Are you a seasoned Manufacturing Systems Engineer seeking a new career path? Discover our professionally built Manufacturing Systems Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

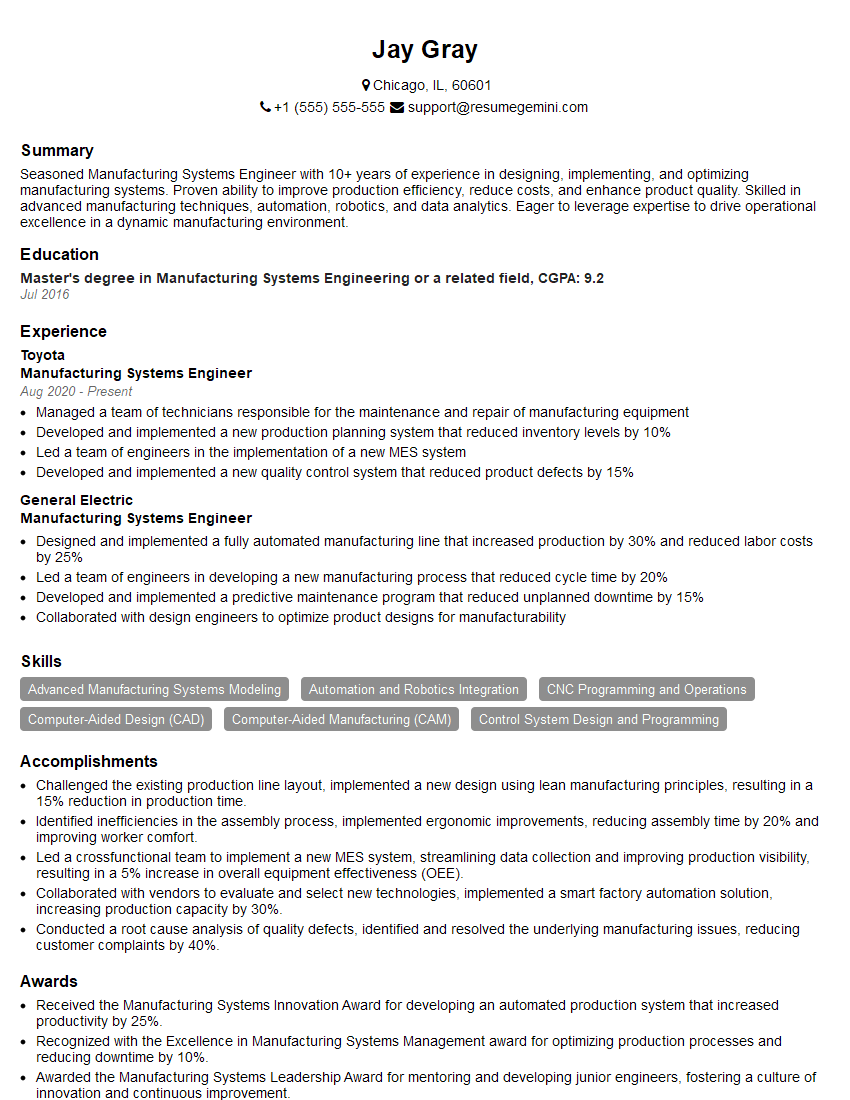

Jay Gray

Manufacturing Systems Engineer

Summary

Seasoned Manufacturing Systems Engineer with 10+ years of experience in designing, implementing, and optimizing manufacturing systems. Proven ability to improve production efficiency, reduce costs, and enhance product quality. Skilled in advanced manufacturing techniques, automation, robotics, and data analytics. Eager to leverage expertise to drive operational excellence in a dynamic manufacturing environment.

Education

Master’s degree in Manufacturing Systems Engineering or a related field

July 2016

Skills

- Advanced Manufacturing Systems Modeling

- Automation and Robotics Integration

- CNC Programming and Operations

- Computer-Aided Design (CAD)

- Computer-Aided Manufacturing (CAM)

- Control System Design and Programming

Work Experience

Manufacturing Systems Engineer

- Managed a team of technicians responsible for the maintenance and repair of manufacturing equipment

- Developed and implemented a new production planning system that reduced inventory levels by 10%

- Led a team of engineers in the implementation of a new MES system

- Developed and implemented a new quality control system that reduced product defects by 15%

Manufacturing Systems Engineer

- Designed and implemented a fully automated manufacturing line that increased production by 30% and reduced labor costs by 25%

- Led a team of engineers in developing a new manufacturing process that reduced cycle time by 20%

- Developed and implemented a predictive maintenance program that reduced unplanned downtime by 15%

- Collaborated with design engineers to optimize product designs for manufacturability

Accomplishments

- Challenged the existing production line layout, implemented a new design using lean manufacturing principles, resulting in a 15% reduction in production time.

