Feeling lost in a sea of interview questions? Landed that dream interview for Base Remover but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Base Remover interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

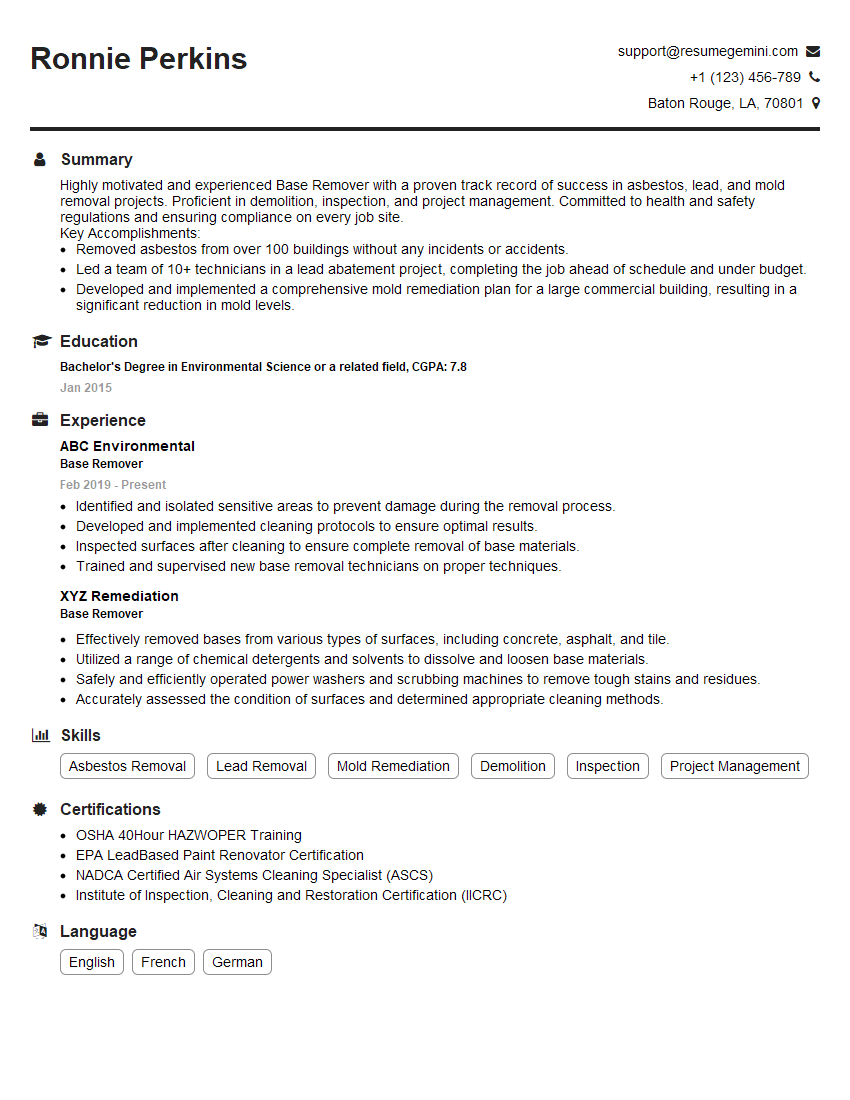

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Base Remover

1. Describe the process of removing base from a substrate?

The process of removing base from a substrate involves several steps:

- Preparation: Before removing the base, the substrate must be prepared by cleaning it to remove any contaminants or debris.

- Selection of a remover: The type of remover used depends on the type of base being removed. Common removers include chemical strippers, mechanical abrasives, and heat guns.

- Application of the remover: The remover is applied to the substrate using a brush, roller, or spray gun. The application method depends on the remover being used.

- Dwell time: The remover is allowed to dwell on the substrate for a specific amount of time to allow it to penetrate and dissolve the base.

- Removal: After the dwell time, the dissolved base is removed using a scraper, brush, or power washer. The removal method depends on the substrate and the type of remover used.

- Cleanup: The substrate is cleaned to remove any remaining remover or dissolved base. The cleanup method depends on the remover being used.

2. What are the different types of base removers?

Chemical strippers

- Solvent-based: These removers contain solvents that dissolve the base. They are highly effective but can be harmful to the environment and require proper ventilation.

- Water-based: These removers contain water-based solutions that break down the base. They are less harmful to the environment but may not be as effective as solvent-based removers.

Mechanical abrasives

- Sandpaper: Sandpaper can be used to manually remove the base by sanding it away. This method is labor-intensive and can damage the substrate if not done properly.

- Power sanders: Power sanders can be used to remove the base more quickly and efficiently than sandpaper. However, they can also damage the substrate if not used properly.

Heat guns

- Heat guns can be used to soften the base so that it can be scraped off. This method can be effective for removing thin layers of base but can damage the substrate if not done properly.

3. What factors should be considered when selecting a base remover?

- Type of base: The type of base being removed will determine the type of remover that is most effective.

- Substrate: The substrate being removed from will determine the type of remover that can be used without damaging it.

- Desired removal method: The desired removal method will determine the type of remover that is most suitable.

- Safety and environmental concerns: The safety and environmental impact of the remover should be considered before selecting it.

