Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ship Engines Operating Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

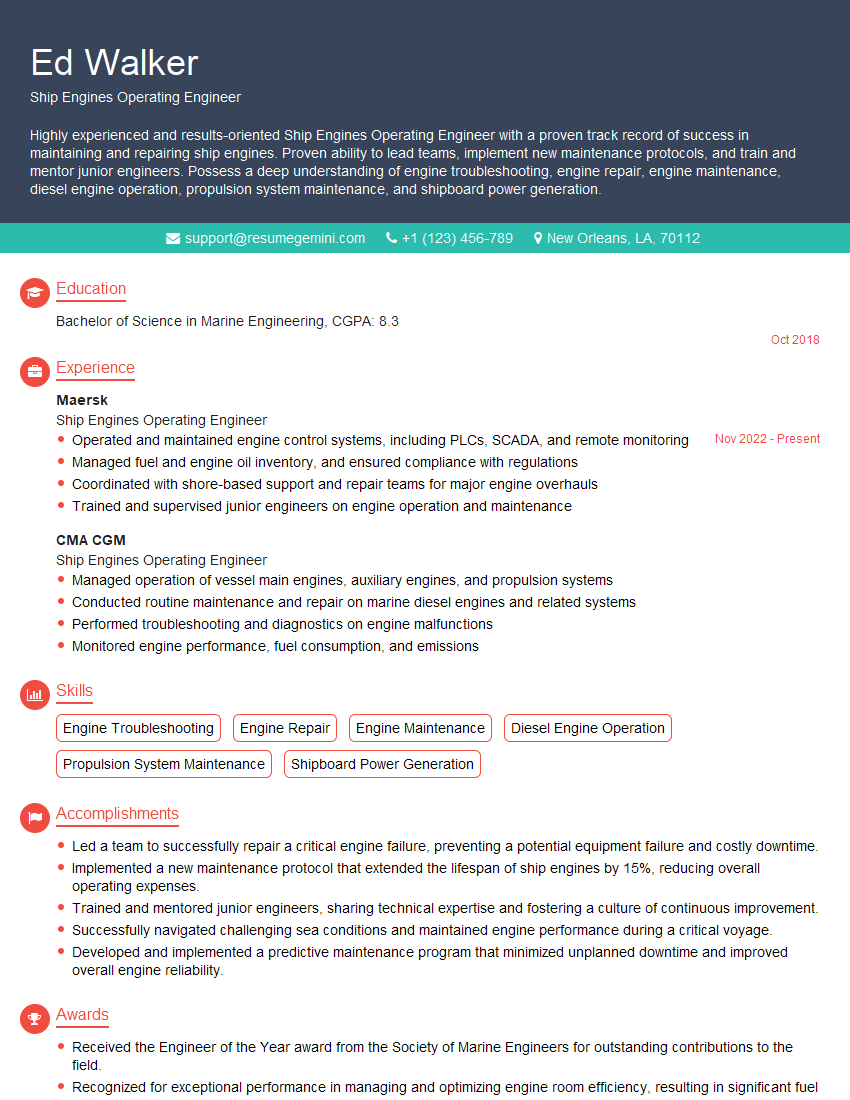

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ship Engines Operating Engineer

1. Explain the working principle of a marine diesel engine.

The marine diesel engine operates on the principle of converting chemical energy stored in the diesel fuel into mechanical energy. Here’s a detailed overview of its working principle:

- Intake Stroke: The intake valve opens, and the piston moves downward, creating a vacuum in the cylinder. Air is drawn into the cylinder through the intake valve.

- Compression Stroke: The intake valve closes, and the piston moves upward, compressing the air in the cylinder. The air temperature and pressure increase significantly.

- Injection and Ignition: Just before the piston reaches the top of the compression stroke, diesel fuel is injected into the highly compressed air through a fuel injector. The heat and pressure cause the fuel to ignite spontaneously, initiating combustion.

- Power Stroke: The combustion process produces hot, expanding gases that push the piston downward, generating power. The downward movement of the piston turns the crankshaft, converting the reciprocating motion into rotary motion.

- Exhaust Stroke: As the piston moves upward again, the exhaust valve opens. The piston pushes the combustion gases out of the cylinder through the exhaust valve. The exhaust gases are then expelled from the engine through the exhaust system.

2. Describe the different types of fuel injection systems used in marine diesel engines.

Common Rail Injection System

- Fuel is stored in a common rail at high pressure.

- Precise fuel metering and timing are achieved using electronically controlled fuel injectors.

- Provides high fuel injection pressures and flexibility in injection timing.

Unit Injector System

- Each cylinder has its own fuel injector that combines the functions of fuel injection and fuel pressure generation.

- Delivers fuel directly into the combustion chamber with high injection pressure.

- Compact and reliable design.

3. Explain the purpose and operation of a turbocharger in a marine diesel engine.

A turbocharger is a device that uses the exhaust gases from the engine to compress the air before it enters the cylinders. This increases the air density and oxygen content in the combustion chamber, leading to increased power and efficiency.

The turbocharger consists of two main components:

- Turbine: The turbine is driven by the exhaust gases, which spin the turbine blades at high speed.

- Compressor: The compressor is connected to the turbine shaft and uses the energy from the exhaust gases to compress the air.

4. Discuss the importance of maintaining proper lubrication in a marine diesel engine.

Proper lubrication is crucial for the smooth operation and longevity of a marine diesel engine. It reduces friction between moving parts, prevents wear and tear, and dissipates heat.

- Reduced Friction: Lubricating oil creates a thin film between moving parts, minimizing friction and allowing for smooth operation.

- Wear Prevention: The oil film prevents direct contact between metal surfaces, reducing wear and extending component life.

- Heat Dissipation: The lubricating oil absorbs heat generated by friction and transfers it to the cooling system, preventing overheating.

- Corrosion Protection: Lubricating oil contains additives that protect metal surfaces from corrosion and oxidation.

5. Describe the role of a scavenge air blower in a marine diesel engine.

A scavenge air blower is a device that supplies fresh air to the engine cylinders after the exhaust gases have been expelled. It helps to clear the cylinders of residual exhaust gases and ensures efficient combustion.

- Cylinder Scavenging: The blower forces fresh air into the cylinders, pushing out the exhaust gases and creating a clean environment for combustion.

- Improved Combustion: Clean air in the cylinders ensures complete and efficient combustion, leading to higher power output and fuel economy.

- Reduced Emissions: Improved combustion reduces the formation of harmful emissions such as nitrogen oxides and particulate matter.

6. Explain the principles of operation of a marine diesel generator.

A marine diesel generator converts mechanical energy from a diesel engine into electrical energy. The generator consists of two main parts:

- Diesel Engine: The diesel engine drives the generator and provides the mechanical energy.

- Alternator: The alternator converts the mechanical energy into electrical energy through electromagnetic induction.

The diesel engine operates on the same principles as other diesel engines, converting chemical energy into mechanical energy. The alternator generates electricity by rotating a magnetic rotor inside a stationary stator, inducing an electric current.

7. Discuss the safety precautions to be taken when working on a marine diesel engine.

- Lock Out/Tag Out: Isolate the engine from all power sources before performing any work.

- Personal Protective Equipment: Wear appropriate safety gear such as gloves, safety glasses, and ear protection.

- Secure Loose Objects: Remove or secure any loose tools or equipment that could fall and cause injury.

- Check for Leaks: Inspect the engine for any leaks of fuel, oil, or coolant, and rectify them before starting work.

- Ventilate the Area: Ensure adequate ventilation to prevent inhalation of harmful fumes.

8. Explain the importance of regular maintenance for marine diesel engines.

- Extended Engine Life: Regular maintenance helps identify and address minor issues before they become major problems, extending the engine’s lifespan.

- Improved Performance: Proper maintenance ensures that the engine operates at its optimal efficiency, leading to increased power output and fuel economy.

- Reduced Downtime: Regular maintenance helps prevent unexpected breakdowns and reduces the likelihood of costly repairs.

- Enhanced Safety: A well-maintained engine operates more reliably and safely, reducing the risk of accidents or injuries.

9. Describe the troubleshooting steps you would take if a marine diesel engine is not starting.

- Check Fuel Supply: Verify that there is fuel in the tank and that the fuel lines are not blocked.

- Inspect Fuel Injection System: Ensure that the fuel injectors are functioning properly and delivering fuel to the cylinders.

- Check Air Intake: Inspect the air filter and ensure that there is no restriction in the air intake system.

- Verify Electrical System: Test the battery, starter motor, and electrical connections to ensure they are functioning properly.

- Examine Compression: Perform a compression test to determine if there is sufficient compression in the cylinders.

10. Discuss the environmental regulations that apply to marine diesel engines.

Marine diesel engines must comply with various environmental regulations to minimize their impact on the environment. These regulations include:

- Emission Standards: Regulations such as MARPOL Annex VI limit the emission of pollutants such as nitrogen oxides, sulfur oxides, and particulate matter.

- Fuel Quality: Regulations require the use of low-sulfur fuels to reduce sulfur oxide emissions.

- Ballast Water Management: Regulations aim to prevent the spread of invasive species by treating or exchanging ballast water.

- Noise Pollution: Regulations limit the noise produced by marine diesel engines to protect marine life and coastal communities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ship Engines Operating Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ship Engines Operating Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Ship Engines Operating Engineer is responsible for the operation, maintenance, and repair of marine engines and propulsion systems. They ensure that the engines are operating efficiently and safely, and that the ship is able to navigate and perform its intended functions.

1. Operate Marine Engines

A Ship Engines Operating Engineer is responsible for the operation of all ship engines, including diesel engines, steam engines, and gas turbines. They must be able to start, stop, and control the engines, as well as monitor their performance and make adjustments as needed.

2. Maintain and Repair Marine Engines

A Ship Engines Operating Engineer also performs maintenance and repairs on ship engines. This includes tasks such as changing oil, filters, and spark plugs, as well as more complex repairs such as rebuilding engines or replacing damaged parts.

3. Troubleshooting and Problem-solving

A Ship Engines Operating Engineer must be able to troubleshoot and solve problems with marine engines. This may involve diagnosing problems, determining the cause, and taking corrective action.

4. Safety

A Ship Engines Operating Engineer is responsible for the safety of themselves and others around them. They must adhere to all safety regulations and procedures, and take all necessary precautions to prevent accidents or injuries.

Interview Tips

Preparing for an interview for a Ship Engines Operating Engineer position can be daunting, but there are steps you can take to increase your chances of success. Here are a few tips:

1. Research the company and the position

Before you go to the interview, make sure you do your research on the company and the specific position. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find this information on the company’s website, in industry publications, or by talking to people who work there.

2. Prepare your answers to common interview questions

There are certain questions that are commonly asked in interviews for Ship Engines Operating Engineer positions. These questions may include:

- Tell me about your experience operating and maintaining marine engines.

- What are some of the challenges you have faced in your previous roles?

- How do you stay up-to-date on the latest advancements in marine engine technology?

Take some time to think about how you would answer these questions before you go to the interview. This will help you feel more confident and prepared during the interview.

3. Highlight your skills and experience

Make sure to highlight your skills and experience in your resume and cover letter. Be specific about the types of engines you have operated and maintained, and the specific tasks you have performed. You should also mention any certifications or training you have received.

4. Be prepared to talk about your safety record

Safety is a top priority for Ship Engines Operating Engineers. In your interview, be prepared to talk about your safety record and how you have prevented accidents or injuries in the past.

5. Practice your interview skills

The more you practice, the more confident you will be during your interview. You can practice by yourself or with a friend or family member. Make sure you practice answering the common interview questions, as well as questions specific to the position you are applying for.

6. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing a suit or business casual attire. You should also be well-groomed and have clean hands and nails.

7. Be on time

It is important to be on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

8. Be positive and enthusiastic

A positive and enthusiastic attitude can go a long way in an interview. Make sure you are polite and respectful to the interviewer, and be sure to highlight your passion for the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Ship Engines Operating Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.