Feeling lost in a sea of interview questions? Landed that dream interview for Beater and Pulper Feeder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Beater and Pulper Feeder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

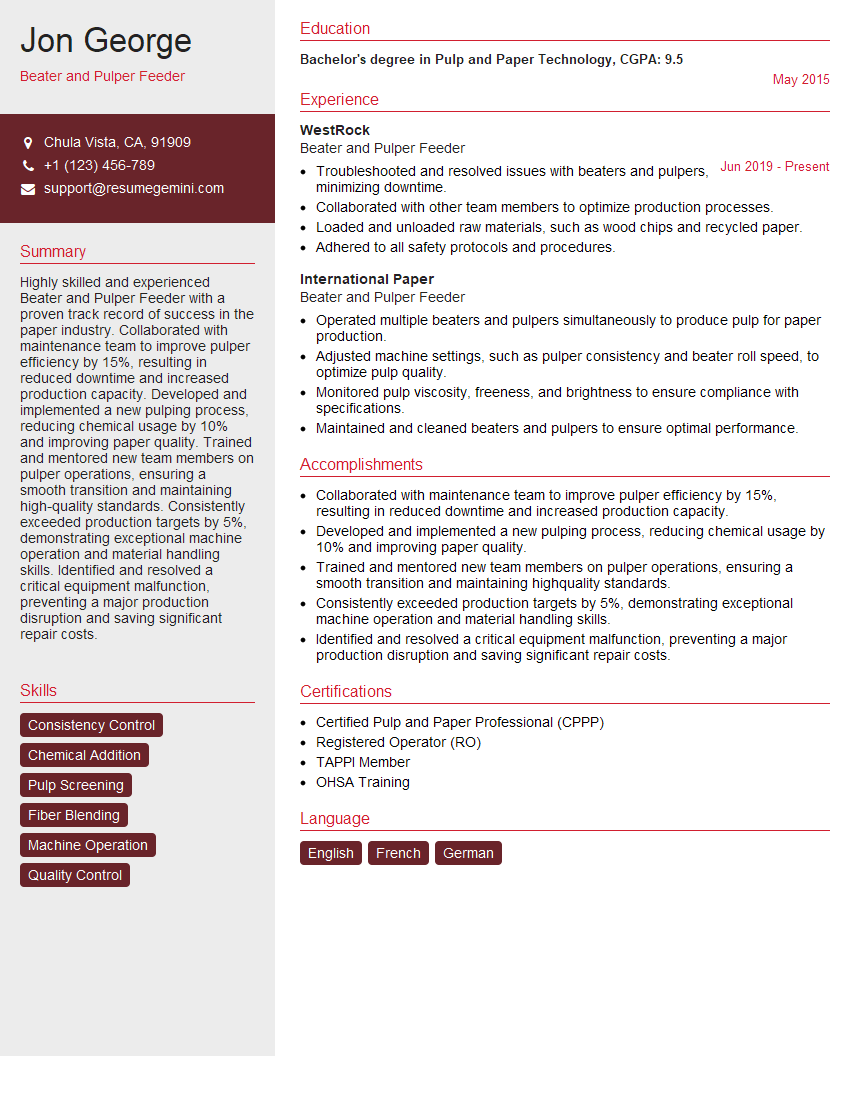

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beater and Pulper Feeder

1. What are the different types of beaters used in a paper mill?

The different types of beaters used in a paper mill are:

- Hollander beater: This beater is used to beat rags and other fibrous materials.

- Kollergang beater: This beater is used to beat pulp into a fine, uniform consistency.

- Jordan beater: This beater is used to beat pulp to develop strength and improve formation.

2. What are the functions of a pulper?

The functions of a pulper are to:

- Break down wastepaper and other fibrous materials into a slurry.

- Remove contaminants from the slurry, such as dirt, sand, and metal.

- Prepare the slurry for further processing, such as beating and refining.

3. What are the different types of pulpers?

The different types of pulpers are:

- Batch pulper: This pulper operates in a batch process, where a fixed amount of material is added to the pulper and processed for a set period of time.

- Continuous pulper: This pulper operates in a continuous process, where material is continuously added to the pulper and processed.

- Hydrapulper: This pulper uses high-pressure water jets to break down material.

- Disc pulper: This pulper uses rotating discs to break down material.

