Are you gearing up for an interview for a Carboy Filler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Carboy Filler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

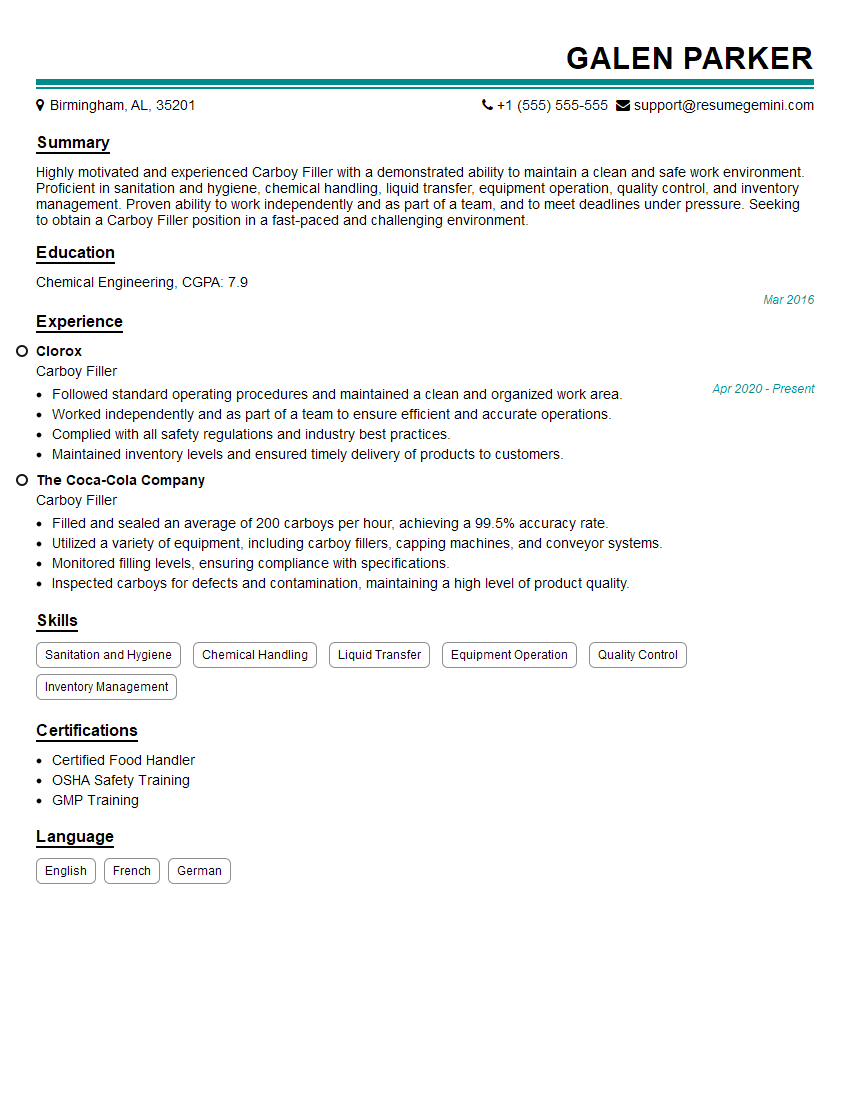

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carboy Filler

1. Explain the different types of carboys that are used in the beverage industry?

There are various types of carboys used in the beverage industry, including:

- Glass carboys: These are traditional carboys made of thick, clear glass. They are durable and easy to clean, but they can be heavy and fragile.

- Plastic carboys: These are lightweight and durable, making them easy to transport and handle. They are also less expensive than glass carboys.

- Stainless steel carboys: These are the most durable and sanitary type of carboy. They are corrosion-resistant and easy to clean, but they can be more expensive than other types of carboys.

2. What are the important factors to consider when selecting a carboy filling machine?

When selecting a carboy filling machine, several important factors should be considered, including:

- Capacity: The capacity of the machine refers to the number of carboys it can fill per hour.

- Accuracy: The accuracy of the machine refers to its ability to fill carboys to the desired level.

- Speed: The speed of the machine refers to how quickly it can fill carboys.

- Reliability: The reliability of the machine refers to its ability to operate consistently without breakdowns.

- Ease of use: The ease of use of the machine refers to how easy it is to operate and maintain.

3. Describe the process of filling a carboy using a manual filling machine?

The process of filling a carboy using a manual filling machine typically involves the following steps:

- Sanitize the carboy: Before filling, the carboy should be sanitized to prevent contamination.

- Position the carboy: The carboy should be positioned under the filling nozzle.

- Fill the carboy: The filling nozzle should be inserted into the carboy, and the filling valve should be opened.

- Monitor the filling level: The filling level should be monitored to ensure that the carboy is filled to the desired level.

- Close the filling valve: Once the carboy is filled, the filling valve should be closed.

- Remove the filling nozzle: The filling nozzle should be removed from the carboy.

4. What are the safety precautions that should be taken when operating a carboy filling machine?

When operating a carboy filling machine, several safety precautions should be taken, including:

- Wear appropriate safety gear: This includes gloves, safety glasses, and a lab coat.

- Follow the manufacturer’s instructions: The manufacturer’s instructions should be followed carefully to ensure safe operation of the machine.

- Be aware of the potential hazards: The potential hazards of operating a carboy filling machine should be known, and steps should be taken to avoid them.

- Inspect the machine regularly: The machine should be inspected regularly to ensure that it is in good working order.

- Report any problems immediately: Any problems with the machine should be reported to a supervisor immediately.

5. What are the common problems that can occur when filling carboys?

Several common problems can occur when filling carboys, including:

- Overfilling: Overfilling can occur if the filling level is not monitored carefully.

