Are you gearing up for a career in Turntable Engineer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Turntable Engineer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

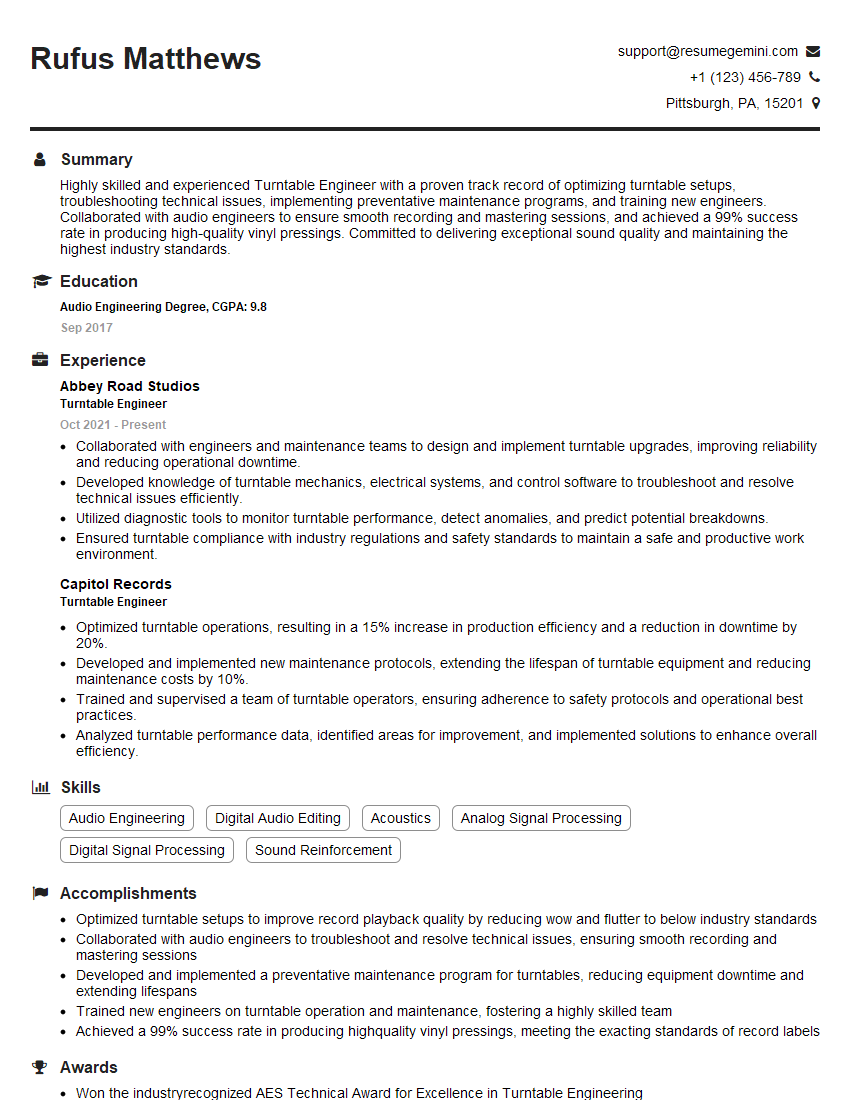

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turntable Engineer

1. What are the essential components of a turntable system and explain how they work together?

- Platter: The platter is the rotating part of the turntable that holds the record in place.

- Motor: The motor drives the platter and provides the power to rotate the record.

- Tonearm: The tonearm holds the cartridge and stylus that reads the information from the record’s grooves.

- Cartridge: The cartridge converts the mechanical vibrations from the stylus into electrical signals.

- Stylus: The stylus is the needle-shaped tip of the cartridge that makes physical contact with the record’s grooves and reads the music encoded within them.

2. Describe the different types of turntable drive systems and their advantages and disadvantages.

Belt drive systems

- Pros: Reduced noise and vibration, good isolation from motor vibrations, consistent speed.

- Cons: Can be more expensive than other drive systems, may require more maintenance.

Direct drive systems

- Pros: Powerful, high torque, good speed accuracy, fast start-up time.

- Cons: Can be noisy due to motor vibrations, more prone to wear and tear.

Idler drive systems

- Pros: Low noise, good speed accuracy, can be used with both AC and DC motors.

- Cons: Can be more complex to maintain, may require more frequent lubrication.

3. Explain the concepts of alignment, azimuth, and VTA, and how they affect the sound quality of a turntable.

- Alignment: Refers to the correct alignment of the cartridge and stylus with the record’s grooves. Proper alignment ensures optimal tracking and minimizes distortion.

- Azimuth: Refers to the angle of the cartridge in relation to the record’s surface. Correct azimuth ensures that the stylus makes proper contact with the groove walls and reduces sibilance.

- VTA (Vertical Tracking Angle): Refers to the angle of the tonearm in relation to the record’s surface. Proper VTA ensures that the stylus tracks the record’s grooves at the correct angle, reducing mistracking and wear on the record and stylus.

