Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dumper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

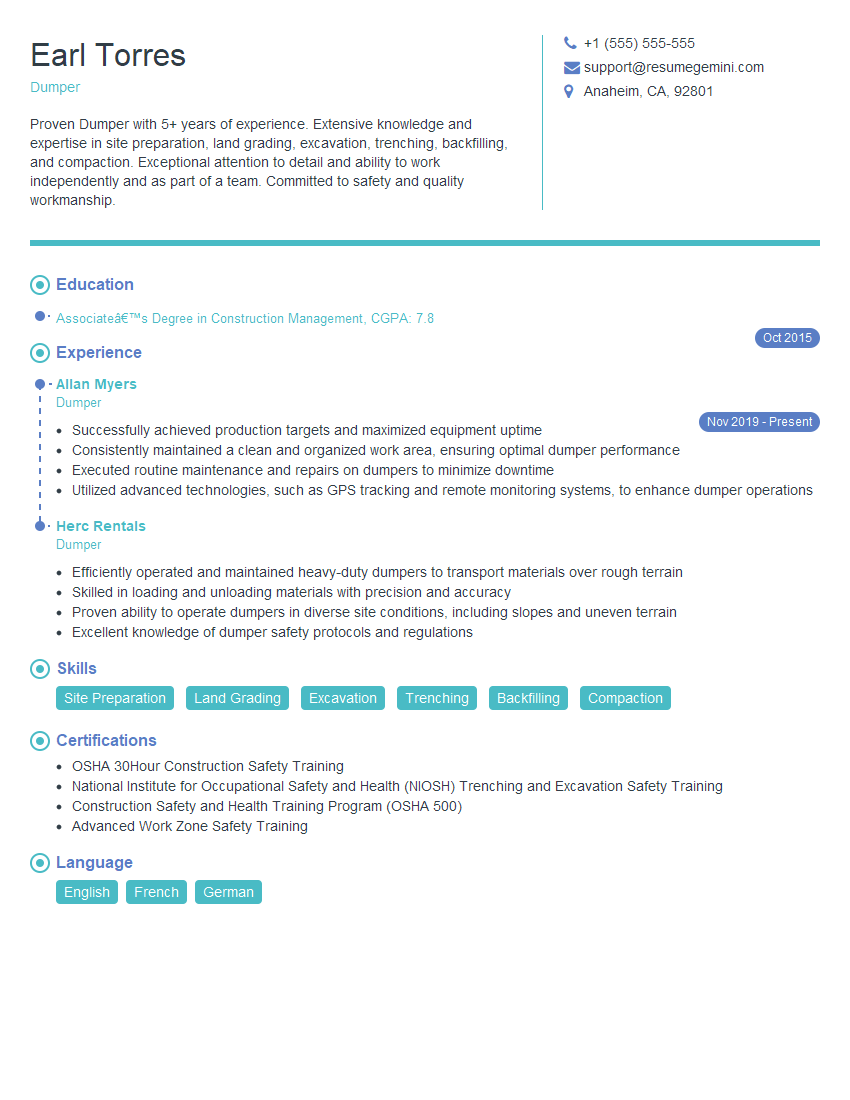

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dumper

1. Explain the different types of dumpers and their uses?

- Rigid Frame Dumpers: These dumpers have a rigid frame that connects the front and rear axles. They are designed for heavy-duty applications and can handle large payloads.

- Articulated Dumpers: These dumpers have a hinged frame that allows the front and rear axles to move independently. This gives them greater maneuverability, making them suitable for off-road conditions.

- Off-Highway Dumpers: These dumpers are specifically designed for use in mining and construction sites. They have large payloads and powerful engines, making them capable of handling heavy materials.

2. Describe the key components of a dumper and their functions?

Engine:

- Provides power to the dumper’s wheels and hydraulic systems.

- Determines the dumper’s speed, torque, and fuel efficiency.

Transmission:

- Transfers power from the engine to the wheels.

- Allows the dumper to change gears, providing the appropriate torque for different load and terrain conditions.

Hydraulic System:

- Powers the dumper’s steering, brakes, and bed lift mechanism.

- Provides control and precision during operation.

3. How do you ensure the safe operation of a dumper?

- Conduct regular inspections to identify and address any potential issues.

- Follow proper loading techniques to prevent overloading and uneven weight distribution.

- Be aware of the dumper’s surroundings, including overhead obstacles and pedestrians.

- Use proper safety gear, such as a seatbelt and hardhat.

- Receive adequate training and certification for dumper operation.

4. Explain the importance of preventive maintenance for dumpers?

- Reduces the risk of costly breakdowns and downtime.