4. What are the factors that affect the efficiency of a pulper?

The factors that affect the efficiency of a pulper are:

- The type of material being processed.

- The size of the material being processed.

- The consistency of the slurry.

- The temperature of the slurry.

- The speed of the pulper.

5. What are the safety precautions that should be taken when operating a pulper?

The safety precautions that should be taken when operating a pulper are:

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and earplugs.

- Keep the area around the pulper clean and free of debris.

- Never put your hands or feet into the pulper while it is operating.

- Be aware of the potential for explosions when adding chemicals to the pulper.

- Follow all manufacturer’s instructions for operating the pulper.

6. What are the maintenance procedures that should be performed on a pulper?

The maintenance procedures that should be performed on a pulper are:

- Regularly inspect the pulper for wear and tear.

- Lubricate the pulper’s bearings and other moving parts.

- Clean the pulper’s screens and other components.

- Replace the pulper’s blades and other worn parts as needed.

- Follow all manufacturer’s instructions for maintaining the pulper.

7. What are the different types of beater rolls?

The different types of beater rolls are:

- Steel beater rolls: These rolls are made of steel and are used for general beating.

- Stone beater rolls: These rolls are made of stone and are used for fine beating.

- Synthetic beater rolls: These rolls are made of synthetic materials and are used for a variety of beating applications.

8. What are the factors that affect the quality of the pulp produced by a beater?

The factors that affect the quality of the pulp produced by a beater are:

- The type of beater roll used.

- The speed of the beater roll.

- The consistency of the pulp.

- The temperature of the pulp.

- The addition of chemicals to the pulp.

9. What are the safety precautions that should be taken when operating a beater?

The safety precautions that should be taken when operating a beater are:

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and earplugs.

- Keep the area around the beater clean and free of debris.

- Never put your hands or feet into the beater while it is operating.

- Be aware of the potential for explosions when adding chemicals to the beater.

- Follow all manufacturer’s instructions for operating the beater.

10. What are the maintenance procedures that should be performed on a beater?

The maintenance procedures that should be performed on a beater are:

- Regularly inspect the beater for wear and tear.

- Lubricate the beater’s bearings and other moving parts.

- Clean the beater’s screens and other components.

- Replace the beater’s blades and other worn parts as needed.

- Follow all manufacturer’s instructions for maintaining the beater.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beater and Pulper Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beater and Pulper Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Beater and Pulper Feeder is primarily responsible for feeding raw materials into a beater and a pulper.

1. Beater

The Beater is a machine that blends and pulps rags, wastepaper, and other materials to produce paper pulp.

- Load the beater with raw materials and chemicals

- Operate the beater to blend and pulp the materials

- Monitor the beater’s operation and make adjustments as needed

- Unload the beater once the pulping process is complete

2. Pulper

The Pulper is a machine that breaks down wastepaper and other materials into a slurry.

- Load the pulper with wastepaper and other materials

- Operate the pulper to break down the materials

- Monitor the pulper’s operation and make adjustments as needed

- Unload the pulper once the pulping process is complete

3. General Duties

In addition to their specific duties, Beater and Pulper Feeders may also be responsible for:

- Cleaning and maintaining the beater and pulper

- Assisting with the loading and unloading of materials

- Following safety procedures

- Working with other team members to ensure a smooth and efficient operation

Interview Tips

Preparing for an interview for a Beater and Pulper Feeder position can help you present yourself as a qualified candidate and increase your chances of landing the job. Here are a few tips to help you prepare:

1. Research the company and the position

Take some time to learn about the company you’re applying to and the specific position you’re interested in. This will help you better understand the company’s culture, values, and goals, and it will also help you tailor your answers to the interviewer’s questions.

2. Practice answering common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Practice answering these questions in a clear and concise manner, and be sure to highlight your skills and experience that are relevant to the position.

3. Be prepared to talk about your experience

The interviewer will likely want to know about your previous experience, so be prepared to talk about your job duties, responsibilities, and accomplishments. If you have any specific experience that is relevant to the position, be sure to highlight it.

4. Dress professionally

First impressions matter, so be sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

5. Be on time

Punctuality is important, so be sure to arrive for your interview on time. If you’re running late, be sure to call or email the interviewer to let them know.

6. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Beater and Pulper Feeder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!