Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Belt Cleaner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

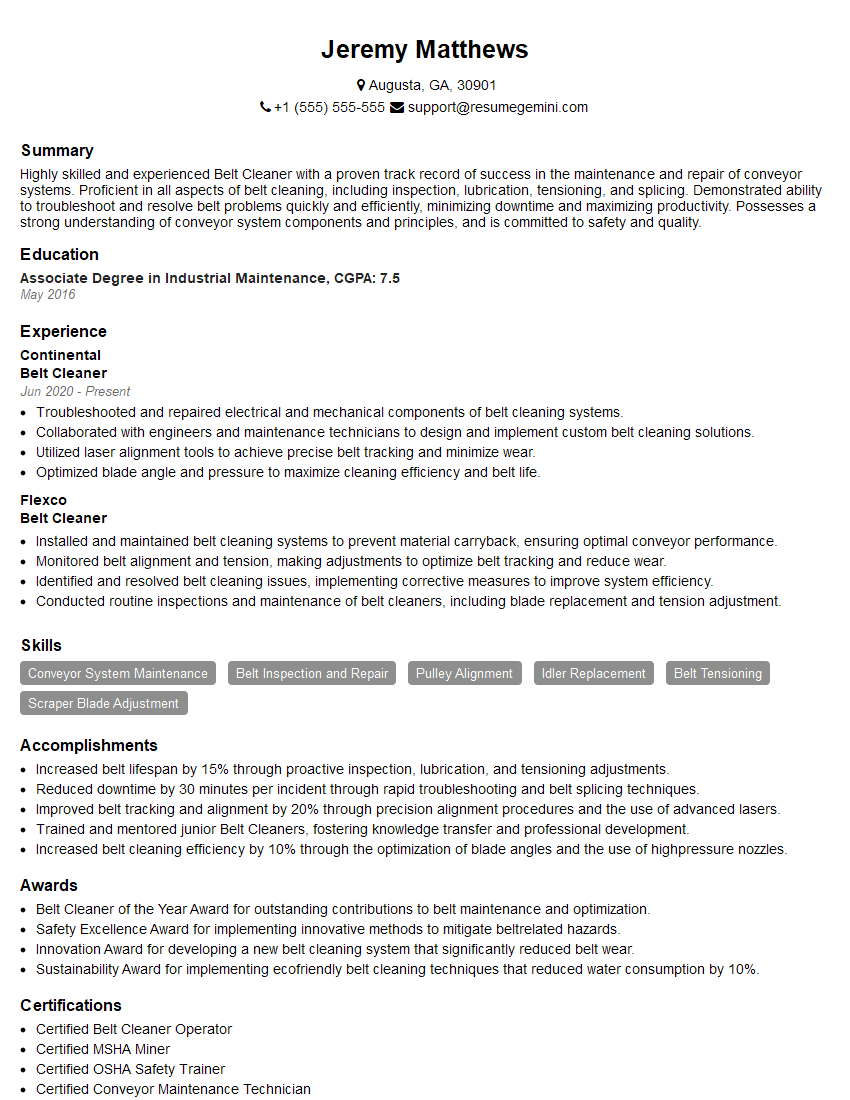

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Belt Cleaner

1. What are the different types of belt cleaners and their applications?

There are various types of belt cleaners, each designed for specific applications. Here are some common types:

- Primary cleaners: These are installed at the head pulley and remove the majority of the material carryback.

- Secondary cleaners: These are placed after the primary cleaners and remove any remaining carryback.

- Pre-cleaners: These are used before the primary cleaners to remove large lumps of material.

- Scrapers: These are used to remove sticky or wet materials from the belt.

- Brushes: These are used to clean belts with fine or powdery materials.

2. What are the factors to consider when selecting a belt cleaner?

Material characteristics:

- Type of material (e.g., coal, ore, grain)

- Particle size and moisture content

- Adhesiveness and abrasiveness

Belt characteristics:

- Belt width and speed

- Belt tension and alignment

- Belt material (e.g., rubber, fabric)

Operating conditions:

- Temperature and humidity

- Dust and dirt levels

- Space constraints

3. How do you maintain and troubleshoot belt cleaners?

Regular maintenance is crucial for optimal performance of belt cleaners:

- Inspection: Regularly inspect the cleaners for wear, damage, or alignment issues.

- Cleaning: Clean the cleaners periodically to remove accumulated material and prevent clogging.

- Adjustment: Ensure the cleaners are properly aligned and adjusted to the belt to maximize cleaning efficiency.

Troubleshooting common issues:

- Poor cleaning efficiency: Check for worn or damaged blades, incorrect alignment, or excessive material build-up.

- Belt damage: Ensure the cleaners are not too aggressive or misaligned, causing damage to the belt.

- Excessive wear: Inspect for abrasive materials or improper tension on the cleaners.

4. What materials are used in the construction of belt cleaners?

- Blades: Tungsten carbide, polyurethane, rubber, or ceramic

- Frames: Stainless steel, aluminum, or composite materials

- Springs: Steel or stainless steel

- Bearings: Sealed ball bearings or sleeve bearings

5. Describe the benefits of using belt cleaners in conveyor systems.

- Reduced carryback: Belt cleaners remove material carryback, minimizing spillage and dust generation.

