Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rigging Up Man position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

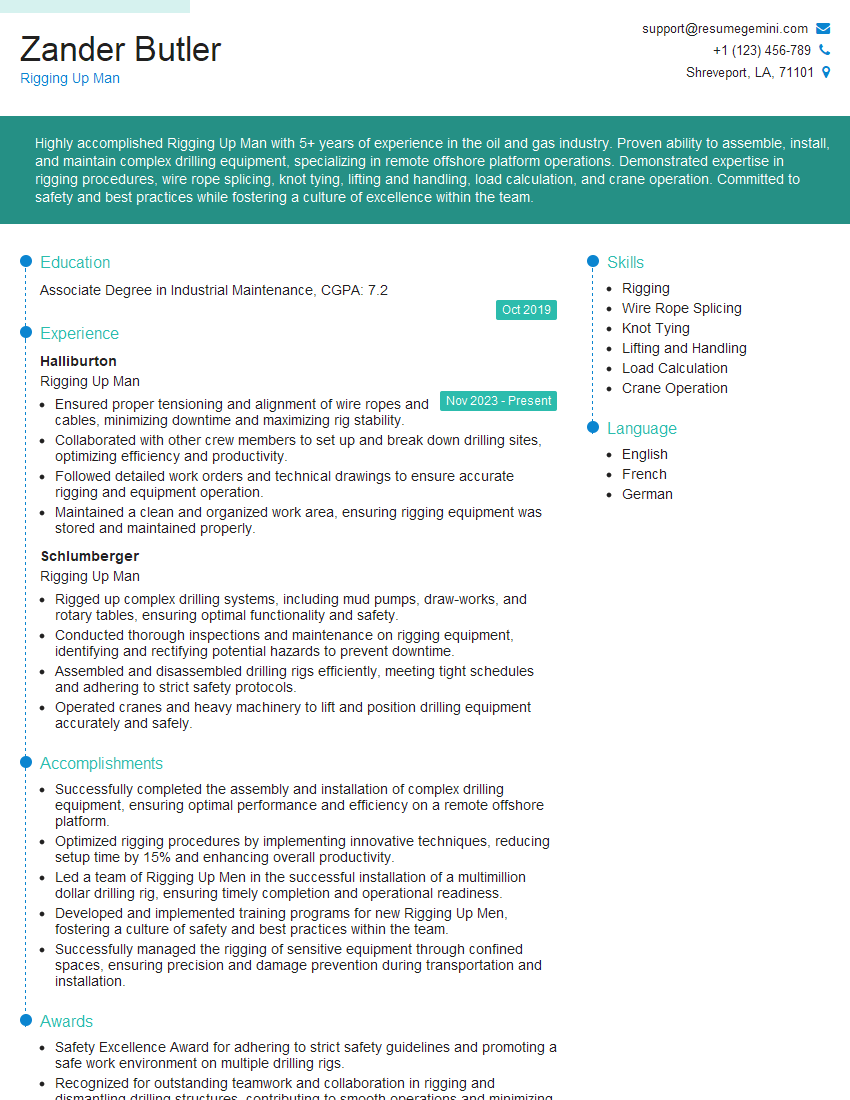

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rigging Up Man

1. What are the key responsibilities of a Rigging Up Man?

The key responsibilities of a Rigging Up Man include:

- Erecting, dismantling, and maintaining scaffolding and other rigging equipment

- Inspecting rigging equipment for safety and compliance

- Operating cranes and other lifting equipment

- Supervising and training other rigging personnel

- Ensuring that all rigging operations are conducted safely and efficiently

2. What are the minimum qualifications for a Rigging Up Man?

The minimum qualifications for a Rigging Up Man typically include:

- A high school diploma or equivalent

- At least two years of experience in the rigging industry

- A valid driver’s license

- A strong understanding of safety regulations

- Excellent physical condition

3. What are the different types of rigging systems?

There are many different types of rigging systems, each with its own unique advantages and disadvantages. Some of the most common types of rigging systems include:

- Suspended scaffolds

- Supported scaffolds

- Cranes

- Hoists

- Gin poles

- Overhead cranes

- Gantry cranes

4. What are the factors to consider when choosing a rigging system?

When choosing a rigging system, it is important to consider the following factors:

- The type of work being performed

- The weight of the load

- The height of the work area

- The available space

- The budget

5. What are the safety precautions that must be taken when working with rigging equipment?

When working with rigging equipment, it is important to take the following safety precautions:

- Always inspect rigging equipment before use

- Never overload rigging equipment

- Always use proper lifting techniques

- Be aware of your surroundings and potential hazards

- Follow all safety regulations

6. What are the common causes of rigging accidents?

The common causes of rigging accidents include:

- Equipment failure

- Human error

- Improper use of equipment

- Insufficient training

- Lack of supervision

7. What are the steps involved in rigging a load?

The steps involved in rigging a load typically include:

- Preparing the load for lifting

- Selecting the appropriate rigging equipment

- Attaching the rigging equipment to the load

- Lifting the load

- Positioning the load

- Securing the load

8. What are the different types of load handling equipment?

There are many different types of load handling equipment, each with its own unique advantages and disadvantages. Some of the most common types of load handling equipment include:

- Cranes

- Hoists

- Forklifts

- Conveyors

- Automated guided vehicles (AGVs)

9. What are the factors to consider when selecting load handling equipment?

When selecting load handling equipment, it is important to consider the following factors:

- The type of load being handled

- The weight of the load

- The distance the load needs to be moved

- The available space

- The budget

10. What are the safety precautions that must be taken when working with load handling equipment?

When working with load handling equipment, it is important to take the following safety precautions:

- Always inspect load handling equipment before use

- Never overload load handling equipment

- Always use proper lifting techniques

- Be aware of your surroundings and potential hazards

- Follow all safety regulations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rigging Up Man.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rigging Up Man‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rigging Up Man plays a crucial role in ensuring the safe and efficient operation of oil rigs and drilling platforms. Their key responsibilities encompass a wide range of tasks, including:

1. Rigging and Dismantling Equipment

Rigging Up Men are responsible for assembling, erecting, disassembling, and dismantling various equipment and structures on the drilling platform. This includes cranes, derricks, drilling rigs, and other machinery crucial for the operation.

- Assembling equipment: They follow blueprints and specifications to put together complex equipment, ensuring all components are properly aligned and secured.

- Erecting structures: Rigging Up Men work at heights to erect drilling rigs, derricks, and other structures, using specialized tools and techniques to ensure stability and safety.

- Disassembling equipment: When drilling operations are complete or when equipment needs maintenance, Rigging Up Men disassemble it safely and efficiently, following proper procedures to prevent accidents.

- Dismantling structures: They dismantle drilling rigs and other structures, ensuring that all components are properly labeled and stored for future use or disposal.

2. Maintaining and Inspecting Equipment

Rigging Up Men are responsible for maintaining and inspecting equipment to ensure it is in good working order and meets safety standards. They perform regular checks, identify potential issues, and carry out repairs or adjustments as needed.

- Regular maintenance: They conduct routine maintenance tasks, such as lubricating moving parts, checking fluid levels, and tightening bolts, to keep equipment running smoothly.

- Inspections: Rigging Up Men perform thorough inspections of equipment before each use and after any maintenance or repairs, ensuring it meets safety standards and is ready for operation.

- Identifying issues: They are trained to identify potential issues with equipment and take prompt action to prevent accidents or breakdowns.

- Repairs and adjustments: Rigging Up Men have the skills to perform minor repairs and adjustments to equipment, ensuring it is operating at peak efficiency.

3. Operating Cranes and Hoisting Equipment

Rigging Up Men are skilled in operating cranes and hoisting equipment to lift and move heavy loads safely and efficiently. They ensure that all loads are properly secured and that lifting operations are conducted according to established safety protocols.

- Crane operation: They operate cranes to lift and move heavy equipment, materials, and structures, following hand signals or instructions from a designated signal person.

- Hoisting equipment operation: Rigging Up Men use hoists and other lifting equipment to move loads vertically, ensuring that all equipment is properly secured and operated safely.

- Load securing: They are responsible for properly securing loads to prevent accidents or damage during lifting operations.

- Safety protocols: Rigging Up Men adhere to established safety protocols when operating cranes and hoisting equipment, ensuring the safety of themselves, coworkers, and the equipment.

4. Working at Heights

Rigging Up Men frequently work at significant heights, requiring them to have excellent balance, coordination, and a strong sense of safety. They are trained in fall protection techniques and use appropriate safety equipment to minimize risks.

- Working on elevated structures: They work on elevated structures, such as drilling rigs and derricks, to assemble, dismantle, and maintain equipment.

- Fall protection: Rigging Up Men are trained in fall protection techniques and use fall arrest systems, lanyards, and harnesses to prevent accidents while working at heights.

- Safety equipment: They wear appropriate safety equipment, such as hard hats, safety glasses, and gloves, to protect themselves from potential hazards.

- Risk assessment: Rigging Up Men assess risks when working at heights and take necessary precautions to minimize the likelihood of accidents.

Interview Tips

Preparing for an interview for a Rigging Up Man position requires thorough research and a well-structured approach. Here are some tips to help you ace the interview:

1. Research the Company and Industry:

Take time to research the oil and gas industry, as well as the specific company you are applying to. Understand their operations, safety protocols, and any recent developments or projects they are involved in.

- Company website: Visit the company’s website to learn about their history, mission, values, and current projects.

- Industry publications: Read industry publications and news articles to stay updated on the latest advancements and trends in the oil and gas sector.

2. Highlight your Technical Skills and Experience:

Emphasize your technical skills and experience in rigging, equipment maintenance, and crane operation. Provide specific examples of your work and the results you achieved.

- Skills demonstration: During the interview, be prepared to demonstrate your skills in rigging, equipment maintenance, and crane operation through storytelling or hypothetical situations.

- Quantify your accomplishments: Use numbers and metrics to quantify your accomplishments, showcasing the impact of your work on safety, efficiency, or cost savings.

3. Demonstrate your Safety Consciousness:

Rigging Up Men must prioritize safety in all aspects of their work. Highlight your understanding of safety protocols, your commitment to following them, and your experience in working safely at heights.

- Safety certifications: Obtain relevant safety certifications, such as OSHA or industry-specific certifications, to demonstrate your commitment to safety.

- Safety anecdotes: Share anecdotes from your previous work experience that showcase your safety consciousness and proactive approach to hazard identification and mitigation.

4. Prepare for Common Interview Questions:

Research common interview questions for Rigging Up Men and prepare your answers thoroughly. Practice answering them out loud to improve your confidence and delivery.

- Tell me about a time you faced a challenging rigging situation and how you overcame it: Prepare an example that highlights your problem-solving skills, technical expertise, and ability to work under pressure.

- How do you prioritize safety when working at heights: Explain your understanding of fall protection techniques, safety equipment, and risk assessment procedures.

- What are your strengths and weaknesses as a Rigging Up Man: Be honest about your strengths and weaknesses, but focus on presenting your strengths as they relate to the job requirements.

Next Step:

Now that you’re armed with the knowledge of Rigging Up Man interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rigging Up Man positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini