Are you gearing up for a career in Fringing Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Fringing Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

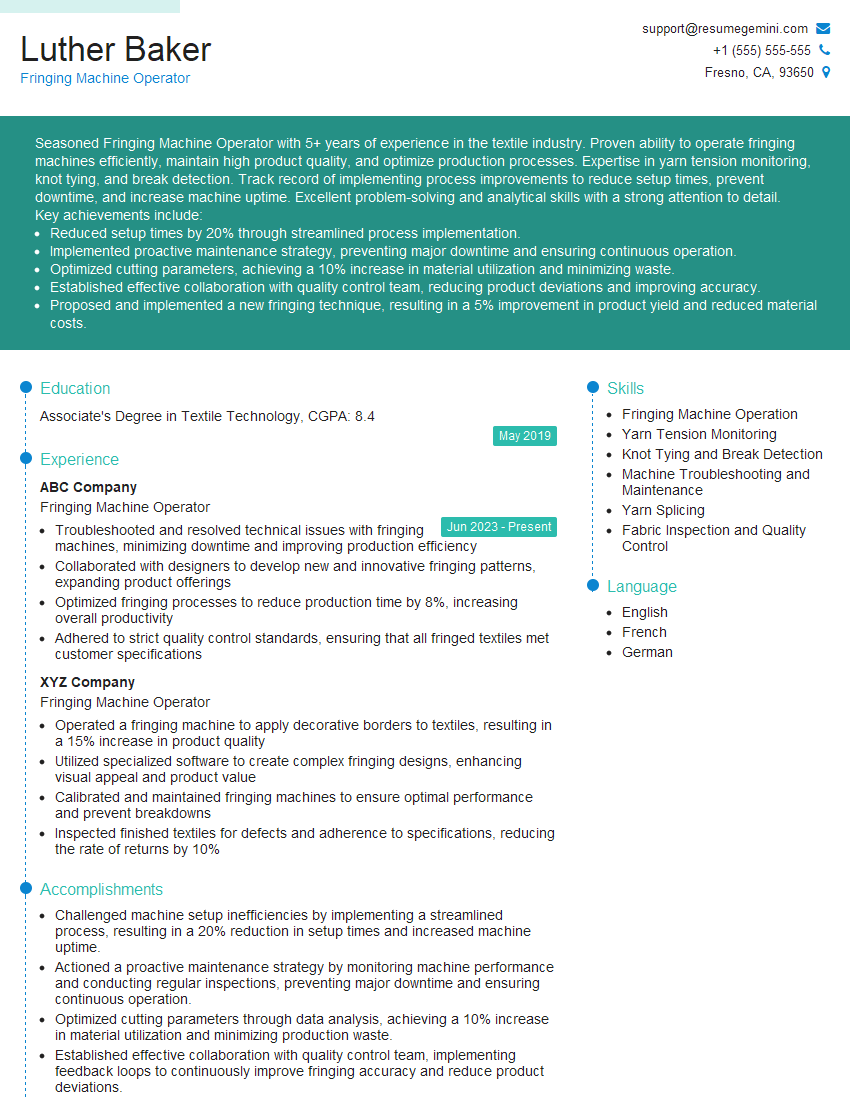

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fringing Machine Operator

1. Explain the key features and functionalities of a Fringing Machine?

A Fringing Machine is a critical component in the production of printed circuit boards (PCBs) and other electronic devices. Its primary function is to remove excess copper from the PCB after the etching process, creating a clean and defined edge around the copper traces.

- Controllable Spindle Speed: Allows for precise adjustment of the spindle speed to suit different PCB materials and thicknesses.

- Programmable Feed Rate: Enables customization of the speed at which the machine moves along the PCB, ensuring accurate and consistent fringing.

- Automatic Tool Changer: Facilitates quick and efficient tool changes for different fringing operations, minimizing downtime.

- Dust Collection System: Helps maintain a clean and safe work environment by removing copper dust generated during the fringing process.

- User-friendly Interface: Simplifies machine operation and reduces the need for extensive training.

2. Describe the different types of Fringing Cutters and their applications?

High-Speed Steel (HSS) Cutters

- Suitable for general-purpose fringing operations.

- Economical and widely available.

Carbide Cutters

- More durable and longer-lasting than HSS cutters.

- Ideal for high-volume production and demanding applications.

Diamond Cutters

- Provide the highest level of precision and edge quality.

- Used for critical applications and fine-pitch PCBs.

3. How do you determine the appropriate fringing parameters for different PCB materials and thicknesses?

The selection of fringing parameters depends on several factors, including:

- PCB Material: Different materials, such as FR4, CEM-1, and polyimide, have varying properties that influence the optimal fringing parameters.

- PCB Thickness: Thicker PCBs require higher spindle speeds and slower feed rates to avoid excessive burring or undercutting.

- Copper Thickness: Thicker copper traces necessitate higher spindle speeds to ensure clean cutting.

- Desired Edge Quality: The desired edge quality and smoothness dictate the selection of appropriate cutters and fringing parameters.

4. Explain the importance of maintaining the Fringing Machine for optimal performance?

Regular maintenance of the Fringing Machine is crucial to ensure its optimal performance and longevity. Key maintenance tasks include:

- Cleaning and Inspection: Regularly cleaning the machine and inspecting its components for wear or damage can prevent unexpected breakdowns.

- Lubrication: Proper lubrication of moving parts, such as the spindle bearings and feed system, reduces friction and prolongs their life.

- Tool Maintenance: Sharpening or replacing worn-out fringing cutters ensures precise and efficient cutting operations.

- Calibration: Periodic calibration of the machine’s sensors and control system ensures accurate and repeatable fringing results.

5. Describe the potential hazards associated with Fringing Machine operation and the safety precautions to minimize them?

Hazards:

- Rotating Spindle: Can cause injuries if operators come into contact with it.

- Sharp Cutters: Can cause cuts or lacerations if handled improperly.

- Copper Dust: Inhalation of copper dust can lead to respiratory problems.

- Electrical Hazards: Improper handling of electrical components can result in electrical shocks.

Safety Precautions:

- Wear appropriate PPE: Safety glasses, gloves, and earplugs should be worn during operation.

- Follow lockout/tagout procedures: Isolate the machine from power before performing maintenance or repairs.

- Handle cutters with care: Use proper tooling to remove and replace cutters, avoiding direct contact with sharp edges.

- Keep the work area clean: Vacuum or sweep the work area regularly to minimize copper dust accumulation.

- Train operators thoroughly: Provide comprehensive training on safe operation and emergency procedures.

6. How do you troubleshoot common problems encountered during Fringing Machine operation?

Problem: Excessive burring or undercutting

- Check spindle speed and feed rate settings.

- Inspect cutter for wear or damage.

- Adjust the depth of cut.

Problem: Poor edge quality

- Use a higher-quality cutter.

- Optimize spindle speed and feed rate parameters.

- Check for proper alignment of the machine and workpiece.

Problem: Machine vibration

- Inspect the spindle for any imbalances.

- Check the machine mounting and ensure it is level.

- Tighten any loose screws or bolts.

7. What is the role of Fringing Machine operators in a PCB manufacturing environment?

Fringing Machine operators play a vital role in the PCB manufacturing process. Their responsibilities include:

- Machine Setup and Operation: Setting up and operating the Fringing Machine according to specified parameters.

- Quality Control: Inspecting finished PCBs to ensure they meet the required edge quality and dimensional tolerances.

- Maintenance and Troubleshooting: Performing routine maintenance tasks and troubleshooting any operational issues.

- Process Improvement: Identifying areas for process optimization and suggesting improvements to enhance efficiency and quality.

8. How do you stay updated with the latest advancements in Fringing Machine technology?

- Attend industry conferences and workshops: Participate in events where vendors showcase new technologies and best practices.

- Read trade publications and online forums: Keep up with industry news and technical articles.

- Engage with equipment manufacturers: Contact suppliers to learn about the latest developments and potential upgrades for existing machines.

- Attend training courses: Take advantage of training opportunities offered by manufacturers or training providers to enhance skills and knowledge.

9. Can you describe a time when you had to solve a complex problem related to Fringing Machine operation?

Once, during a production run, we encountered excessive burring on the edges of the PCBs. After checking the spindle speed and feed rate, we noticed that the cutter was beginning to dull. We proactively replaced the cutter and adjusted the depth of cut, which resolved the issue and maintained the desired edge quality throughout the rest of the production run.

10. What techniques do you use to ensure the accuracy and precision of the Fringing Machine?

- Regular Calibration: Periodically calibrate the machine’s sensors and control system to ensure precise measurements and repeatable results.

- Proper Tooling: Use high-quality cutters and tooling designed specifically for fringing operations.

- Optimized Feed Rates and Spindle Speeds: Determine the optimal parameters for different PCB materials and thicknesses to achieve the desired edge quality.

- Visual Inspection: Regularly inspect the machine and workpiece to identify any potential issues that could affect accuracy.

- Statistical Process Control: Implement statistical process control techniques to monitor and adjust the machine’s performance over time.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fringing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fringing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Fringing Machine Operator is responsible for operating and maintaining a fringing machine. The machine fringes yarn, which is a process that involves twisting the yarn to create a fluffy, decorative effect.

1. Production Responsibilities

The key production responsibilities of a Fringing Machine Operator include:

- Operate the fringing machine according to established procedures to twist and fringe yarn.

- Inspect the yarn before and after fringing to ensure that it meets quality standards.

- Maintain and adjust the fringing machine to ensure optimal performance.

2. Quality Assurance Responsibilities

The Fringing Machine Operator is also responsible for quality assurance, which includes:

- Monitoring the fringing process to ensure that the yarn is twisted and fringed to the correct specifications.

- Identifying and correcting any defects in the fringing process.

- Maintaining a log of all quality checks and corrective actions taken.

3. Safety Responsibilities

The Fringing Machine Operator is also responsible for safety, which includes:

- Following all safety regulations and procedures when operating the fringing machine.

- Keeping the work area clean and free of hazards.

- Reporting any safety concerns to the supervisor immediately.

4. Other Responsibilities

In addition to the above, the Fringing Machine Operator may also be responsible for:

- Training new employees on the fringing machine.

- Assisting with the development and implementation of new fringing techniques.

- Troubleshooting and repairing minor problems with the fringing machine.

Interview Preparation Tips

To help you ace your interview for a Fringing Machine Operator position, here are some tips:

1. Research the company and the position

Before your interview, take some time to learn about the company and the specific position you’re applying for. This will help you understand the company’s culture and values, and it will also help you answer questions about your qualifications and experience more effectively.

2. Practice answering common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice answering these questions in advance so that you can deliver your responses confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Fringing Machine Operator. Be prepared to provide specific examples of your work and how you’ve contributed to the success of your previous employers.

4. Ask questions about the position and the company

At the end of the interview, you’ll have an opportunity to ask questions of the interviewer. This is your chance to learn more about the position and the company, and it’s also a way to show the interviewer that you’re interested and engaged.

5. Follow up after the interview

After the interview, send a thank-you note to the interviewer. This is a simple way to show your appreciation for their time and it can also help you stay top-of-mind for the position.

Following these tips will help you prepare for and ace your interview for a Fringing Machine Operator position. Good luck!Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Fringing Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Fringing Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.