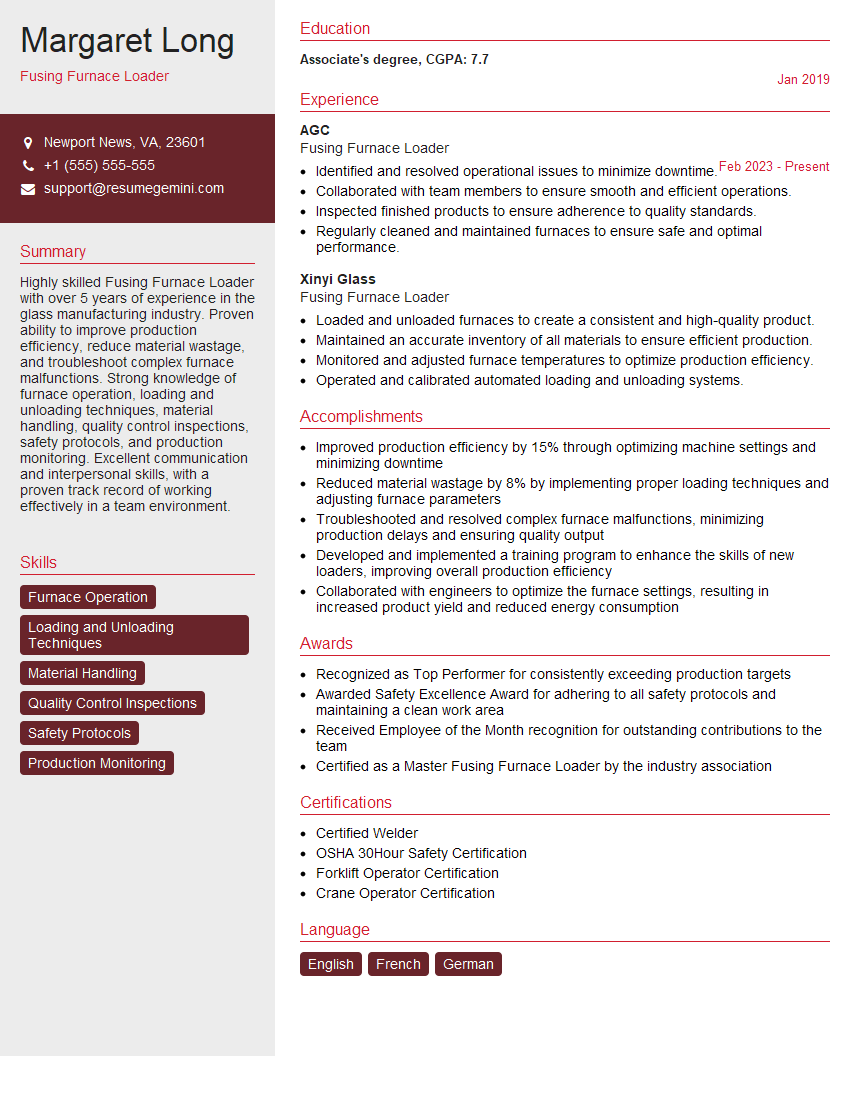

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fusing Furnace Loader

1. Explain the role of a Fusing Furnace Loader.

As a Fusing Furnace Loader, I will be responsible for loading glass sheets onto a conveyor belt that feeds into the fusing furnace. Once the glass has been fused, I will remove it from the furnace and place it in a cooling rack. My duties will also include maintaining the furnace and surrounding work area, and monitoring the production process to ensure that the glass is fused properly.

2. What are the safety precautions that need to be taken when working with a Fusing Furnace?

Proper Clothing and Gear

- Wear heat-resistant gloves, protective apron, and closed-toe shoes.

- Use safety glasses to shield eyes from flying glass particles.

Safe Furnace Operation

- Only operate the furnace when properly trained and authorized.

- Keep the furnace area clear of combustible materials.

- Never reach into the furnace while it is operating.

Emergency Preparedness

- Familiarize oneself with the location of fire extinguishers and emergency exits.

- Know how to shut off the furnace in case of an emergency.

3. What are the different types of glass that can be fused in a Fusing Furnace?

There are various types of glass that can be fused, including:

- Float glass: Clear, flat glass commonly used in windows and doors.

- Bullseye glass: Colored, translucent glass specifically designed for fusing.

- Dichroic glass: Glass with a thin metallic coating that reflects different colors depending on the viewing angle.

- Frit glass: Powdered glass used to create designs and patterns on the fused glass.

- Clear and opaque art glass: Specialty glass with unique textures, colors, and opacities for artistic purposes.

4. What are the key factors that affect the quality of fused glass?

The quality of fused glass is influenced by several factors:

- Glass selection: The type and compatibility of the glasses used.

