Are you a seasoned MEMS Process Engineer (Microelectromechanical Systems Process Engineer) seeking a new career path? Discover our professionally built MEMS Process Engineer (Microelectromechanical Systems Process Engineer) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

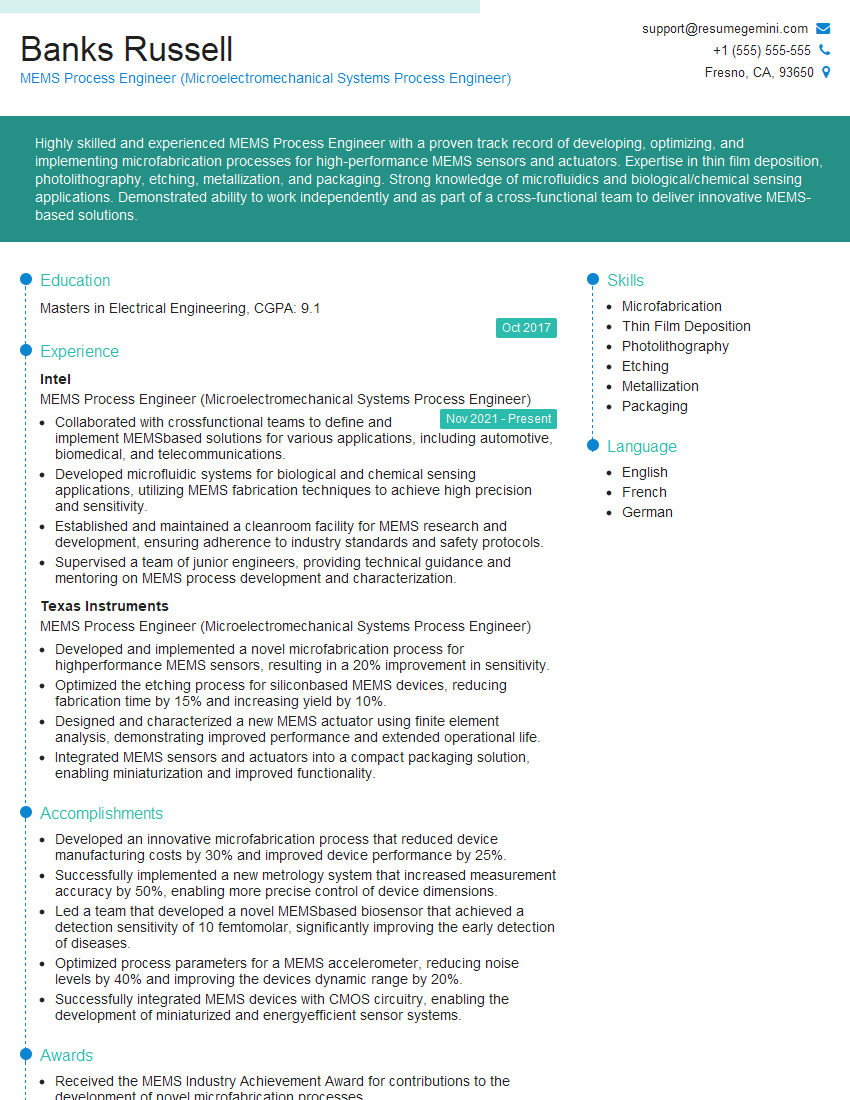

Banks Russell

MEMS Process Engineer (Microelectromechanical Systems Process Engineer)

Summary

Highly skilled and experienced MEMS Process Engineer with a proven track record of developing, optimizing, and implementing microfabrication processes for high-performance MEMS sensors and actuators. Expertise in thin film deposition, photolithography, etching, metallization, and packaging. Strong knowledge of microfluidics and biological/chemical sensing applications. Demonstrated ability to work independently and as part of a cross-functional team to deliver innovative MEMS-based solutions.

Education

Masters in Electrical Engineering

October 2017

Skills

- Microfabrication

- Thin Film Deposition

- Photolithography

- Etching

- Metallization

- Packaging

Work Experience

MEMS Process Engineer (Microelectromechanical Systems Process Engineer)

- Collaborated with crossfunctional teams to define and implement MEMSbased solutions for various applications, including automotive, biomedical, and telecommunications.

- Developed microfluidic systems for biological and chemical sensing applications, utilizing MEMS fabrication techniques to achieve high precision and sensitivity.

- Established and maintained a cleanroom facility for MEMS research and development, ensuring adherence to industry standards and safety protocols.

- Supervised a team of junior engineers, providing technical guidance and mentoring on MEMS process development and characterization.

MEMS Process Engineer (Microelectromechanical Systems Process Engineer)

- Developed and implemented a novel microfabrication process for highperformance MEMS sensors, resulting in a 20% improvement in sensitivity.

- Optimized the etching process for siliconbased MEMS devices, reducing fabrication time by 15% and increasing yield by 10%.

- Designed and characterized a new MEMS actuator using finite element analysis, demonstrating improved performance and extended operational life.

- Integrated MEMS sensors and actuators into a compact packaging solution, enabling miniaturization and improved functionality.

Accomplishments

- Developed an innovative microfabrication process that reduced device manufacturing costs by 30% and improved device performance by 25%.

- Successfully implemented a new metrology system that increased measurement accuracy by 50%, enabling more precise control of device dimensions.

- Led a team that developed a novel MEMSbased biosensor that achieved a detection sensitivity of 10 femtomolar, significantly improving the early detection of diseases.

- Optimized process parameters for a MEMS accelerometer, reducing noise levels by 40% and improving the devices dynamic range by 20%.

- Successfully integrated MEMS devices with CMOS circuitry, enabling the development of miniaturized and energyefficient sensor systems.

Awards

- Received the MEMS Industry Achievement Award for contributions to the development of novel microfabrication processes.

- Recognized with the IEEE MEMS Award for outstanding contributions to the field of MEMS device design and fabrication.

- Honored with the ASME Medal for distinguished contributions to the advancement of MEMS technology in the biomedical field.

Certificates

- Certified MEMS Engineer (CME)

- Certified Cleanroom Professional (CCP)

- ESD Certified

- Six Sigma Certified

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For MEMS Process Engineer (Microelectromechanical Systems Process Engineer)

- Highlight your technical skills and experience in MEMS process development and characterization.

- Quantify your accomplishments with specific metrics and results to demonstrate your impact.

- Showcase your ability to work independently and as part of a team, as well as your problem-solving and analytical skills.

- Include a section in your resume that demonstrates your knowledge of the MEMS industry and your passion for MEMS technology.

Essential Experience Highlights for a Strong MEMS Process Engineer (Microelectromechanical Systems Process Engineer) Resume

- Develop and optimize microfabrication processes for high-performance MEMS sensors and actuators

- Integrate MEMS sensors and actuators into compact packaging solutions

- Collaborate with cross-functional teams to define and implement MEMS-based solutions for various applications

- Supervise and provide technical guidance to junior engineers

- Establish and maintain a cleanroom facility for MEMS research and development

Frequently Asked Questions (FAQ’s) For MEMS Process Engineer (Microelectromechanical Systems Process Engineer)

What is a MEMS Process Engineer?

A MEMS Process Engineer is responsible for designing, developing, and implementing microfabrication processes for MEMS (Microelectromechanical Systems) devices. They work closely with other engineers, scientists, and technicians to ensure that MEMS devices are manufactured to meet specifications and perform as intended.

What are the key skills required for a MEMS Process Engineer?

Key skills for a MEMS Process Engineer include a strong understanding of microfabrication processes, thin film deposition, photolithography, etching, metallization, and packaging. They should also have experience with microfluidics and biological/chemical sensing applications.

What are the career prospects for MEMS Process Engineers?

MEMS Process Engineers are in high demand due to the growing use of MEMS devices in a wide range of industries. They can work in research and development, manufacturing, or quality assurance. With experience, they can advance to management positions or become technical experts in their field.

What is the educational background required for a MEMS Process Engineer?

Most MEMS Process Engineers have a bachelor’s or master’s degree in electrical engineering, materials science, or a related field. Some employers may also require experience in cleanroom operations.

What are the challenges of being a MEMS Process Engineer?

MEMS Process Engineers face a number of challenges, including the need to work with small and delicate structures, the need to achieve high levels of precision and accuracy, and the need to meet strict quality standards.

What are the future trends in MEMS technology?

The future of MEMS technology is bright. MEMS devices are becoming increasingly smaller, more powerful, and more affordable. This is leading to new applications in a wide range of industries, including healthcare, automotive, and telecommunications.