- Underfilling: Underfilling can occur if the filling valve is not opened fully or if the filling time is too short.

- Leaking: Leaking can occur if the carboy is not properly sealed or if the filling nozzle is not properly inserted.

- Contamination: Contamination can occur if the carboy is not sanitized before filling or if the filling equipment is not properly cleaned.

- Breakage: Breakage can occur if the carboy is not handled carefully or if it is dropped.

6. How can you troubleshoot common problems that occur when filling carboys?

Common problems that occur when filling carboys can be troubleshooted by:

- Overfilling: Overfilling can be prevented by monitoring the filling level carefully and by adjusting the filling valve accordingly.

- Underfilling: Underfilling can be prevented by opening the filling valve fully and by increasing the filling time.

- Leaking: Leaking can be prevented by ensuring that the carboy is properly sealed and that the filling nozzle is properly inserted.

- Contamination: Contamination can be prevented by sanitizing the carboy before filling and by cleaning the filling equipment regularly.

- Breakage: Breakage can be prevented by handling the carboy carefully and by avoiding dropping it.

7. What are the different types of filling heads that are used in carboy filling machines?

There are several different types of filling heads that are used in carboy filling machines, including:

- Gravity filling heads: Gravity filling heads use gravity to fill carboys. They are simple and inexpensive, but they can be slow.

- Pressure filling heads: Pressure filling heads use pressure to fill carboys. They are faster than gravity filling heads, but they can be more expensive.

- Vacuum filling heads: Vacuum filling heads use a vacuum to fill carboys. They are the fastest and most accurate type of filling head, but they can be the most expensive.

8. How can you calibrate a carboy filling machine?

A carboy filling machine can be calibrated by:

- Filling a carboy with a known weight of liquid: The weight of the filled carboy can be compared to the known weight of liquid to determine the accuracy of the filling machine.

- Using a flow meter: A flow meter can be used to measure the flow rate of liquid through the filling machine. The flow rate can be adjusted to achieve the desired filling level.

9. What are the different types of maintenance that are required for a carboy filling machine?

Different types of maintenance that are required for a carboy filling machine include:

- Daily maintenance: Daily maintenance includes cleaning the machine, inspecting the filling heads, and checking the fluid levels.

- Weekly maintenance: Weekly maintenance includes lubricating the machine, checking the belts and hoses, and inspecting the electrical components.

- Monthly maintenance: Monthly maintenance includes performing a more thorough inspection of the machine, including checking the bearings, seals, and gaskets.

- Yearly maintenance: Yearly maintenance includes a complete overhaul of the machine, including replacing any worn or damaged parts.

10. What are the different types of materials that are used to make carboys?

Different types of materials that are used to make carboys include:

- Glass: Glass carboys are traditional and durable, but they can be heavy and fragile.

- Plastic: Plastic carboys are lightweight and durable, but they can be less resistant to chemicals and heat.

- Stainless steel: Stainless steel carboys are durable and corrosion-resistant, but they can be more expensive than other types of carboys.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carboy Filler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carboy Filler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Carboy Fillers are responsible for the safe and efficient filling of carboys with various liquids, typically in a manufacturing or industrial setting. Here are the key job responsibilities of a Carboy Filler:

1. Operate and Maintain Filling Equipment

Setting up, operating, and maintaining automated or semi-automated filling machines to fill carboys with liquids to the required levels.

- Monitoring equipment performance to ensure smooth operation.

- Performing routine maintenance and calibrations to keep equipment running efficiently.

2. Inspect and Prepare Carboys

Inspecting carboys for damage or contamination before filling. Cleaning and sanitizing carboys to meet required standards.

- Labeling carboys with the correct product information.

- Ensuring that carboys are properly sealed before filling.

3. Load and Unload Carboys

Loading empty carboys into the filling machine and unloading filled carboys using forklifts or other equipment.

- Positioning carboys correctly for filling.

- Handling carboys with care to minimize damage.

4. Monitor Filling Process

Monitoring the filling process to ensure that carboys are filled accurately and without spills.

- Observing liquid levels and adjusting settings as needed.

- Inspecting filled carboys for leaks or damage.

5. Maintain Safety and Quality

Adhering to all safety protocols and regulations.

- Wearing appropriate personal protective equipment (PPE).

- Maintaining a clean and organized work area.

- Following established quality control procedures.

Interview Tips

To help candidates ace their Carboy Filler interview, here are a few tips and preparation hacks:

1. Research the Company and Position

Thoroughly research the company and the specific role to gain a good understanding of their industry, products, culture, and expectations.

- Visit the company website, read about their mission, values, and services.

- Check out the LinkedIn profile of the company and its employees.

2. Practice Common Interview Questions

Prepare for common interview questions related to the job responsibilities, such as:

- Tell me about your experience operating and maintaining filling equipment.

- How do you ensure the accuracy and quality of the filling process?

- Describe your approach to maintaining a safe and organized work area.

3. Highlight Relevant Skills and Experience

In your answers, emphasize skills and experiences that are directly relevant to the job requirements.

- Use specific examples to demonstrate your abilities in operating filling equipment, inspecting carboys, and adhering to safety protocols.

- Quantify your accomplishments whenever possible, using numbers and metrics to showcase your impact.

4. Be Punctual and Professional

Arrive for your interview on time and dress professionally. Being punctual and well-presented demonstrates respect and attention to detail.

- Plan your route in advance and allow extra time for unforeseen circumstances.

- Dress in business attire or the appropriate uniform for the industry.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Carboy Filler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.