4. What safety precautions should be taken when using base removers?

- Wear appropriate safety gear: Wear gloves, eye protection, and a respirator when using base removers.

- Ensure proper ventilation: Use base removers in a well-ventilated area to avoid inhaling harmful vapors.

- Avoid contact with skin and eyes: If the remover comes into contact with skin or eyes, rinse immediately with plenty of water.

- Dispose of the remover properly: Dispose of the remover according to local regulations.

5. What are some common mistakes to avoid when using base removers?

- Using the wrong remover: Using the wrong remover can damage the substrate or be ineffective.

- Not following the instructions: Not following the instructions for the remover can lead to improper removal or damage to the substrate.

- Not taking safety precautions: Not taking proper safety precautions can lead to injuries or health problems.

6. Describe the process of removing base from a concrete surface.

- Prepare the surface: Clean the concrete surface to remove any contaminants or debris.

- Select a remover: Choose a remover that is specifically designed for removing base from concrete.

- Apply the remover: Apply the remover to the concrete surface using a brush, roller, or spray gun.

- Dwell time: Allow the remover to dwell on the concrete surface for the specified amount of time.

- Remove the dissolved base: Use a scraper, brush, or power washer to remove the dissolved base from the concrete surface.

- Cleanup: Clean the concrete surface to remove any remaining remover or dissolved base.

7. What are some of the challenges associated with removing base from a concrete surface?

- Concrete is a porous material: Concrete is a porous material, which means that the remover can penetrate the surface and damage the concrete.

- Concrete can be difficult to clean: Concrete can be difficult to clean, which can make it difficult to remove all of the dissolved base.

- Concrete can be expensive to repair: If the concrete surface is damaged during the removal process, it can be expensive to repair.

8. What are some of the benefits of using a professional base remover?

- Expertise: Professional base removers have the expertise to remove base from a variety of surfaces without damaging them.

- Safety: Professional base removers take proper safety precautions to protect themselves and others from the hazards of base removers.

- Efficiency: Professional base removers have the experience and equipment to remove base quickly and efficiently.

9. What are some of the factors that affect the cost of base removal?

- Type of base: The type of base being removed will affect the cost of removal.

- Surface area: The surface area of the base being removed will affect the cost of removal.

- Location: The location of the base being removed will affect the cost of removal.

- Accessibility: The accessibility of the base being removed will affect the cost of removal.

10. What are some of the latest trends in base removal technology?

- Laser removal: Laser removal is a new technology that uses lasers to remove base from surfaces. This technology is still in its early stages of development, but it has the potential to be a more efficient and environmentally friendly way to remove base.

- Biodegradable removers: Biodegradable removers are a new type of remover that is made from plant-based materials. These removers are less harmful to the environment than traditional removers.

- Robotic removal: Robotic removal is a new technology that uses robots to remove base from surfaces. This technology is still in its early stages of development, but it has the potential to be a more efficient and safer way to remove base.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Base Remover.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Base Remover‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Base Removers are responsible for removing hazardous materials from surfaces, such as paint, lead, and asbestos. They must follow strict safety protocols to protect themselves and others from exposure to these materials.

1. Health and Safety

Base Removers must follow all safety regulations and wear appropriate personal protective equipment (PPE) when working with hazardous materials.

- Follow all safety regulations and wear appropriate PPE

- Identify and assess potential hazards

2. Communication and Teamwork

Base Removers must be able to communicate effectively with other workers, supervisors, and clients. They must also be able to work effectively as part of a team.

- Communicate effectively with other workers, supervisors, and clients

- Work effectively as part of a team

3. Problem-Solving and Decision-Making

Base Removers must be able to solve problems and make decisions quickly and effectively. They must also be able to think critically and creatively to find solutions to complex problems.

- Solve problems and make decisions quickly and effectively

- Think critically and creatively to find solutions to complex problems

4. Other Responsibilities

In addition to the above, Base Removers may also be responsible for the following:

- Transporting hazardous materials

- Disposing of hazardous materials

- Maintaining equipment and supplies

- Training new employees

Interview Tips

Interviewing for a Base Remover position can be competitive. However, by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before your interview, take some time to research both the company. This will show the interviewer that you are interested in the job and that you have taken the time to learn more about the company and understand the industry.

- Visit the company’s website

- Read articles about the company and the industry

- Talk to people who work at the company

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. By practicing your answers to these questions, you can increase your confidence and delivery.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with hazardous materials?

3. Be Prepared to Discuss Your Safety Experience

As a Base Remover, you will be responsible for following strict safety protocols. In your interview, be prepared to discuss your safety experience and how you would handle potential hazards on the job.

- Describe a time when you had to follow safety protocols.

- What are some of the potential hazards that you could encounter as a Base Remover?

- How would you handle a situation where you were exposed to hazardous materials?

4. Be Professional and Enthusiastic

First impressions matter. When you arrive for your interview, be sure to dress professionally and arrive on time. During the interview, be polite and respectful to the interviewer. And don’t forget to smile and make eye contact.

- Dress professionally

- Arrive on time

- Be polite and respectful

- Smile and make eye contact

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Base Remover, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Base Remover positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.