- Belt protection: They prevent material buildup on the belt, protecting it from damage and extending its lifespan.

- Increased productivity: By reducing carryback, belt cleaners ensure smooth belt operation, maximizing throughput and reducing downtime.

- Improved safety: Cleaner belts reduce the risk of accidents caused by material spillage or dust inhalation.

- Environmental compliance: Belt cleaners help meet environmental regulations by minimizing fugitive emissions and dust pollution.

6. Explain the working principle of a centrifugal belt cleaner.

Centrifugal belt cleaners utilize centrifugal force to remove material from the belt:

- Rotating cylinder: A high-speed rotating cylinder creates a centrifugal force that flings material away from the belt.

- Material discharge: The displaced material is discharged into a collection hopper or chute.

- Belt cleaning: The belt is effectively cleaned as it passes through the centrifugal field.

7. What are the different types of materials that can be cleaned by belt cleaners?

Belt cleaners are versatile and can effectively clean a wide range of materials, including:

- Dry bulk materials (e.g., coal, ore, grain, sand)

- Wet or sticky materials (e.g., clay, mud, food products)

- Fine or powdery materials (e.g., flour, cement, dust)

- Abrasive materials (e.g., rocks, gravel, metal shavings)

- Fibrous materials (e.g., wood chips, paper pulp)

8. What are the advantages and disadvantages of using air-operated belt cleaners?

Advantages:

- Powerful cleaning: Air-operated cleaners provide high-force blasts of air for effective debris removal.

- Gentle on belts: The air stream is non-abrasive, minimizing belt wear.

- No moving parts: They require minimal maintenance and have a long lifespan.

Disadvantages:

- Air consumption: Air-operated cleaners require a constant supply of compressed air, which can increase operating costs.

- Noise levels: The air blasts can generate noise pollution.

- Not suitable for wet or sticky materials: Air cleaners are ineffective on materials that adhere to the belt.

9. How do you determine the optimum blade angle for a belt cleaner?

The optimum blade angle for a belt cleaner depends on several factors:

- Material type: Different materials require different angles to achieve maximum cleaning efficiency.

- Belt speed: Higher belt speeds require a smaller blade angle to prevent material from being pushed back onto the belt.

- Material flow rate: Heavy material flow rates demand a larger blade angle for effective removal.

To determine the optimum angle, it is recommended to conduct field trials or consult with the manufacturer’s guidelines.

10. Discuss the safety considerations when working with belt cleaners.

- Lockout/tagout procedures: Ensure all power sources are isolated before servicing or adjusting belt cleaners.

- Proper PPE: Wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection.

- Avoid contact with moving parts: Keep hands and clothing away from rotating blades or other moving components.

- Regular inspections: Regularly inspect belt cleaners for damage or loose components to prevent accidents.

- Training: Ensure all personnel handling belt cleaners are properly trained on safety protocols and operating procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Belt Cleaner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Belt Cleaner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Belt Cleaner, you will be responsible for maintaining and cleaning industrial belts used in various manufacturing and processing operations. Your primary duties will include:

1. Belt Cleaning and Maintenance

Ensuring belts are clean and free of debris, dust, or contaminants using specialized cleaning tools and techniques.

- Inspecting belts regularly for signs of wear, damage, or buildup.

- Cleaning belts using brushes, scrapers, or vacuum cleaners.

2. Belt Inspection and Repair

Identifying and repairing minor belt damage to prevent equipment downtime and maintain belt longevity.

- Identifying worn or damaged areas on belts.

- Performing minor repairs, such as patching or splicing, to restore belt functionality.

3. Equipment Maintenance

Maintaining and servicing belt cleaning equipment to ensure optimal performance and prevent breakdowns.

- Inspecting and cleaning cleaning tools and equipment.

- Performing routine maintenance tasks, such as lubrication and filter replacement.

4. Safety and Compliance

Adhering to established safety protocols and maintaining a clean and organized work environment.

- Wearing appropriate safety gear, such as gloves and eye protection.

- Following established cleaning and maintenance procedures.

Interview Tips

Preparing for an interview for a Belt Cleaner position can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Gather information about the company, its industry, and the specific role you are applying for. This will help you demonstrate your understanding of the position and how your skills align.

- Visit the company’s website and social media pages.

- Read industry articles and news to stay up-to-date on the latest trends.

2. Highlight Your Relevant Skills and Experience

Emphasize your prior experience in belt cleaning and maintenance. Quantify your accomplishments whenever possible, using specific metrics and results.

- Discuss the types of belts and cleaning equipment you have worked with.

- Mention any certifications or training you have received in belt cleaning.

3. Demonstrate Your Safety Awareness

Safety is paramount in industrial environments. Highlight your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Discuss your experience with safety procedures and PPE.

- Emphasize your attention to detail and ability to identify potential hazards.

4. Prepare for Common Interview Questions

Research common interview questions for Belt Cleaner positions. Prepare answers that showcase your skills, experience, and fit for the role.

- Tell me about your experience with belt cleaning and maintenance.

- How do you prioritize safety in your work?

- What are your strengths and weaknesses as a Belt Cleaner?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Belt Cleaner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!