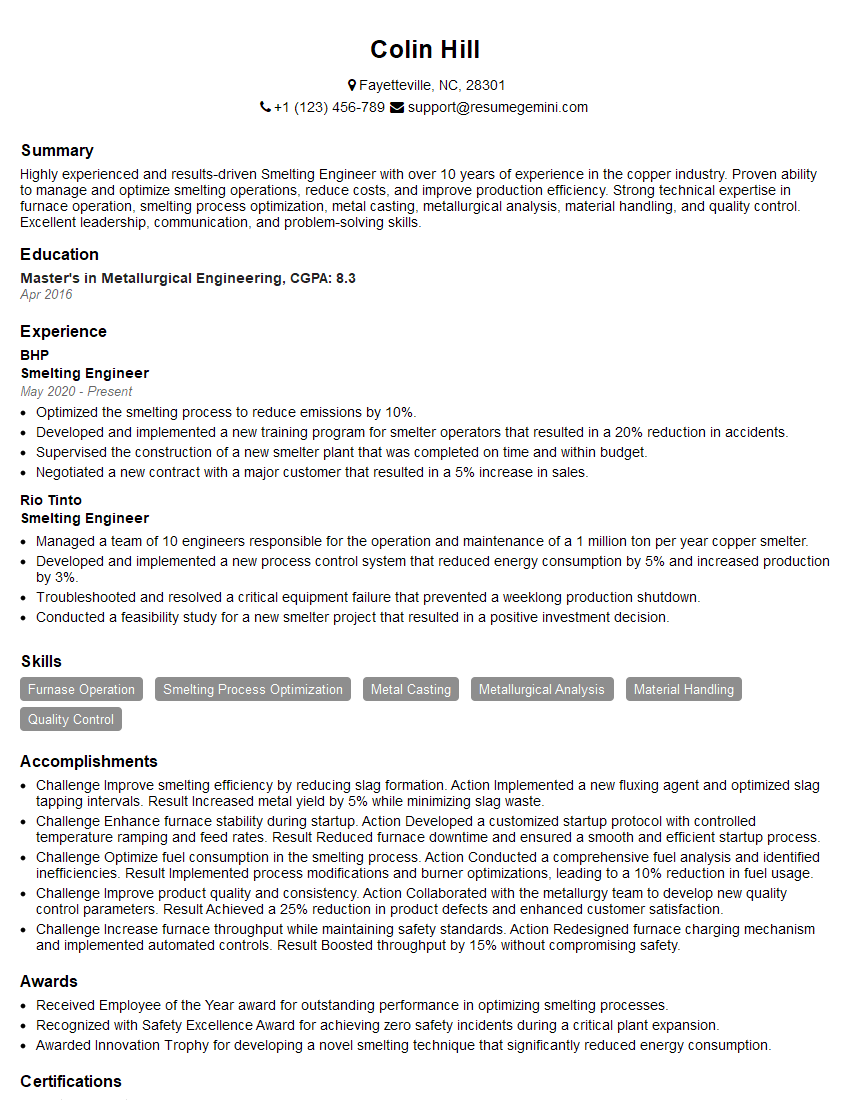

Colin Hill

Smelting Engineer

Summary

Highly experienced and results-driven Smelting Engineer with over 10 years of experience in the copper industry. Proven ability to manage and optimize smelting operations, reduce costs, and improve production efficiency. Strong technical expertise in furnace operation, smelting process optimization, metal casting, metallurgical analysis, material handling, and quality control. Excellent leadership, communication, and problem-solving skills.

Education

Master’s in Metallurgical Engineering

April 2016

Skills

- Furnase Operation

- Smelting Process Optimization

- Metal Casting

- Metallurgical Analysis

- Material Handling

- Quality Control

Work Experience

Smelting Engineer

- Optimized the smelting process to reduce emissions by 10%.

- Developed and implemented a new training program for smelter operators that resulted in a 20% reduction in accidents.

- Supervised the construction of a new smelter plant that was completed on time and within budget.

- Negotiated a new contract with a major customer that resulted in a 5% increase in sales.

Smelting Engineer

- Managed a team of 10 engineers responsible for the operation and maintenance of a 1 million ton per year copper smelter.

- Developed and implemented a new process control system that reduced energy consumption by 5% and increased production by 3%.

- Troubleshooted and resolved a critical equipment failure that prevented a weeklong production shutdown.

- Conducted a feasibility study for a new smelter project that resulted in a positive investment decision.

Accomplishments

- Challenge Improve smelting efficiency by reducing slag formation. Action Implemented a new fluxing agent and optimized slag tapping intervals. Result Increased metal yield by 5% while minimizing slag waste.

- Challenge Enhance furnace stability during startup. Action Developed a customized startup protocol with controlled temperature ramping and feed rates. Result Reduced furnace downtime and ensured a smooth and efficient startup process.

- Challenge Optimize fuel consumption in the smelting process. Action Conducted a comprehensive fuel analysis and identified inefficiencies. Result Implemented process modifications and burner optimizations, leading to a 10% reduction in fuel usage.

- Challenge Improve product quality and consistency. Action Collaborated with the metallurgy team to develop new quality control parameters. Result Achieved a 25% reduction in product defects and enhanced customer satisfaction.

- Challenge Increase furnace throughput while maintaining safety standards. Action Redesigned furnace charging mechanism and implemented automated controls. Result Boosted throughput by 15% without compromising safety.

Awards

- Received Employee of the Year award for outstanding performance in optimizing smelting processes.

- Recognized with Safety Excellence Award for achieving zero safety incidents during a critical plant expansion.

- Awarded Innovation Trophy for developing a novel smelting technique that significantly reduced energy consumption.

Certificates

- Certified Smelting Engineer (CSE)

- ASQ Certified Quality Engineer (CQE)

- OSHA Safety Training

- First Aid and CPR Certification

How To Write Resume For Smelting Engineer

- Highlight your technical expertise and quantify your accomplishments whenever possible.

- Demonstrate your leadership and management skills by describing your experience in managing teams and projects.

- Showcase your ability to improve processes and increase efficiency.

- Emphasize your problem-solving skills and ability to handle crisis situations.

Essential Experience Highlights for a Strong Smelting Engineer Resume

- Managed and led a team of 10 engineers in the operation and maintenance of a 1 million ton per year copper smelter.

- Developed and implemented a new process control system that reduced energy consumption by 5% and increased production by 3%.

- Troubleshooted and resolved a critical equipment failure that prevented a weeklong production shutdown.

- Conducted a feasibility study for a new smelter project that resulted in a positive investment decision.

- Optimized the smelting process to reduce emissions by 10%.

- Developed and implemented a new training program for smelter operators that resulted in a 20% reduction in accidents.

- Supervised the construction of a new smelter plant that was completed on time and within budget.

Frequently Asked Questions (FAQ’s) For Smelting Engineer

What is the role of a Smelting Engineer?

A Smelting Engineer is responsible for the operation and maintenance of smelting furnaces and other equipment used in the smelting process. They also develop and improve smelting processes to increase efficiency and reduce costs.

What are the qualifications required to become a Smelting Engineer?

A Smelting Engineer typically requires a Bachelor’s or Master’s degree in Metallurgical Engineering or a related field, as well as several years of experience in the smelting industry.

What are the key skills required for a Smelting Engineer?

Key skills for a Smelting Engineer include furnace operation, smelting process optimization, metal casting, metallurgical analysis, material handling, and quality control.

What are the career prospects for a Smelting Engineer?

Smelting Engineers can advance to management positions, such as Smelting Manager or Plant Manager. They can also specialize in a particular area of smelting, such as process optimization or environmental control.

What is the salary range for a Smelting Engineer?

The salary range for a Smelting Engineer can vary depending on experience, location, and company size. According to Salary.com, the average salary for a Smelting Engineer in the United States is around $90,000 per year.