Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Aircraft Quality Control Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Aircraft Quality Control Inspector so you can tailor your answers to impress potential employers.

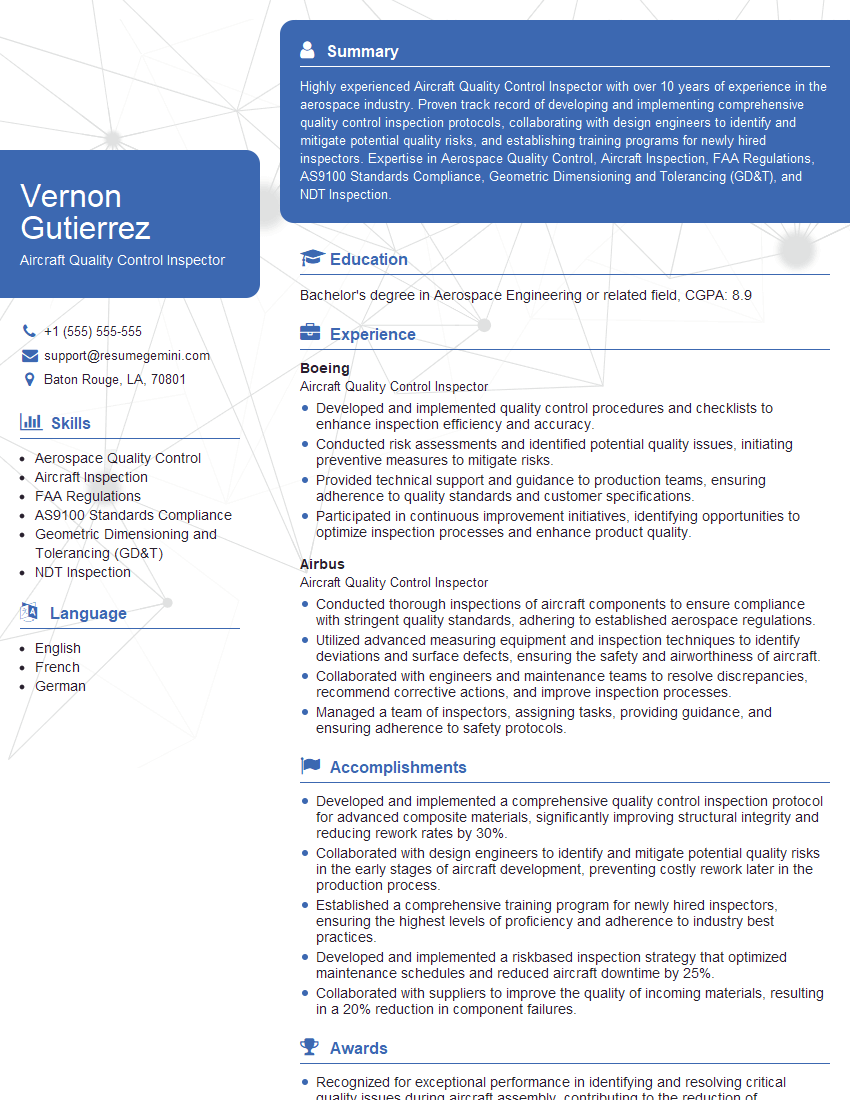

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Quality Control Inspector

1. Describe the steps involved in conducting an aircraft inspection in accordance with AS9102.

- Plan and prepare for the inspection, including gathering necessary documentation and tools.

- Examine the aircraft’s exterior and interior for any defects or damage.

- Use non-destructive testing methods to evaluate the condition of the aircraft’s components.

- Create and maintain detailed inspection reports, including photographs and measurements.

- Communicate inspection findings to the maintenance team and other stakeholders.

2. Explain the different types of aircraft inspection methods and when each is appropriate.

Visual Inspection

- Examining the aircraft’s exterior and interior for any defects or damage.

- Appropriate for detecting surface defects, such as scratches, dents, or corrosion.

Non-Destructive Testing (NDT)

- Using specialized equipment to evaluate the condition of the aircraft’s components without causing damage.

- Appropriate for detecting hidden defects, such as cracks, corrosion, or delamination.

3. What are the primary responsibilities of an Aircraft Quality Control Inspector?

- Inspecting aircraft to ensure compliance with safety and quality standards.

- Conducting non-destructive testing (NDT) to evaluate the condition of aircraft components.

- Preparing and maintaining inspection reports.

- Communicating inspection findings to the maintenance team and other stakeholders.

4. What are the qualifications and certifications required for an Aircraft Quality Control Inspector?

- Possess a high school diploma or equivalent.

- Complete formal training in aircraft inspection techniques.

- Obtain industry-recognized certifications, such as AS9102 or Nadcap.

5. How do you ensure the accuracy and reliability of your inspection results?

- Adhering to prescribed inspection procedures and standards.

- Using calibrated and certified inspection equipment.

- Maintaining a clean and organized work environment.

- Continuously updating knowledge and skills through training and industry best practices.

6. What are the most common defects or issues you encounter during aircraft inspections?

- Surface defects, such as scratches, dents, or corrosion.

- Hidden defects, such as cracks, corrosion, or delamination.

- Improper installation or assembly of components.

- Wear and tear due to normal operation or environmental factors.

7. Describe the process for reporting and documenting inspection findings.

- Creating detailed inspection reports that include photographs, measurements, and observations.

- Submitting reports to the maintenance team and other stakeholders for review and action.

- Maintaining inspection records for future reference and auditing.

8. How do you handle discrepancies or non-conformances discovered during inspections?

- Identifying and documenting the discrepancy.

- Communicating the discrepancy to the maintenance team or appropriate personnel.

- Working with the maintenance team to determine the root cause and corrective action.

9. Explain your knowledge of industry standards and regulations related to aircraft inspection.

- AS9100 (Quality Management Systems for the Aerospace Industry).

- AS9102 (Aerospace First Article Inspection Requirements).

- FAA (Federal Aviation Administration) regulations.

- EASA (European Union Aviation Safety Agency) regulations.

10. How do you prioritize inspection tasks and manage your workload effectively?

- Assessing the criticality and urgency of each inspection task.

- Prioritizing tasks based on safety, regulatory compliance, and operational needs.

- Managing workload through effective planning, scheduling, and collaboration with the maintenance team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Quality Control Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Quality Control Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Quality Control Inspectors are responsible for ensuring that aircraft and their components meet the highest quality and safety standards. Some of their key duties include:

1. Inspection and Testing

Inspecting aircraft and their components for defects, damage, or wear and tear

- Conducting visual inspections, using measuring devices, and performing non-destructive testing techniques

- Analyzing inspection data and identifying discrepancies

2. Quality Control

Monitoring and maintaining quality standards throughout the manufacturing and assembly process

- Enforcing adherence to quality control procedures and specifications

- Identifying and correcting non-conformances

3. Documentation and Reporting

Recording inspection results and maintaining accurate documentation

- Preparing inspection reports and quality control records

- Communicating inspection findings to stakeholders

4. Collaboration and Training

Working closely with engineers, production staff, and other quality control personnel

- Providing technical support and guidance

- Participating in training and development programs

Interview Tips

Interviewing for a position as an Aircraft Quality Control Inspector requires a combination of technical expertise and interpersonal skills. Here are some tips to help you prepare:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and quality standards.

- Research the latest industry trends and regulations

- Identify any unique technologies or processes used by the company

2. Highlight Your Technical Skills

Quantify your experience using specific examples of successful inspections and quality control initiatives.

- Discuss your proficiency with inspection techniques, measuring devices, and quality control software

- Emphasize your ability to identify and resolve non-conformances

3. Demonstrate Your Attention to Detail

Provide examples of your meticulous approach to inspection and testing.

- Explain your methods for ensuring accuracy and completeness

- Describe any innovative techniques you have developed to improve inspection efficiency

4. Showcase Your Communication Skills

Inspectors must be able to effectively communicate with engineers, production staff, and supervisors.

- Highlight your ability to convey technical information clearly and concisely

- Discuss your experience in preparing inspection reports and communicating findings

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aircraft Quality Control Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.