Feeling lost in a sea of interview questions? Landed that dream interview for Spike Driver but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Spike Driver interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

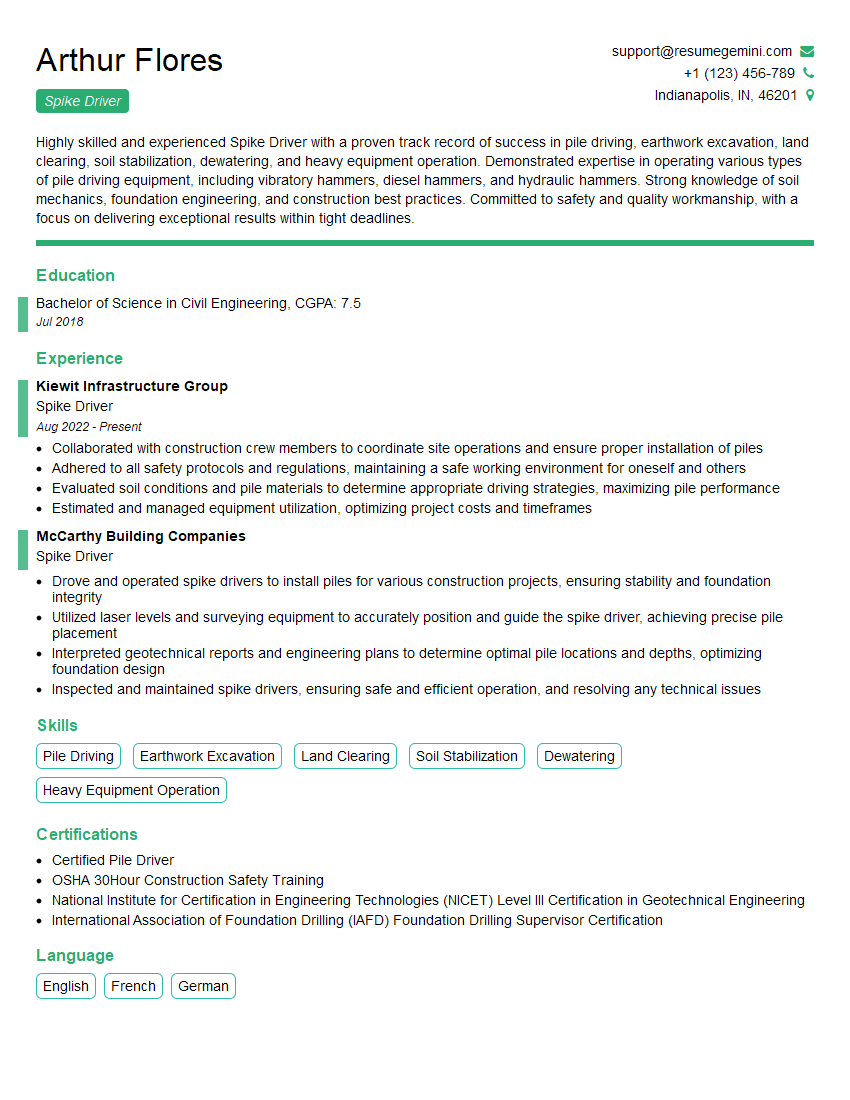

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spike Driver

1. Tell me about your previous experience with pile driving as a Spike Driver?

In my previous role as a Spike Driver, I was responsible for driving and extracting steel piles into the ground to create support structures for various construction projects. My duties included:

- Operating a pile driving rig to maneuver and position the piles accurately.

- Monitoring the driving process and adjusting parameters to ensure compliance with project specifications.

- Inspecting piles and accessories to ensure their integrity and safety.

- Working in close coordination with engineers and construction teams to ensure timely and efficient pile driving.

- Maintaining a clean and organized worksite, adhering to safety protocols, and following company policies.

2. What are the key safety considerations that you prioritize during pile driving operations?

Worksite Preparation

- Ensuring the worksite is clear of hazards and potential obstacles.

- Properly marking and barricading the area to prevent unauthorized access.

- Establishing clear communication channels with other crew members.

Equipment Inspection

- Thoroughly inspecting the pile driving rig and accessories before operation.

- Checking for any signs of damage, wear, or loose connections.

- Ensuring all safety features are functional.

Personal Protective Equipment

- Wearing appropriate personal protective equipment, including hard hat, safety glasses, gloves, and hearing protection.

- Maintaining proper footing and avoiding loose clothing.

- Using hand signals or other communication methods to minimize verbal distractions.

3. How do you determine the appropriate driving force and frequency for different pile types and soil conditions?

The appropriate driving force and frequency for pile driving depend on several factors, including:

- Pile Type: Different pile types have varying load-bearing capacities and require specific driving parameters.

- Soil Conditions: The density, composition, and moisture content of the soil influence the driving resistance and require adjustments in force and frequency.

- Project Specifications: The project specifications often specify the required driving criteria, such as pile embedment depth and allowable tolerances.

- Experience and Engineering Analysis: Experience and engineering analysis play a crucial role in determining the optimal driving parameters, especially for challenging soil conditions or complex pile types.

4. What are the common challenges faced during pile driving and how do you overcome them?

Some common challenges faced during pile driving include:

- Obstructions: Encountering boulders, buried utilities, or other obstructions can hinder pile driving. Careful site investigation and probing can help identify potential hazards.

- Soil Conditions: Variable soil conditions can affect driving performance. Adjustments to driving parameters, such as force and frequency, may be necessary to overcome resistance.

- Pile Damage: Pile damage can occur during driving due to excessive force or improper techniques. Regular pile inspections and monitoring can help prevent damage.

- Noise and Vibration: Pile driving can generate noise and vibrations, which require proper mitigation measures to minimize impact on surroundings.

5. Describe the different types of pile driving equipment and their applications.

- Impact Hammers: Used for driving piles into dense soils; operate by repeatedly striking the pile head with a heavy weight.

- Vibratory Hammers: Generate high-frequency vibrations to liquefy soil and reduce driving resistance; suitable for loose to medium-dense soils.

- Diesel Hammers: Powered by diesel fuel; use a piston to strike the pile head; provide high impact energy for driving large piles.

- Hydraulic Hammers: Utilize hydraulic pressure to generate impact force; offer precise control and reduced noise compared to diesel hammers.

6. How do you ensure pile integrity and quality during the driving process?

- Visual Inspection: Regularly inspecting piles for any signs of damage, cracks, or deformation.

- Non-Destructive Testing (NDT): Using techniques such as ultrasonic testing or integrity testing to assess pile condition internally.

- Load Testing: Conducting static or dynamic load tests to verify the pile’s load-bearing capacity and structural integrity.

- Monitoring Driving Data: Recording and analyzing driving parameters, such as force, frequency, and penetration rate, to identify any anomalies or deviations.

7. Explain the importance of pile driving records and how you maintain them accurately.

Pile driving records provide valuable documentation of the driving process and are essential for:

- Project Verification: Records serve as evidence of the work performed and compliance with project specifications.

- Quality Control: They allow for monitoring of driving parameters and identification of any potential issues.

- Safety Audits: Records provide information on adherence to safety protocols and can assist in incident investigations.

- Insurance and Legal Purposes: They can serve as documentation in case of disputes or claims.

8. How do you collaborate with other construction trades and disciplines during a pile driving project?

Effective collaboration is crucial during pile driving projects, and I actively engage with other trades and disciplines, including:

- Engineers: Consulting with engineers to determine pile design, driving parameters, and quality control measures.

- Surveyors: Coordinating with surveyors to ensure accurate pile placement and alignment.

- Concrete Contractors: Liaising with concrete crews for pile cap construction and reinforcement.

- Safety Professionals: Working closely with safety personnel to maintain a safe and compliant work environment.

9. What are the ethical considerations and best practices you follow in your role as a Spike Driver?

- Safety First: Prioritizing the safety of myself, coworkers, and the public throughout the project.

- Quality Workmanship: Taking pride in delivering high-quality pile driving services that meet or exceed industry standards.

- Environmental Awareness: Minimizing environmental impact and adhering to regulations during pile driving operations.

- Respect for Others: Maintaining open communication, respecting diverse viewpoints, and fostering a positive work environment.

- Continuous Improvement: Actively seeking opportunities to enhance my skills, knowledge, and work practices.

10. How do you stay up-to-date with advancements and best practices in the pile driving industry?

- Industry Conferences and Workshops: Attending industry events to learn about new technologies, techniques, and regulations.

- Trade Publications and Journals: Subscribing to industry publications to stay informed about current trends and research.

- Online Resources and Training: Utilizing online platforms and training programs to enhance my knowledge and skills.

- Networking with Professionals: Connecting with other Spike Drivers, engineers, and industry experts to exchange ideas and learn from their experiences.

- Continuing Education: Pursuing additional certifications or training programs to broaden my knowledge and stay competitive.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spike Driver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spike Driver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Spike Driver is responsible for the safe and efficient operation of a spike driver machine. Their key responsibilities include:1. Spike Driving

Drive spike into ground using the proper driving force and techniques to ensure correct installation.

- Adjust the spike driver to the appropriate settings for the size and type of spike being driven.

- Position the spike driver over the desired location and secure it in place.

- Drive the spike into the ground by applying the appropriate force and maintaining a steady pace.

- Monitor the progress of the spike driving and make adjustments as needed to ensure accurate placement.

2. Equipment Maintenance

Inspect and maintain the spike driver machine to ensure it is in good working order.

- Conduct regular inspections of the spike driver machine, including checking oil levels, hydraulic fluid, and tire pressure.

- Perform routine maintenance tasks, such as cleaning and greasing the machine, and replacing worn or damaged parts.

- Troubleshoot and resolve minor mechanical issues with the spike driver machine.

- Report any major mechanical issues or repairs to the supervisor.

3. Worksite Safety

Promote and maintain a safe work environment by identifying and mitigating potential hazards.

- Identify and assess potential hazards on the worksite, such as overhead power lines, uneven ground, and heavy machinery.

- Establish and enforce safety procedures to minimize the risk of accidents or injuries.

- Use personal protective equipment (PPE) such as hard hats, safety glasses, and gloves while operating the spike driver machine.

- Follow all company safety policies and procedures.

4. Communication and Collaboration

Communicate effectively with colleagues, supervisors, and clients to ensure a smooth workflow.

- Communicate with colleagues to coordinate work tasks and ensure efficient use of resources.

- Report to the supervisor on the progress of work and any issues encountered.

- Liaise with clients to provide updates on project progress and address any concerns.

- Document and maintain records of work performed.

Interview Tips

To ace the interview for a Spike Driver position, consider the following tips:1. Research the Company and Position

Thoroughly research the company and the specific Spike Driver position to gain a deep understanding of their business, industry, and the role’s requirements.

- Visit the company’s website to learn about their history, mission, values, and recent news.

- Review the job description carefully to identify the essential responsibilities, qualifications, and skills required.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies in the field.

2. Highlight Relevant Experience and Skills

Emphasize your relevant experience, skills, and qualifications that align with the key job responsibilities of a Spike Driver.

- Quantify your accomplishments and provide specific examples of your experience driving spike machines or operating similar equipment.

- Showcase your knowledge of equipment maintenance and safety procedures.

- Highlight your ability to work independently and as part of a team, as well as your communication and interpersonal skills.

3. Prepare for Common Interview Questions

Prepare answers to common interview questions that may be asked for a Spike Driver position.

- Tell me about your experience driving spike machines or operating similar equipment.

- Describe your approach to ensuring worksite safety and following safety protocols.

- How do you handle troubleshooting and resolving mechanical issues with equipment?

- Give an example of a time when you had to work effectively as part of a team to complete a project.

4. Practice Your Answers

Practice your answers to interview questions out loud to gain confidence and fluency.

- Ask a friend or family member to conduct a mock interview with you.

- Record yourself answering interview questions and review your responses to identify areas for improvement.

- Time yourself to ensure you can provide concise and impactful answers within the allotted time frame.

5. Dress Professionally and Arrive on Time

Dress professionally and arrive on time for your interview to demonstrate respect for the interviewer and the company.

- Choose clothing that is clean, ironed, and appropriate for the work environment.

- Arrive at the interview location 15-20 minutes early to allow ample time to settle in and prepare.

- Bring a portfolio or notebook with copies of your resume and any relevant documents.

Next Step:

Now that you’re armed with the knowledge of Spike Driver interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Spike Driver positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini