Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Break Down Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

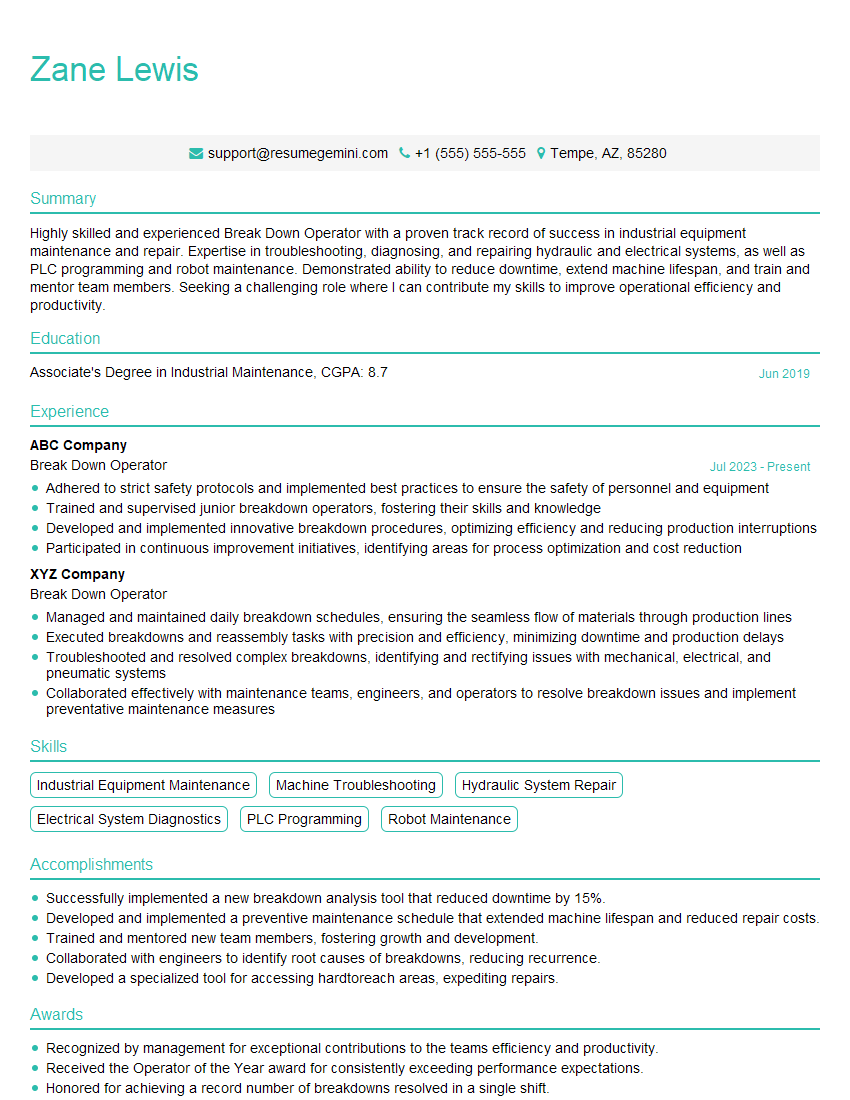

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Break Down Operator

1. Describe the key responsibilities involved in your role as a Breakdown Operator?

- Identifying and diagnosing breakdowns in machinery and equipment.

- Following established maintenance procedures to repair or replace faulty components.

- Performing preventive maintenance tasks to minimize the risk of breakdowns.

- Documenting maintenance activities and reporting any issues to superiors.

- Ensuring that machinery and equipment is operating safely and efficiently.

2. Explain the importance of adhering to established maintenance procedures?

Benefits of Adhering to Procedures

- Ensures consistent and reliable maintenance practices.

- Minimizes the risk of errors and accidents.

- Improves equipment longevity and performance.

- Facilitates efficient troubleshooting and repair.

Consequences of Ignoring Procedures

- Increased downtime and production losses.

- Safety hazards and potential injuries.

- Damage to equipment and costly repairs.

- Non-compliance with industry regulations.

3. How do you prioritize repairs when multiple breakdowns occur simultaneously?

- Assess the severity of each breakdown and its impact on production.

- Identify the critical equipment that requires immediate attention.

- Consider the availability of spare parts and personnel.

- Prioritize repairs based on their urgency and potential consequences.

- Communicate the repair plan to relevant stakeholders.

4. Describe your experience in using diagnostic tools and techniques to troubleshoot equipment issues?

- Multimeters for electrical testing.

- Pressure gauges for hydraulic systems.

- Diagnostic software for electronic equipment.

- Vibration analyzers to identify mechanical imbalances.

- Following manufacturer’s guidelines and technical manuals.