- Identified inefficiencies in the assembly process, implemented ergonomic improvements, reducing assembly time by 20% and improving worker comfort.

- Led a crossfunctional team to implement a new MES system, streamlining data collection and improving production visibility, resulting in a 5% increase in overall equipment effectiveness (OEE).

- Collaborated with vendors to evaluate and select new technologies, implemented a smart factory automation solution, increasing production capacity by 30%.

- Conducted a root cause analysis of quality defects, identified and resolved the underlying manufacturing issues, reducing customer complaints by 40%.

Awards

- Received the Manufacturing Systems Innovation Award for developing an automated production system that increased productivity by 25%.

- Recognized with the Excellence in Manufacturing Systems Management award for optimizing production processes and reducing downtime by 10%.

- Awarded the Manufacturing Systems Leadership Award for mentoring and developing junior engineers, fostering a culture of innovation and continuous improvement.

- Received the Industry 4.0 Pioneer Award for developing and implementing a predictive maintenance program that reduced machine downtime and improved production efficiency.

Certificates

- Certified Manufacturing Engineer (CMfgE)

- Certified Lean Six Sigma Black Belt

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Quality Engineer (CQE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Manufacturing Systems Engineer

- Quantify your accomplishments with specific metrics and data whenever possible.

- Highlight your experience in implementing cutting-edge manufacturing technologies, such as automation, robotics, and data analytics.

- Showcase your ability to work effectively in a cross-functional team environment and collaborate with engineers, technicians, and operators.

- Demonstrate your understanding of lean manufacturing principles and continuous improvement methodologies.

- Use action verbs and strong keywords throughout your resume to highlight your skills and experience.

Essential Experience Highlights for a Strong Manufacturing Systems Engineer Resume

- Design and implement comprehensive manufacturing systems to optimize production processes and enhance efficiency.

- Lead cross-functional teams in developing and deploying innovative manufacturing solutions, including automation and robotics integration.

- Analyze production data, identify bottlenecks, and implement lean manufacturing principles to reduce cycle time and improve throughput.

- Collaborate with design engineers to optimize product designs for manufacturability, ensuring smooth integration into production processes.

- Establish and manage preventive maintenance programs to minimize unplanned downtime and maximize equipment uptime.

- Develop and implement robust quality control systems to ensure product quality and adherence to industry standards.

- Stay abreast of emerging manufacturing technologies and best practices to continuously improve manufacturing systems and drive productivity.

- Provide technical expertise and guidance to manufacturing teams to enhance operational efficiency and problem-solving capabilities.

- Conduct training programs for operators and maintenance personnel to ensure proper operation and maintenance of manufacturing systems.

Frequently Asked Questions (FAQ’s) For Manufacturing Systems Engineer

What is the primary role of a Manufacturing Systems Engineer?

A Manufacturing Systems Engineer designs, implements, and optimizes manufacturing systems to enhance production efficiency, reduce costs, and improve product quality.

What skills are essential for success as a Manufacturing Systems Engineer?

Essential skills include expertise in manufacturing processes, automation, robotics, data analysis, lean manufacturing principles, and project management.

What industries employ Manufacturing Systems Engineers?

Manufacturing Systems Engineers are employed in a wide range of industries, including automotive, aerospace, electronics, consumer products, and healthcare.

What is the career outlook for Manufacturing Systems Engineers?

The career outlook for Manufacturing Systems Engineers is positive due to the increasing demand for professionals with expertise in optimizing manufacturing processes and enhancing productivity.

What are the earning prospects for Manufacturing Systems Engineers?

Manufacturing Systems Engineers with experience and expertise can command competitive salaries and benefits packages.

What professional development opportunities are available for Manufacturing Systems Engineers?

Manufacturing Systems Engineers can pursue professional development through industry certifications, workshops, conferences, and advanced degree programs.

What are the key challenges faced by Manufacturing Systems Engineers?

Key challenges include integrating new technologies, optimizing production processes in a rapidly changing manufacturing landscape, and ensuring compliance with industry regulations and standards.

What are the essential qualities of a successful Manufacturing Systems Engineer?

Successful Manufacturing Systems Engineers possess strong analytical and problem-solving skills, are detail-oriented, and have a passion for continuous improvement.

How can I prepare for a career as a Manufacturing Systems Engineer?

To prepare for a career as a Manufacturing Systems Engineer, consider pursuing a degree in manufacturing engineering or a related field, gaining practical experience through internships or co-ops, and developing strong technical skills in areas such as automation, robotics, and data analysis.