Feeling lost in a sea of interview questions? Landed that dream interview for Pouring Crane Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pouring Crane Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

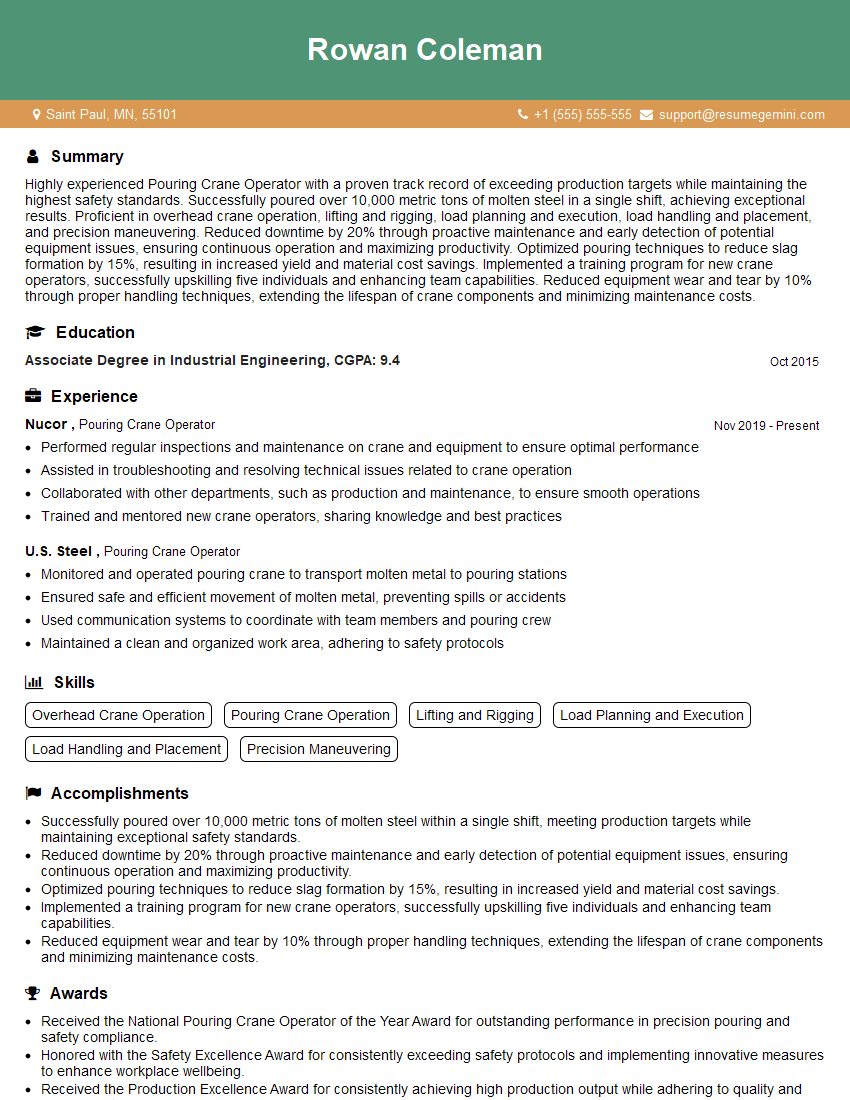

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pouring Crane Operator

1. How do you ensure the safe operation of the pouring crane?

* Conduct regular inspections of the crane and its components. * Follow established safety procedures and guidelines. * Maintain clear communication with other operators and ground personnel. * Use proper lifting techniques and avoid overloading the crane.

2. Describe the different types of pours you have experience with?

Bottom pours

- Involves pouring molten metal into a mold from below.

- Used for large and complex castings.

Top pours

- Pouring molten metal into a mold from above.

- Suitable for smaller and less intricate castings.

Continuous pours

- Maintaining a steady flow of molten metal into a mold over an extended period.

- Used in high-volume production environments.

3. What are the critical factors to consider when planning a pour?

* Type and volume of molten metal * Mold design and capacity * Crane capacity and reach * Safety procedures and potential hazards * Coordination with other personnel

4. How do you handle emergencies such as a crane malfunction or a spill?

* Assess the situation and prioritize safety. * Follow established emergency procedures. * Communicate with other operators and personnel. * Evacuate the area if necessary. * Report the incident and cooperate with the investigation.

5. What troubleshooting steps do you take when there is a problem with the pouring crane?

* Identify the source of the problem. * Check fluid levels, electrical connections, and mechanical components. * Reset or adjust settings as needed. * Request assistance from maintenance or technical support if necessary.

6. How do you ensure precision and accuracy when pouring?

* Use calibrated instruments and equipment. * Maintain a steady and controlled pour rate. * Follow established pouring techniques. * Coordinate with other operators and ground personnel.

7. What techniques do you use to minimize metal loss during a pour?

* Use preheating equipment to reduce shrinkage. * Avoid splashing and overpouring. * Use pouring gates and funnels to direct the flow. * Monitor the metal level in the mold.

8. Describe the importance of teamwork and communication in pouring crane operations.

* Clear communication ensures coordination and safety. * Teamwork allows for efficient and timely pours. * Collaboration helps identify and resolve potential issues. * Established signals and procedures enhance safety and efficiency.

9. How do you stay up to date on the latest industry best practices and safety regulations?

* Attend industry conferences and workshops. * Read trade publications and technical journals. * Participate in online training programs. * Consult with experts and mentors.

10. What are your strengths and weaknesses as a Pouring Crane Operator?

Strengths: * Highly skilled and experienced in all aspects of pouring crane operations. * Excellent problem-solving and decision-making abilities. * Strong attention to detail and safety. * Proven ability to work effectively in a team environment. Weaknesses: * Limited experience with certain types of pouring equipment. * Sometimes work slowly, especially when pouring complex shapes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pouring Crane Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pouring Crane Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pouring Crane Operator is responsible for operating a pouring crane to transport and pour molten metal into molds.

1. Equipment Operation

The operator must be able to safely and efficiently operate the pouring crane, including controlling the hoist, trolley, and bridge motions.

- Operate the pouring crane to transport molten metal from the furnace to the mold.

- Control the pouring rate and ensure that the molten metal is poured accurately into the mold.

2. Safety

The operator must follow all safety procedures and regulations, including wearing appropriate personal protective equipment.

- Follow all safety procedures and regulations, including wearing appropriate personal protective equipment.

- Inspect the pouring crane and equipment regularly to ensure that it is in good working order.

3. Troubleshooting

The operator must be able to troubleshoot and resolve minor mechanical problems with the pouring crane.

- Troubleshoot and resolve minor mechanical problems with the pouring crane.

- Report any major problems to the supervisor or maintenance personnel.

4. Communication

The operator must be able to communicate effectively with other members of the team, including the furnace operator and the molders.

- Communicate effectively with other members of the team, including the furnace operator and the molders.

- Follow instructions from the supervisor and other authorized personnel.

Interview Tips

Preparing for a job interview can be daunting, but with the right tips and preparation, you can increase your chances of success. Here are some tips to help you ace your interview for a Pouring Crane Operator position:

1. Research the Company and Position

Take the time to learn about the company you are interviewing with and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and tailor your answers accordingly.

- Visit the company’s website and social media pages to learn about their history, mission, and products or services.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

2. Practice Your Answers

Once you have a good understanding of the company and position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Brainstorm a list of potential questions that the interviewer may ask.

- Prepare thoughtful and concise answers that highlight your skills and experience.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the industry and position you are applying for.

- Choose clothing that is comfortable and allows you to move freely.

- Avoid wearing clothing that is too revealing or distracting.

4. Be Punctual

Punctuality is a sign of respect, so make sure you arrive for your interview on time. If you are running late, be sure to call or email the interviewer to let them know.

- Plan your route ahead of time and leave yourself plenty of time to get to the interview location.

- If you are running late, call or email the interviewer as soon as possible to let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pouring Crane Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!