5. How do you stay updated with the latest maintenance techniques and industry best practices?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Consulting with equipment manufacturers and vendors.

- Participating in online forums and discussion groups.

- Seeking professional development opportunities.

6. Explain the role of preventive maintenance in reducing the risk of breakdowns?

- Regular inspections and condition monitoring.

- Scheduled lubrication and fluid changes.

- Tightening of bolts and connections.

- Calibration of sensors and instruments.

- Early detection of potential issues and timely repairs.

7. How do you ensure the safety of yourself and others during maintenance operations?

- Following proper lockout/tagout procedures.

- Wearing appropriate personal protective equipment.

- Inspecting equipment for potential hazards before starting work.

- Using safe work practices and tools.

- Maintaining a clean and organized work area.

8. Describe your experience in working with cross-functional teams to resolve complex maintenance issues?

Collaborative Problem-Solving

- Communicating effectively with engineers, electricians, and other skilled trades.

- Sharing technical knowledge and expertise.

- Combining different perspectives to develop innovative solutions.

Case Study

- Example of a successful collaboration that resolved a major equipment breakdown.

- Highlight your role and contributions.

- Explain how the team effort led to an efficient and effective outcome.

9. How do you manage your workload and prioritize your tasks effectively?

- Using a work order system or scheduling software.

- Setting clear priorities and deadlines.

- Delegating tasks to other team members when appropriate.

- Communicating regularly with supervisors to keep them informed of progress.

- Seeking support when needed to avoid burnout.

10. Describe your understanding of the role of technology in modern maintenance practices?

- Computerized maintenance management systems (CMMS).

- Predictive maintenance and condition monitoring.

- Remote diagnostics and troubleshooting.

- Automated data collection and analysis.

- Benefits of technology: increased efficiency, reduced downtime, improved equipment performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Break Down Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Break Down Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Break Down Operator is responsible for operating and maintaining machines and equipment in industrial settings. Their primary tasks involve troubleshooting, repairing, and replacing malfunctioning components to ensure smooth operations and prevent costly downtime.

1. Troubleshooting and Repair

Break Down Operators are tasked with identifying and resolving issues with machines and equipment. This involves diagnosing problems, replacing faulty parts, and performing necessary repairs.

- Utilize diagnostic tools and technical knowledge to pinpoint the root cause of malfunctions.

- Execute repairs promptly and efficiently to minimize downtime.

2. Maintenance and Inspection

Break Down Operators perform scheduled maintenance tasks and inspections to prevent breakdowns and ensure equipment longevity.

- Lubricate moving parts, clean components, and adjust settings.

- Conduct regular inspections to identify potential issues and take preventive measures.

3. Equipment Operation

Break Down Operators are responsible for operating machines and equipment safely and efficiently. They must have a thorough understanding of the equipment’s functions and controls.

- Operate machines according to established procedures and specifications.

- Monitor equipment performance and respond to alarms or warning signals.

4. Collaboration and Communication

Break Down Operators work closely with other departments, such as production and maintenance, to ensure efficient problem-solving and communication.

- Communicate effectively with colleagues to relay information about equipment issues and repairs.

- Collaborate with maintenance technicians to perform complex repairs and ensure adherence to safety protocols.

Interview Tips

Preparing for an interview as a Break Down Operator requires a combination of technical knowledge and a strong understanding of your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Role

Thoroughly research the company’s industry, products or services, and mission to demonstrate your interest and alignment with their goals. Familiarize yourself with the specific requirements of the Break Down Operator role and how your skills and experience match those needs.

- Visit the company’s website to gather information about their products or services.

- Read industry news and articles to stay informed about relevant technologies.

2. Practice Answering Common Interview Questions

Prepare for common interview questions by brainstorming potential answers in advance. Consider your experiences and accomplishments and tailor your responses to highlight your technical skills, problem-solving abilities, and commitment to safety.

- Describe a situation where you successfully diagnosed and repaired a complex equipment malfunction.

- How do you prioritize tasks and manage your time efficiently when dealing with multiple breakdowns?

3. Demonstrate Your Safety Consciousness

Safety is paramount in industrial settings. Emphasize your commitment to safety protocols and procedures throughout the interview. Share examples of how you have identified and mitigated potential safety hazards in previous roles.

- Highlight your understanding of lockout/tagout procedures.

- Describe your experience in conducting safety inspections and identifying potential risks.

4. Showcase Your Collaboration Skills

Break Down Operators often collaborate with other departments. Describe your experiences in working effectively as part of a team and communicating clearly with colleagues from diverse backgrounds.

- Provide examples of how you have resolved conflicts or disagreements.

- Share positive outcomes resulting from your collaboration with other team members.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Break Down Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!