Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cupola Hoist Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cupola Hoist Operator so you can tailor your answers to impress potential employers.

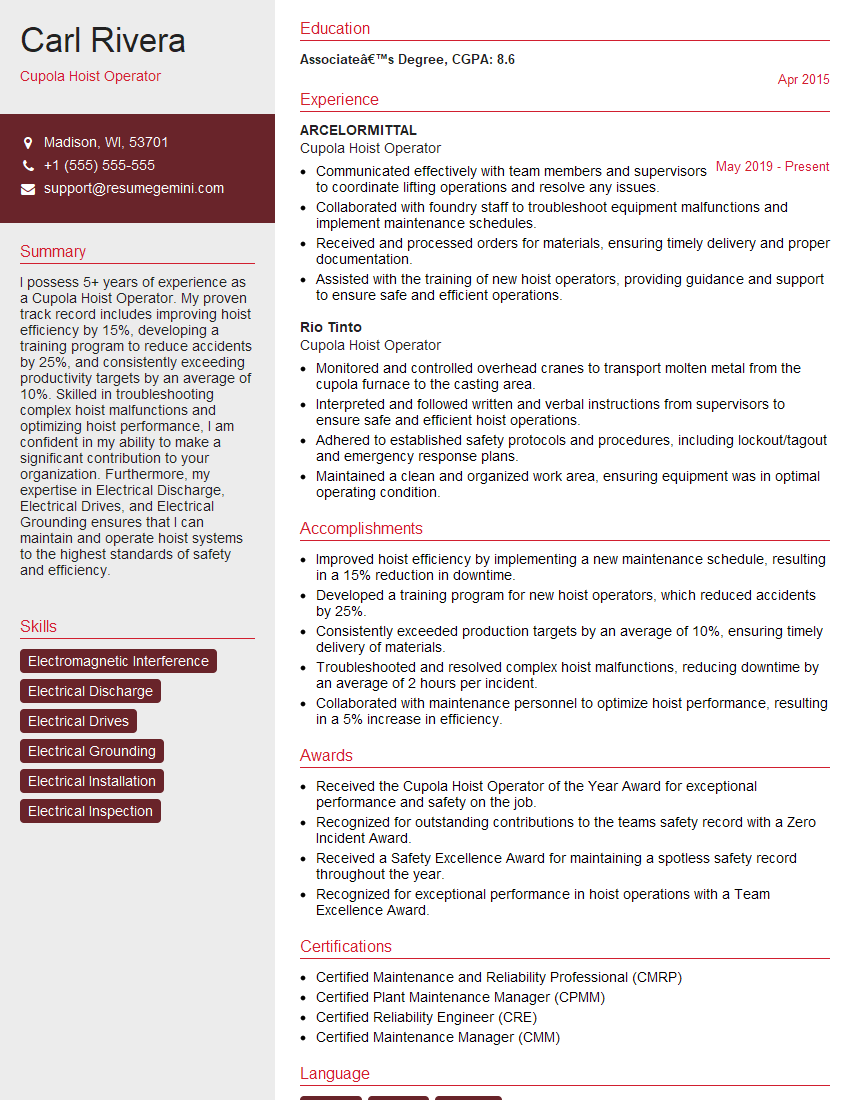

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cupola Hoist Operator

1. What are the key responsibilities of a Cupola Hoist Operator?

As a Cupola Hoist Operator, my key responsibilities include:

- Operating and maintaining overhead cranes to transport materials and equipment within the cupola area.

- Monitoring and controlling the pouring of molten metal from the cupola into ladles or other containers.

- Ensuring the safe and efficient movement of materials and equipment throughout the casting process.

2. How do you ensure the safety of yourself and others when operating a cupola hoist?

Maintaining a Safe Work Environment

- Conduct regular inspections of the hoist and its components.

- Follow established safety procedures and protocols.

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, and gloves.

Communication and Coordination

- Establish clear communication channels with other operators and personnel.

- Coordinate with ground personnel to ensure safe movement of materials.

- Inform supervisors of any potential hazards or unsafe conditions.

3. Describe the different types of loads you have experience handling with a cupola hoist.

Throughout my experience as a Cupola Hoist Operator, I have handled various types of loads, including:

- Molten metal ladles

- Scrap metal charges

- Raw materials (e.g., coke, limestone, ferroalloys)

- Molds and castings

- Maintenance and repair equipment

4. How do you handle and transport molten metal safely?

Handling and transporting molten metal safely requires meticulous attention to detail and adherence to established procedures:

- Verify that the ladle is properly lined and preheated to prevent metal sticking.

- Coordinate with the crane operator to ensure a smooth and controlled pour.

- Monitor the temperature of the molten metal and adjust pouring rates accordingly.

- Follow established safety protocols for spill containment and emergency response.

5. Describe the maintenance procedures you follow to keep the cupola hoist in optimal condition.

- Daily Inspections: Check for any visible damage, leaks, or loose connections.

- Weekly Inspections: Lubricate moving parts, inspect brakes and controllers, and test limit switches.

- Monthly Inspections: Conduct thorough examinations of the hoist, including electrical components, ropes, and hooks.

- Regular Maintenance Tasks: Grease bearings, replace worn parts, and calibrate sensors as needed.

6. How do you troubleshoot and resolve common problems with a cupola hoist?

Troubleshooting and resolving common problems with a cupola hoist requires a systematic approach:

Electrical Issues

- Check for loose connections, blown fuses, or faulty wiring.

- Verify that the power supply is stable and within specifications.

Mechanical Issues

- Inspect for worn gears, bearings, or brake pads.

- Check for any blockages or obstructions in the hoisting mechanism.

Hydraulic Issues

- Monitor hydraulic fluid levels and pressure.

- Inspect for leaks or damage to hoses and cylinders.

7. How do you calculate the weight of a load and ensure it does not exceed the hoist’s capacity?

Calculating the weight of a load accurately is crucial for safe operation. I follow these steps:

- Determine the density of the material being lifted.

- Measure the volume of the load.

- Multiply the density by the volume to obtain the weight.

- Compare the calculated weight to the hoist’s rated capacity and never exceed it.

8. Describe your experience with working in a team environment. How do you contribute to team success?

Working effectively in a team environment is essential in this role. I contribute to team success through:

- Communication: Share information openly and actively listen to others.

- Cooperation: Willingly assist colleagues and support their tasks.

- Coordination: Collaborate to ensure smooth workflow and avoid conflicts.

- Conflict Resolution: Approach disagreements constructively and seek mutually acceptable solutions.

9. Explain how you prioritize tasks and manage your time effectively.

Prioritizing tasks and managing time effectively are crucial for efficient operation. I use these strategies:

- Prioritization Matrix: Categorize tasks based on urgency and importance.

- Time Management Techniques: Utilize tools such as to-do lists and calendars.

- Delegation: When appropriate, delegate tasks to others to optimize workload.

- Flexibility: Adapt to changing priorities and adjust schedules accordingly.

10. How do you stay updated with advancements and best practices in the cupola hoist industry?

Continuous learning and staying abreast of industry advancements are vital for professional growth. I engage in these practices:

- Industry Publications: Read trade magazines and attend industry conferences.

- Online Resources: Utilize online platforms to access technical articles and webinars.

- Networking: Connect with other professionals and share knowledge.

- Training and Development: Participate in training programs and workshops to enhance skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cupola Hoist Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cupola Hoist Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cupola Hoist Operators play a vital role in foundries, operating and maintaining hoists and cranes to transport molten metal. Their main responsibilities include:

1. Hoist Operation

Operate hoists and cranes to lift, move, and pour molten metal from cupolas into ladles or other containers.

- Control hoist movements using levers, buttons, or joysticks.

- Ensure smooth and precise movement of loads.

2. Crane Maintenance

Perform routine inspections and maintenance on hoists and cranes, including lubrication, greasing, and minor repairs.

- Identify and report any potential issues or malfunctions.

- Participate in scheduled maintenance and repair work.

3. Safety Management

Adhere to strict safety protocols to minimize risks.

- Wear appropriate personal protective equipment (PPE).

- Inspect slings, chains, and hooks for damage.

- Follow load weight limits and avoid overloading.

4. Communication and Coordination

Communicate effectively with other team members, including foundry operators, supervisors, and maintenance personnel.

- Coordinate hoist movements to ensure efficient and safe operations.

- Report any concerns or issues promptly.

Interview Tips

To ace the interview for a Cupola Hoist Operator position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the foundry’s operations, products, and safety regulations. This will demonstrate your interest and knowledge of the field.

- Visit the company’s website to learn about their history, services, and culture.

- Read industry publications and articles to stay informed about best practices.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating hoists and cranes, as well as any certifications or training you have received. Quantify your accomplishments whenever possible.

- Describe specific instances where you successfully lifted and transported heavy loads.

- Mention any safety protocols or procedures you have implemented or followed.

3. Demonstrate Safety Consciousness

Safety is paramount in foundries. Highlight your commitment to following safety protocols and ensuring the well-being of yourself and others.

- Explain your understanding of the potential hazards associated with hoist operations.

- Discuss the importance of wearing PPE and following proper lifting techniques.

4. Show Enthusiasm and Willingness to Learn

Express your passion for operating hoists and cranes and your willingness to learn and improve your skills.

- Ask questions about the company’s safety policies and training opportunities.

- Indicate your eagerness to contribute to the team’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cupola Hoist Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!