4. Describe the different types of turntable mats and their effects on sound quality.

- Rubber mats: Provide good isolation from vibrations and can reduce static electricity.

- Felt mats: Have a warmer sound and can absorb some vibrations, but may increase static electricity.

- Cork mats: Offer a combination of isolation and warmth, with good shock absorption properties.

- Leather mats: Provide a natural, warm sound and can be very durable.

5. Explain the importance of regular maintenance for a turntable and describe the key steps involved in maintaining a turntable.

- Cleaning: Regular cleaning of the turntable platter, stylus, and tonearm is essential to remove dust and debris that can affect performance.

- Lubrication: Turntable bearings and other moving parts may require lubrication to ensure smooth operation and reduce wear.

- Belt replacement: Turntables with belt drive systems may require periodic belt replacement as the belt can stretch or deteriorate over time.

- Suspension adjustment: Turntables with suspended sub-chassis may require periodic adjustment to ensure optimal isolation from vibrations.

6. How would you troubleshoot a turntable that is not rotating or has uneven speed?

- Check the power supply and connections to ensure that the turntable is receiving power.

- Inspect the drive belt or idler wheel for damage or wear and replace if necessary.

- Check the motor for any signs of damage or blockage and clean or repair as needed.

- Check the speed control circuit and adjust or replace components as necessary to ensure proper speed regulation.

7. Describe the different types of phono cartridges and explain how they affect the sound quality of a turntable.

- Moving magnet (MM) cartridges: Use a magnet attached to the stylus to generate an electrical signal, and are generally more affordable.

- Moving coil (MC) cartridges: Use coils attached to the stylus to generate an electrical signal, and are typically more expensive but offer higher sound quality.

- High-output moving coil (HOMC) cartridges: A hybrid design that combines features of both MM and MC cartridges, providing a higher output voltage than MC cartridges while retaining some of their sonic advantages.

8. Explain the concept of phono equalization and how it is applied to turntable systems.

- Phono equalization is a process of adjusting the frequency response of a turntable’s output signal to compensate for the inherent roll-off of low frequencies and boost of high frequencies that occurs when a record is cut.

- This equalization is typically applied using a phono preamplifier, which can be built into the turntable or used as a separate component.

9. Describe the different types of turntable isolation systems and how they reduce unwanted vibrations.

- Spring-based isolation: Uses springs to support the turntable and isolate it from external vibrations.

- Air-based isolation: Uses air pockets or bladders to support the turntable and provide damping against vibrations.

- Material-based isolation: Uses materials such as rubber or cork to absorb and dampen vibrations.

10. Explain the importance of proper grounding in a turntable system and how to ensure proper grounding.

- Proper grounding is essential to reduce noise and interference in a turntable system.

- The turntable, tonearm, and other components should be properly grounded to a common ground point, typically the amplifier or preamplifier.

- Ground wires should be of high quality and properly connected to prevent ground loops or hum.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turntable Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turntable Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Turntable Engineers are responsible for the operation and maintenance of turntables, which are used to rotate vehicles on tracks. They ensure that the turntables are operating safely and efficiently, and that all safety regulations are adhered to.

1. Operation of Turntables

Turntable Engineers are responsible for the day-to-day operation of turntables. This includes:

- Starting and stopping the turntable

- Controlling the speed and direction of rotation

- Monitoring the turntable for any signs of damage or malfunction

2. Maintenance of Turntables

Turntable Engineers are also responsible for the maintenance of turntables. This includes:

- Inspecting the turntable regularly for any signs of wear or damage

- Lubricating the turntable and its components

- Replacing any worn or damaged parts

3. Safety Procedures

Turntable Engineers must be familiar with all safety procedures related to the operation and maintenance of turntables. This includes:

- Emergency stop procedures

- Lockout/tagout procedures

- Personal protective equipment (PPE) requirements

4. Troubleshooting

Turntable Engineers must be able to troubleshoot any problems that may occur with the turntable. This includes:

- Identifying the source of the problem

- Determining the best course of action to resolve the problem

- Making repairs or adjustments as necessary

Interview Tips

Preparing for an interview for a Turntable Engineer position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you prepare:

1. Research the Company and Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the position.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work for the company

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare a brief introduction of yourself

- Highlight your skills and experience that are relevant to the position

- Explain why you are interested in the company and the position

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience in the field of turntable engineering. Be prepared to talk about your experience in detail, including your successes and failures.

- Quantify your accomplishments with specific examples

- Highlight your problem-solving skills

- Be prepared to discuss your experience with safety procedures

4. Ask Questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position. It is also a good way to show the interviewer that you are interested in the position and that you have done your research.

- Ask about the company’s culture

- Ask about the day-to-day responsibilities of the position

- Ask about the company’s future plans

Next Step:

Now that you’re armed with the knowledge of Turntable Engineer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Turntable Engineer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini