Are you a seasoned Factory Manager seeking a new career path? Discover our professionally built Factory Manager Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

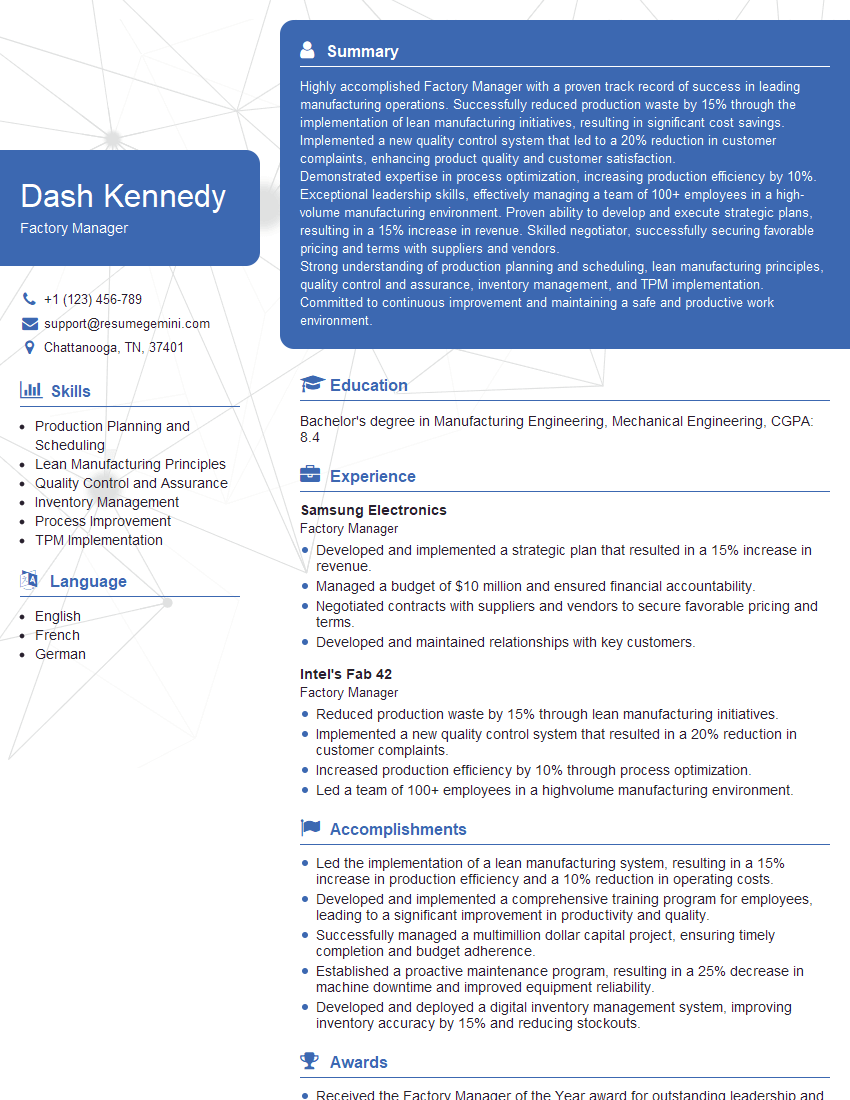

Dash Kennedy

Factory Manager

Summary

Highly accomplished Factory Manager with a proven track record of success in leading manufacturing operations. Successfully reduced production waste by 15% through the implementation of lean manufacturing initiatives, resulting in significant cost savings. Implemented a new quality control system that led to a 20% reduction in customer complaints, enhancing product quality and customer satisfaction.

Demonstrated expertise in process optimization, increasing production efficiency by 10%. Exceptional leadership skills, effectively managing a team of 100+ employees in a high-volume manufacturing environment. Proven ability to develop and execute strategic plans, resulting in a 15% increase in revenue. Skilled negotiator, successfully securing favorable pricing and terms with suppliers and vendors.

Strong understanding of production planning and scheduling, lean manufacturing principles, quality control and assurance, inventory management, and TPM implementation. Committed to continuous improvement and maintaining a safe and productive work environment.

Education

Bachelor’s degree in Manufacturing Engineering, Mechanical Engineering

April 2018

Skills

- Production Planning and Scheduling

- Lean Manufacturing Principles

- Quality Control and Assurance

- Inventory Management

- Process Improvement

- TPM Implementation

Work Experience

Factory Manager

- Developed and implemented a strategic plan that resulted in a 15% increase in revenue.

- Managed a budget of $10 million and ensured financial accountability.

- Negotiated contracts with suppliers and vendors to secure favorable pricing and terms.

- Developed and maintained relationships with key customers.

Factory Manager

- Reduced production waste by 15% through lean manufacturing initiatives.

- Implemented a new quality control system that resulted in a 20% reduction in customer complaints.

- Increased production efficiency by 10% through process optimization.

- Led a team of 100+ employees in a highvolume manufacturing environment.

Accomplishments

- Led the implementation of a lean manufacturing system, resulting in a 15% increase in production efficiency and a 10% reduction in operating costs.

- Developed and implemented a comprehensive training program for employees, leading to a significant improvement in productivity and quality.

- Successfully managed a multimillion dollar capital project, ensuring timely completion and budget adherence.

- Established a proactive maintenance program, resulting in a 25% decrease in machine downtime and improved equipment reliability.

- Developed and deployed a digital inventory management system, improving inventory accuracy by 15% and reducing stockouts.

Awards

- Received the Factory Manager of the Year award for outstanding leadership and operational excellence.

- Recognized for exceptional safety performance, achieving a recordlow number of workplace accidents and incidents.

- Received the Innovation Award for developing a new manufacturing process that reduced production time by 20%.

- Recognized for outstanding customer service, consistently exceeding customer expectations and building strong relationships.

Certificates

- Certified Production Manager (CPM)

- Certified Quality Engineer (CQE)

- Six Sigma Black Belt

- OSHA 30-Hour General Industry Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Factory Manager

1. Quantify your accomplishments:

Use specific numbers and metrics to demonstrate the impact of your work. For example, instead of saying “Reduced production waste,” say “Reduced production waste by 15% through the implementation of lean manufacturing initiatives.”

2. Highlight your leadership skills:

Factory managers are responsible for leading and motivating a team of employees. Emphasize your ability to build and maintain a positive work environment, resolve conflicts, and inspire your team to achieve goals.

3. Showcase your technical knowledge:

Factory managers need to have a strong understanding of manufacturing processes, quality control, and inventory management. Highlight your expertise in these areas and explain how you have used your knowledge to improve factory operations.

4. Tailor your resume to each job you apply for:

Take the time to read the job description carefully and identify the skills and experience that the employer is looking for. Make sure to highlight these skills and experience in your resume.

5. Proofread your resume carefully:

A well-written resume is free of errors. Proofread your resume carefully before submitting it to potential employers.

Essential Experience Highlights for a Strong Factory Manager Resume

- Plan, direct, and coordinate all aspects of factory operations, including production, quality control, and maintenance.

- Develop and implement strategic plans to improve productivity, efficiency, and profitability.

- Manage a team of employees and ensure their training, development, and motivation.

- Oversee the implementation of quality control systems and ensure compliance with industry standards.

- Monitor production processes and identify areas for improvement.

- Work with suppliers and vendors to ensure the timely delivery of materials and equipment.

- Prepare and present reports on factory performance to senior management.

Frequently Asked Questions (FAQ’s) For Factory Manager

What are the key responsibilities of a Factory Manager?

Factory Managers are responsible for the overall operation of a factory, including planning, directing, and coordinating all aspects of production, quality control, and maintenance. They also manage a team of employees, oversee the implementation of quality control systems, and work with suppliers and vendors.

What are the qualifications for a Factory Manager?

Factory Managers typically have a bachelor’s degree in Manufacturing Engineering, Mechanical Engineering, or a related field. They also have several years of experience in manufacturing operations management.

What are the skills required to be a Factory Manager?

Factory Managers need to have strong leadership skills, as well as a deep understanding of manufacturing processes, quality control, and inventory management. They also need to be able to effectively communicate with employees, suppliers, and customers.

What is the job outlook for Factory Managers?

The job outlook for Factory Managers is expected to be good over the next few years. As the manufacturing sector continues to grow, there will be a need for qualified Factory Managers to oversee operations.

What is the average salary for a Factory Manager?

The average salary for a Factory Manager is around $100,000 per year. However, salaries can vary depending on experience, location, and company size.

What are the benefits of working as a Factory Manager?

Factory Managers enjoy a number of benefits, including a competitive salary, health insurance, and retirement benefits. They also have the opportunity to work in a challenging and rewarding environment.

What are the challenges of working as a Factory Manager?

Factory Managers face a number of challenges, including managing a large team of employees, overseeing complex manufacturing processes, and meeting production goals. They also need to be able to adapt to changing market conditions and technological advancements.