- Extends the lifespan of the dumper by catching and addressing potential issues early on.

- Improves safety by ensuring that the dumper is in good operating condition.

- Reduces operating costs by minimizing the need for repairs and replacements.

5. Describe the different methods used to load and unload materials from a dumper?

- Front-End Loading: Using a front-end loader or excavator to scoop and load materials into the dumper’s bed.

- Rear-End Loading: Using a conveyor belt or chute to feed materials into the dumper’s bed from behind.

- Overhead Loading: Using a crane or hoist to lift and load materials into the dumper’s bed from above.

- Self-Loading: Some dumpers have built-in loading mechanisms, such as conveyor belts or scrapers, to load materials automatically.

6. How do you troubleshoot common dumper problems?

- Analyze the symptoms and identify potential causes.

- Refer to the dumper’s manual for specific troubleshooting guides.

- Check for loose connections, leaks, or damaged components.

- Test and inspect the electrical system, hydraulic system, and engine.

- Seek assistance from a qualified mechanic if necessary.

7. Discuss the environmental impact of dumper operations and how to mitigate it?

- Noise pollution: Implement soundproofing measures and use mufflers.

- Air pollution: Maintain engines properly and use low-emission fuels.

- Soil erosion: Use erosion control measures, such as vegetation and terraces.

- Water pollution: Prevent spills and leaks by using proper fueling and maintenance practices.

8. Explain the use of technology in modern dumpers?

- GPS tracking for monitoring dumper location and optimizing routes.

- Load-sensing systems for preventing overloading and ensuring proper weight distribution.

- Rearview cameras and sensors for enhancing visibility and safety.

- Automated transmission systems for smoother and more efficient operation.

9. Describe your experience in operating dumpers?

Project 1:

- Type of dumper used: Rigid frame dumper

- Payload handled: 20-30 tons

- Terrain and conditions: Off-road construction site

Project 2:

- Type of dumper used: Articulated dumper

- Payload handled: 10-15 tons

- Terrain and conditions: Steep and uneven mining site

10. How do you stay updated on the latest developments and best practices in dumper operations?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Consult with manufacturers and industry experts.

- Participate in online forums and discussion groups.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dumper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dumper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Dumper

Dumpers play a vital role in construction and mining operations, responsible for transporting and disposing of various materials. The key responsibilities of a Dumper include:

1. Material Handling

Collecting and transporting construction materials such as soil, gravel, rock, and debris to designated areas or disposal sites.

- Loading and unloading materials efficiently using heavy machinery.

- Ensuring safe and proper disposal of materials in accordance with environmental regulations.

2. Equipment Operation

Operating and maintaining a variety of dumper vehicles, including articulated dump trucks and off-highway trucks.

- Monitoring equipment performance, conducting regular inspections, and reporting any issues.

- Adhering to all safety protocols and operating procedures when handling heavy machinery.

3. Site Management

Assisting in maintaining a safe and organized worksite.

- Coordinating with other team members, supervisors, and contractors to ensure smooth operations.

- Following established policies and procedures for site management and waste disposal.

4. Communication and Documentation

Effectively communicating with colleagues, supervisors, and clients.

- Maintaining accurate records and documentation related to material handling and equipment operation.

- Reporting any incidents, accidents, or concerns promptly to the appropriate authorities.

Interview Preparation Tips for a Dumper Position

To ace the interview for a Dumper position, candidates should consider the following preparation tips:

1. Research the Company and Position

Thoroughly research the company, their industry, and the specific requirements of the Dumper role. This demonstrates your interest and commitment to the organization.

2. Practice Your Skills and Knowledge

Review your resume and highlight your relevant skills and experience in material handling, equipment operation, and site management. Practice answering common interview questions and anticipate technical questions about dumper operations.

3. Showcase Your Safety Mindset

Emphasize your commitment to safety and your understanding of industry regulations and best practices. Highlight your experience in operating heavy machinery and adhering to safety protocols.

4. Prepare for Site-Specific Questions

Research the specific project or site where the Dumper will be used. Familiarize yourself with the materials being handled, the terrain conditions, and any potential hazards.

5. Dress Appropriately and Be Punctual

Dress professionally and arrive on time for your interview. This conveys your respect for the interviewers and your interest in the position.

6. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewers. This demonstrates your engagement and interest in the role and the company.

7. Follow Up Professionally

After the interview, send a thank-you note to the interviewers reiterating your interest in the position and highlighting your qualifications. Follow up periodically to express your continued interest and inquire about the status of the application.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Dumper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.