Feeling lost in a sea of interview questions? Landed that dream interview for Building Rigger but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Building Rigger interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

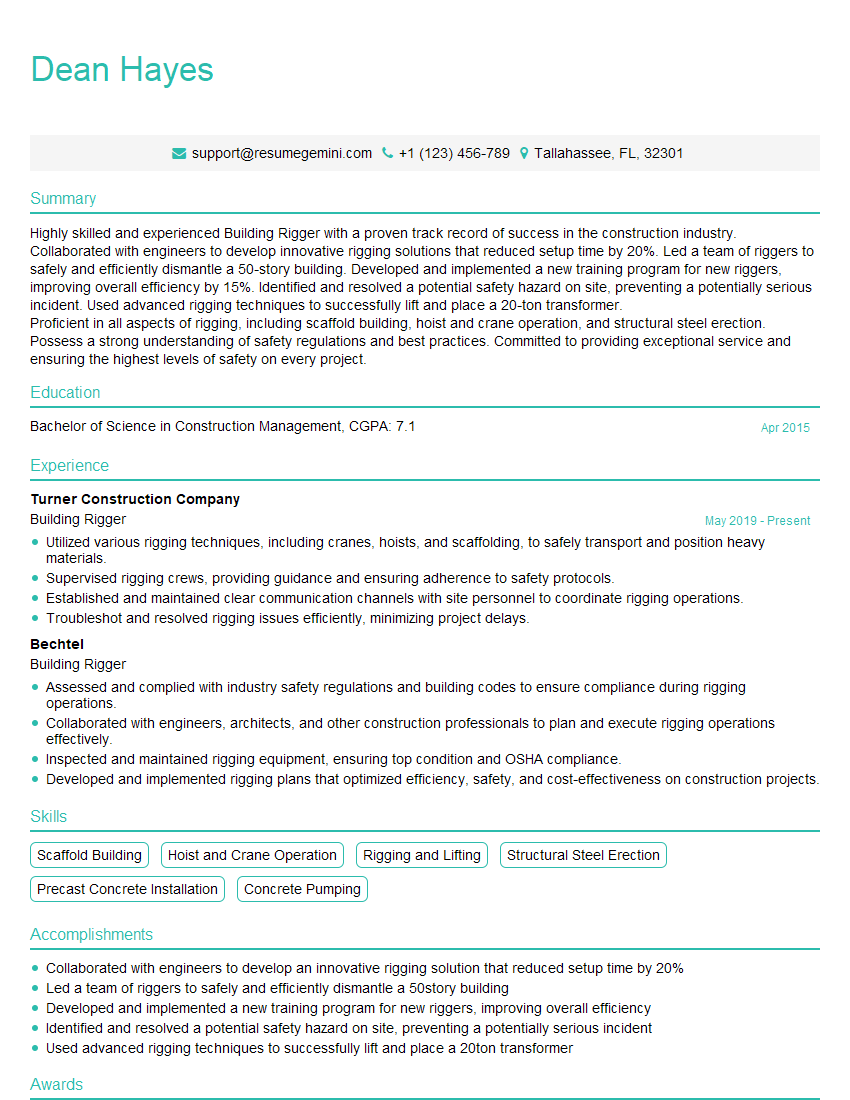

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Building Rigger

1. Describe the types of hoists used in building rigging and their applications?

- Hydraulic Hoists: Used for heavy lifting, precise control, and operation in confined spaces.

- Electric Hoists: Provide high-speed lifting, reliable operation, and can be used for a variety of lifting applications.

- Chain Hoists: Manual or electric, used for lifting lighter loads, ideal for applications where portability is required.

- Crane Hoists: Mounted on cranes, designed for lifting heavy and bulky items, and providing extensive reach and flexibility.

2. Explain the different types of rigging gear used and their function?

Types of rigging gear include:

- Wire Rope and Slings: Used for lifting and supporting loads, available in various diameters and constructions.

- Shackles: Connect wire ropes and other rigging components, provide secure and load-bearing connections.

- Hooks: Attach to loads, come in various sizes and designs for different lifting requirements.

- Crosby Clamps: Used to secure wire ropes and slings to prevent slippage and ensure load stability.

3. How do you inspect and maintain rigging equipment?

Inspection and Maintenance Processes:

- Daily Inspections: Visual checks for damage, wear, and proper functionality.

- Regular Inspections: Detailed examinations to identify any defects or issues that may require repairs.

- Maintenance: Lubrication, cleaning, and replacement of worn components to ensure optimal performance and safety.

- Record Keeping: Maintaining detailed logs of inspections and maintenance activities for traceability and documentation.

4. Explain the principles of load balancing and how it is achieved in rigging operations?

- Load Balancing Principles: Distributing the weight of the load evenly across multiple rigging points.

- Achieving Load Balancing: Using rigging equipment with appropriate capacities, adjusting sling angles, and utilizing multiple hoists or cranes.

- Importance: Ensures stability, prevents overloading, and reduces the risk of equipment failure.

5. Describe the safety precautions that must be taken when operating rigging equipment?

- Training and Certification: Riggers must be properly trained and certified to operate equipment.

- Personal Protective Equipment: Wearing appropriate PPE, including hard hats, safety glasses, and gloves.

- Hazard Assessment: Identifying potential hazards and taking measures to mitigate risks.

- Inspection and Maintenance: Ensuring that equipment is regularly inspected and maintained.

- Communication: Establishing clear communication protocols between team members.

6. Explain the role of hand signals in rigging operations and how they are used?

- Standardized Signals: Establish a set of hand signals for clear communication.

- Lifting Procedures: Signals for hoisting, lowering, and stopping operations.

- Load Control: Signals for adjusting load position, centering, and balancing.

- Crane Operations: Signals for crane movement, boom positioning, and load handling.

- Emergency Situations: Signals for indicating danger, evacuating personnel, and stopping operations.

7. Describe the different methods used to secure loads during rigging operations?

- Hitching: Using ropes, slings, and other rigging gear to create secure connections between loads and lifting equipment.

- Blocking: Using wooden or composite blocks to support and stabilize loads during lifting and transportation.

- Crating: Enclosing loads within custom-built crates to provide protection and stability.

- Strapping: Using straps or banding to secure items to pallets or skids for easier handling.

8. Explain the importance of planning and coordination in rigging operations?

- Site Assessment: Evaluating the work area, load characteristics, and potential hazards.

- Equipment Selection: Choosing the appropriate hoists, cranes, and rigging gear for the job.

- Team Coordination: Establishing clear roles, responsibilities, and communication protocols.

- Load Analysis: Calculating load weights, distribution, and rigging requirements to ensure safety.

- Emergency Procedures: Developing plans to address potential incidents and ensure safety of personnel.

9. Describe the challenges faced in rigging operations and how they are overcome?

- Confined Spaces: Using smaller equipment and specialized techniques to maneuver in limited areas.

- Heavy Loads: Employing multiple hoists, cranes, and rigging systems to handle excessive weights.

- Environmental Factors: Adapting rigging methods to extreme weather conditions, wind loads, and temperature fluctuations.

- Structural Limitations: Assessing building structures to ensure they can withstand the forces of rigging operations.

10. Explain the importance of continuous learning and development for rigging professionals?

- Industry Regulations: Staying up-to-date with evolving industry standards and regulations.

- Equipment and Technology: Familiarizing with new equipment and technologies to improve efficiency and safety.

- Best Practices: Sharing and learning best practices from industry experts and experienced riggers.

- Continuous Education: Attending training courses, workshops, and conferences to enhance knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Building Rigger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Building Rigger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Building Riggers play a critical role in the construction industry, ensuring the proper setup and maintenance of equipment and structures at construction sites. Their responsibilities encompass a wide range of tasks, from erecting and dismantling scaffolding and towers to rigging hoists and cranes.

1. Scaffolding and Tower Erection and Dismantling

Building Riggers are responsible for assembling and taking down scaffolding and towers, which serve as vital access platforms for workers at various heights. They must ensure that these structures comply with safety regulations and are stable and secure.

- Assemble and disassemble scaffolding and towers according to blueprints and safety guidelines.

- Inspect scaffolding and towers regularly to ensure their structural integrity and compliance with standards.

2. Hoist and Crane Rigging

Riggers are responsible for rigging hoists and cranes, ensuring that these heavy machinery are properly attached to loads and operated safely. They must have a deep understanding of rigging techniques and equipment.

- Rig hoists and cranes to lift and lower materials and equipment.

- Inspect and maintain rigging equipment to ensure its functionality and safety.

3. Equipment Installation and Maintenance

Building Riggers are also responsible for installing and maintaining equipment on construction sites. This may include installing generators, pumps, and other machinery essential for the project’s progress.

- Install and maintain equipment on construction sites, such as generators, pumps, and compressors.

- Troubleshoot and repair equipment malfunctions promptly to minimize downtime.

4. Safety and Compliance

Safety is paramount for Building Riggers. They must adhere to strict safety protocols and ensure that all equipment and operations meet regulatory requirements. They also need to be aware of potential hazards and take appropriate precautions.

- Follow all safety regulations and procedures related to rigging operations.

- Identify and mitigate potential hazards to ensure a safe working environment.

Interview Tips

Preparing for a Building Rigger interview requires a combination of researching the industry and practicing your answers. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take the time to research the construction company and the industry as a whole. This will give you a good understanding of the company’s values, projects, and the current industry trends.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest developments.

2. Practice Your Answers

Take some time to prepare your answers to common interview questions, especially those related to your rigging experience, safety practices, and problem-solving abilities. Practicing will help you deliver clear and concise responses.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your experience.

- Ask a friend or family member to conduct a mock interview to get feedback and improve your presentation.

3. Highlight Your Skills and Experience

Make sure to highlight your relevant skills and experience that align with the job requirements. Emphasize your expertise in scaffolding and tower erection, hoist and crane rigging, and equipment installation and maintenance.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Be prepared to discuss your knowledge of safety regulations and best practices in the industry.

4. Be Professional and Enthusiastic

Throughout the interview, maintain a professional demeanor and show genuine enthusiasm for the role. Building Riggers play a vital role in ensuring the safety and efficiency of construction projects, and your passion for the industry will be evident to the interviewer.

- Dress appropriately and arrive on time for the interview.

- Make eye contact, speak clearly, and be respectful of the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Building Rigger interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.