- Temperature control: Maintaining the correct temperature throughout the fusing process.

- Annealing: A controlled cooling process that prevents the glass from cracking or breaking.

- Cleanliness: Keeping the furnace and tools clean to avoid contamination.

- Skill and experience: The operator’s expertise in handling the glass and operating the furnace.

5. Describe the process of loading and unloading a Fusing Furnace.

Loading

- Prepare the glass sheets by cleaning and arranging them on a refractory shelf.

- Carefully place the shelf into the furnace using a furnace loader.

- Set the temperature and timer according to the specific glass type and desired result.

Unloading

- Once the fusing cycle is complete, allow the furnace to cool gradually.

- Use heat-resistant gloves and tongs to remove the shelf from the furnace.

- Transfer the fused glass to a cooling rack and allow it to cool further before handling.

6. How do you troubleshoot common problems that may arise during the Fusing Furnace operation?

Common problems and troubleshooting steps include:

- Cracked or broken glass: Check for excessive temperature or uneven heating. Anneal the glass properly.

- Bubbles or inclusions: Clean the glass and furnace thoroughly. Use compatible glass types.

- Uneven fusion: Ensure proper temperature distribution and contact between glass layers.

- Discoloration: Identify the source of contamination, such as dirty tools or furnace elements.

- Furnace malfunction: Contact a qualified technician for repairs or maintenance.

7. What maintenance tasks are required for a Fusing Furnace?

Regular maintenance is crucial for optimal furnace performance and safety:

- Daily: Clean the furnace chamber, shelves, and elements.

- Weekly: Inspect the heating elements and wiring for damage.

- Monthly: Calibrate the temperature controller and check the safety systems.

- Quarterly: Conduct a thorough cleaning and inspection of all furnace components.

- Annually: Schedule a professional maintenance and inspection by a qualified technician.

8. How do you ensure the safety of yourself and others while working with a Fusing Furnace?

Safety is of utmost importance:

- Wear appropriate safety gear, including heat-resistant gloves, apron, and safety glasses.

- Follow proper operating procedures and never override safety mechanisms.

- Keep the work area clean and free of tripping hazards.

- Be aware of the location of emergency equipment and fire extinguishers.

- Never work alone and have someone nearby in case of an emergency.

9. What is your experience with different types of Fusing Furnaces?

I have worked with various types of Fusing Furnaces, including:

- Electric Kiln: Used for smaller-scale fusing projects with precise temperature control.

- Gas Kiln: Provides higher temperatures for larger glass pieces, offering versatility and efficiency.

- Shuttle Kiln: Ideal for continuous production, allowing for loading and unloading without interrupting the process.

10. How do you stay up-to-date with the latest Fusing Furnace technologies and techniques?

I stay current with industry advancements through:

- Attending workshops and conferences.

- Reading trade publications and online resources.

- Connecting with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fusing Furnace Loader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fusing Furnace Loader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fusing Furnace Loaders are responsible for a range of tasks related to the operation and maintenance of fusing furnaces, which are used to melt and blend materials in various industrial settings.

1. Loading and Unloading Furnace

Loaders are responsible for loading and unloading the furnace with materials, following established procedures to ensure safety and efficiency. They may use hand tools, such as shovels or scoops, to transfer materials from storage containers to the furnace, and vice-versa.

2. Monitoring Furnace Operation

Loaders are responsible for monitoring the furnace operation, including temperature and pressure readings, to ensure that the furnace is functioning properly. They may also make adjustments to the furnace settings as needed to maintain optimal operating conditions.

3. Maintaining Furnace Equipment

Loaders are responsible for maintaining the furnace equipment, including cleaning, lubrication, and minor repairs. They may also perform regular inspections of the furnace to identify any potential issues or required maintenance.

4. Safety Compliance

Loaders are responsible for adhering to safety regulations and guidelines related to the operation of the furnace. This includes wearing appropriate protective gear, following established safety procedures, and reporting any unsafe conditions to supervisors.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you prepare for an interview for a Fusing Furnace Loader position:

1. Research the Company and Position

Take the time to research the company you are applying to and the specific position you are interested in. This will help you understand their industry, values, and the specific requirements of the job. You can find this information on the company’s website, social media pages, and industry publications.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the interview. Consider using the STAR method to answer questions, which involves providing a Situation, Task, Action, and Result for each answer.

3. Highlight Relevant Skills and Experience

In your interview, be sure to emphasize the skills and experience that are most relevant to the job requirements. Use specific examples to demonstrate your abilities and explain how they have benefited previous employers. Quantify your accomplishments whenever possible using metrics or data to showcase your results.

4. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that are specific to the job or the company, demonstrating your enthusiasm and curiosity about the opportunity.

Next Step:

Now that you’re armed with the knowledge of Fusing Furnace Loader interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Fusing Furnace Loader positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini